-

Products Detail

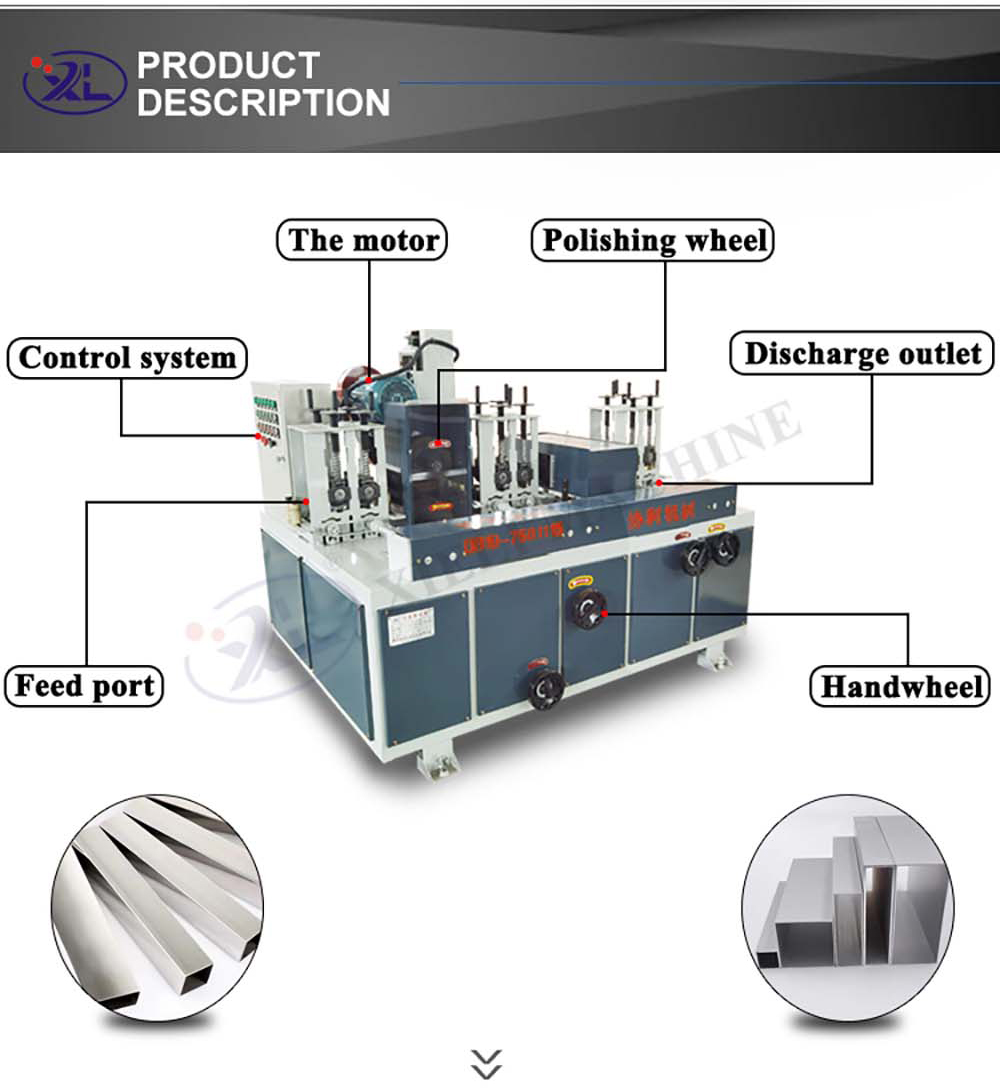

FG series square tube polishing machine

Main purpose and scope of application:

Is suitable for rectangular cross-section profiles such as square tube, square steel, strip steel, hexagonal square steel/square pipe and other metal or non-metallic surface derusting, wire drawing and 8 k mirror polishing, polishing grinding uses the dry form, can choose a variety of grinding materials and tool, (emery cloth Chiba wheel, hemp wheel, nylon wheel, cloth wheel, PVA, and wool wheel), each time can complete the multi-channel different degree of grinding, through reform the polishing wheel shape can also be for polishing profiled section.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

FG-2

FG-4

FG-8

FG-16

FG-24

polished square tube specifications(mm)

120

10*10X120*120

160

10*10X160*160

200

50*50X200*200

300

50*50X300*300

Polishing grinding heads number, (pcs.)

