The Role of Acme Centerless Grinders in Precision Manufacturing

In the fast-paced world of precision manufacturing, achieving unparalleled accuracy and efficiency is essential. Among the various tools that facilitate this process, centerless grinders have earned a prominent place, and Acme Centerless Grinders, in particular, have established themselves as a benchmark in the industry. Acme's commitment to innovation and quality makes their centerless grinding machines indispensable for manufacturers seeking to optimize their production lines.

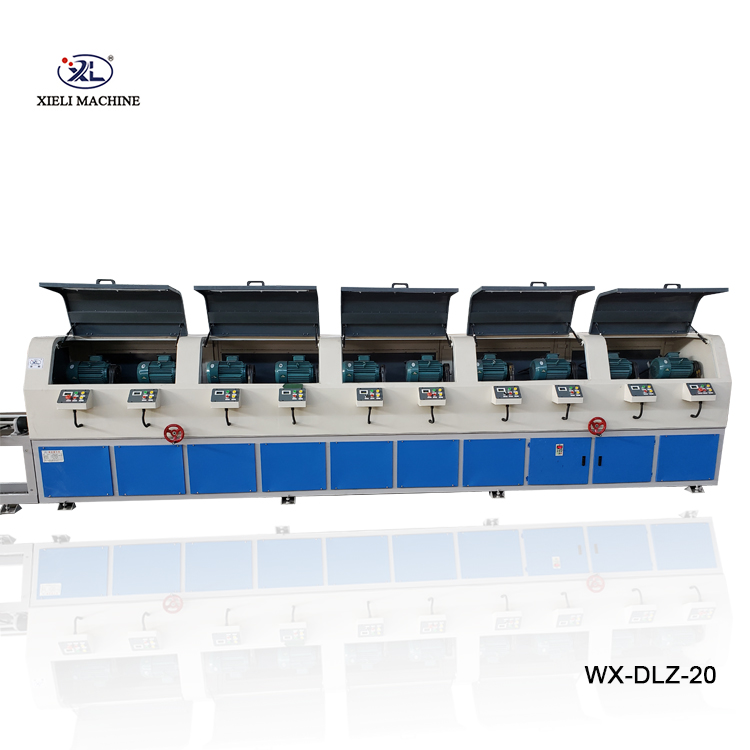

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. It differs from traditional grinding methods due to its unique setup, where the workpiece is held between two grinding wheels the grinding wheel itself and a regulating wheel that controls the speed and movement of the workpiece. This configuration allows for continuous feeding of material without the need for complex fixtures, resulting in high throughput and efficiency.

The Role of Acme Centerless Grinders in Precision Manufacturing

One of the most significant advantages of Acme Centerless Grinders is their ability to achieve superior dimensional accuracy and surface finish. This is critical in industries where precision is paramount. The grinding process allows operators to remove excess material while maintaining tight tolerances, thus ensuring that the end products meet the specific requirements of their applications. Furthermore, Acme's advanced technology incorporates features such as programmable controls and automated feeding systems, which reduce the risk of human error and enhance consistency across production runs.

acme centerless grinder supplier

Acme Centerless Grinders are also engineered with user-friendly interfaces, making them accessible to operators with varying levels of expertise. This ease of use, combined with robust construction, ensures that the machines can withstand the rigors of continuous operation while minimizing downtime. As a result, manufacturers can rely on Acme grinders for sustained performance, leading to increased efficiency and reduced operational costs.

Additionally, Acme recognizes the importance of after-sales support and maintenance services. The company provides comprehensive training programs and technical assistance to help manufacturers maximize the potential of their centerless grinding machines. This commitment to customer service not only enhances the user experience but also fosters long-term relationships between Acme and its clients.

Sustainability is another crucial aspect that many manufacturers prioritize today. Acme Centerless Grinders are designed with energy efficiency in mind, helping companies reduce their carbon footprint while maintaining productivity. By incorporating eco-friendly practices, Acme aligns itself with the growing demand for sustainable manufacturing solutions, an attribute that sets it apart from competitors.

In conclusion, Acme Centerless Grinders play a vital role in the landscape of precision manufacturing. Their ability to deliver high accuracy, consistency, and efficiency makes them a preferred choice for manufacturers across various sectors. By combining innovative technology with an unwavering commitment to quality and customer support, Acme solidifies its position as a leading supplier in the centerless grinding market. As industries continue to evolve and demand for precision components rises, the significance of reliable tools like Acme Centerless Grinders will undoubtedly grow, empowering manufacturers to reach new heights in productivity and quality.