2

4

8

16

24

Machined workpiece length(m)

0.8-12

Steel pipe feed speed(m/min)

0-20(It can be customized according to the user's requirements)

External diameter of matching polishing wheel(mm)

250-300

Grinding head speed(r/min)

2800

Grinding head spindle diameter(mm)

120

32

160

32

200

50

300

50

Grinding head motor power(KW)

120

4

160

5.5

200

7.5

300

11

Grinding head feed mode

Manual / digital display electric (optional)

Dedusting method

Dry fan bag

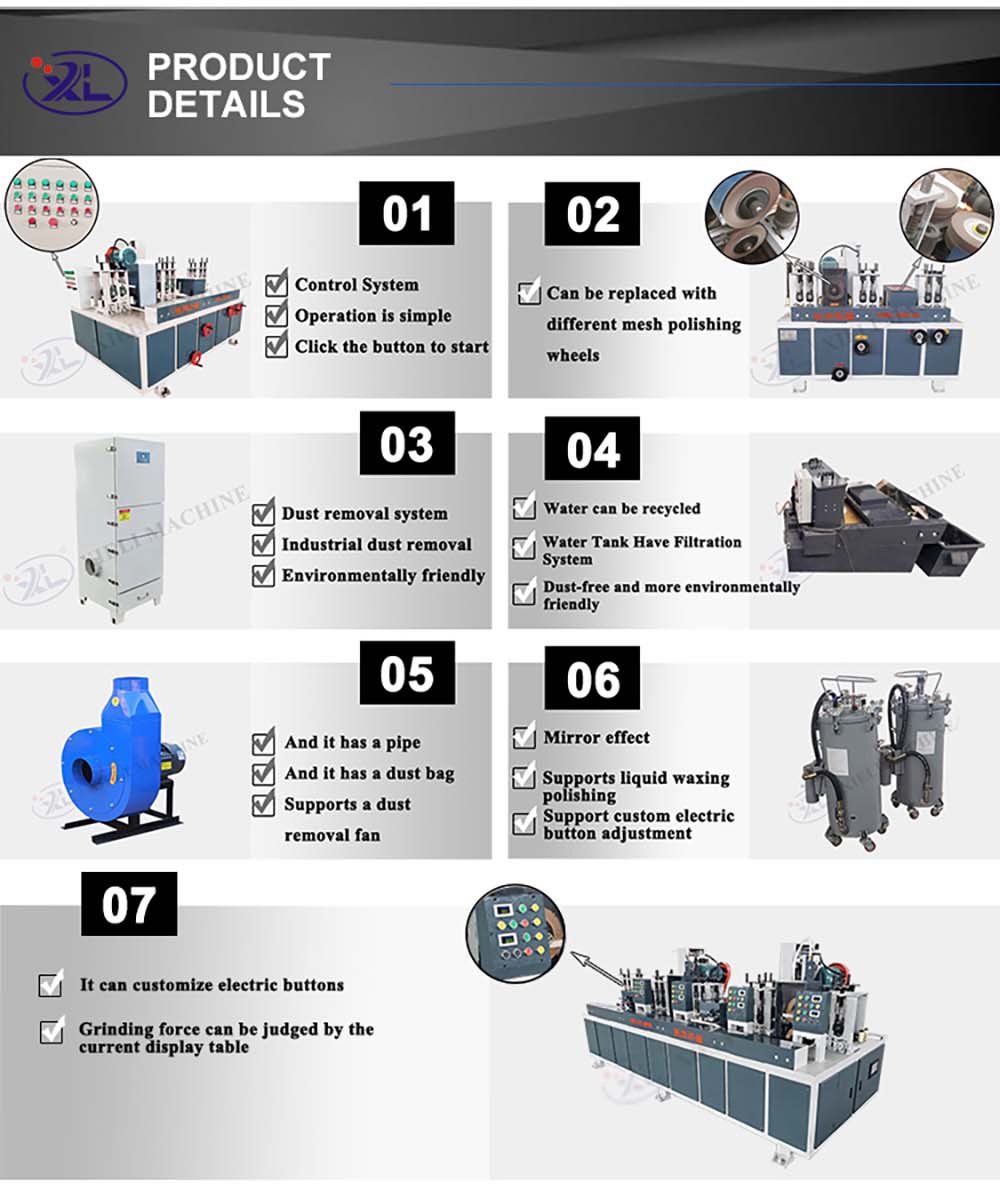

Third, the operation method of the square tube polishing machine

1, Confirm the status of the equipment: before operation, check whether each part is normal and running.

- Feeding: Start the square tube polishing machine, send the square tube to be polished into the equipment, and fix the square tube on the workbench panel by adjusting the positioning parameters.

3, processing: start square tube polishing. In the process of processing, it is necessary to observe the wear of the abrasive belt, grinding wheel and dressing wheel set, and replace it in time to ensure the polishing quality.

4, blanking: after the processing is completed, pay attention to safety, send the polished square pipe to the blanking area, grasp the release time and strength of the clamping device, and remove the polished square pipe from the clamping device.

Second, the working principle of the square tube polishing machine

The core of the square tube polishing machine is a rotating belt grinding wheel, grinding wheel group, dressing wheel group, transmission system and spectral control system and other main modules. After starting the machine, the square tube is transported to the working area of the machine, and after precise positioning and clamping, the processing begins.

- 1.Positioning

There are corresponding positioning holes on the table panel of the square tube polishing machine, and the corresponding positioning parameters are set through the machine control system according to the square tube size. The positioning hole can maintain the stable position of the square tube, and also ensure the accuracy of the processing.

- 2.Processing

In the process of processing, the abrasive belt grinding wheel and dressing wheel group will rotate along each surface of the square tube, and the abrasive belt will polish and grind the horn, corner cutting, hem and other parts, and finally achieve the purpose of polishing process. At the same time, the spectrum control system can monitor the polishing quantity, polishing quality and other parameters in real time, and automatically adjust the processing parameters according to the feedback signal of the sensor to ensure the accuracy and precision of the polishing.

- 3.Discharge materials

After the processing is completed, the square tube is transferred to the blanking area, the clamping device is loosened according to the parameters set by the equipment, and the square tube automatically slides off the blanking area.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- Afriken

- Albanè

- Amharik

- Arab

- Amenyen

- Azerbaydjanyen

- Basque

- Belarisyen

- Bengali

- Bosnyen

- Bulgarian

- Catalan

- Sebuano

- Lachin

- Lachin (Taywann)

- Kòsik

- Kwoasyen

- Czech

- Danwa

- Olandè

- Anglè

- Esperanto

- Estonyen

- Finnish

- Franse

- Frisyen

- Galisyen

- Jòjyen

- Alman

- Grèk

- Gujarati

- Kreyòl Ayisyen

- Aoussa

- Awayen

- Ebre

- Non

- Miao

- Ongwa

- Icelandic

- igbo

- Endonezyen

- Irlandè

- Italyen

- Japonè

- Javanè

- Kannada

- kazakh

- Khmer

- Rwandan

- Koreyen

- Kurdish

- Kyrgyz

- Travay

- Latin

- Latvian

- Lityanyen

- Luxembourgish

- Masedonyen

- Malgach

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolyen

- Myanma

- Nepali

- Nòvejyen

- Nòvejyen

- Occitan

- Pashto

- Pèsyen

- Polonè

- Pòtigè

- Punjabi

- Womenyen

- Ris

- Samoan

- Scottish Gaelic

- Sèb

- Anglè

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenyen

- Somali

- Panyòl

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Tik

- Turkmen

- Ukrainian

- Ourdou

- Ouïghour

- Ouzbèk

- Vyetnamyen

- Welsh

- Èd

- Yiddish

- Zoulou