What Are The Types Of Polishing Machines?

Polishing machines come in various types, each designed for specific materials, shapes, and surface finishing requirements. Here are some common types:

Bench Polishing Machines: These are stationary machines with one or two polishing wheels. They are commonly used for small to medium-sized metal parts, jewelry, and tools. Ideal for detailed work and precision polishing.

Rotary Polishing Machines: Featuring rotating drums or barrels, these machines are used for polishing multiple small parts simultaneously. Often used in mass finishing applications, they help smooth and shine parts with minimal labor.

Belt Polishing Machines: These machines use abrasive belts and are suitable for flat surfaces or edges. They're widely used in industries for deburring, grinding, and polishing metal sheets, tubes, and bars.

Vibratory Polishing Machines: These machines use vibration and abrasive media to polish parts placed inside a bowl. They're ideal for delicate or intricate parts, providing even finishes without damage.

Tube/ Pipe Polishing Machines: Specially designed for cylindrical shapes, these machines polish the external surface of tubes and pipes. They can be manual or automated, with single or multi-station setups.

Flat Polishing Machines: Designed for flat workpieces like plates or panels, these machines deliver high precision polishing for a smooth, mirror-like surface.

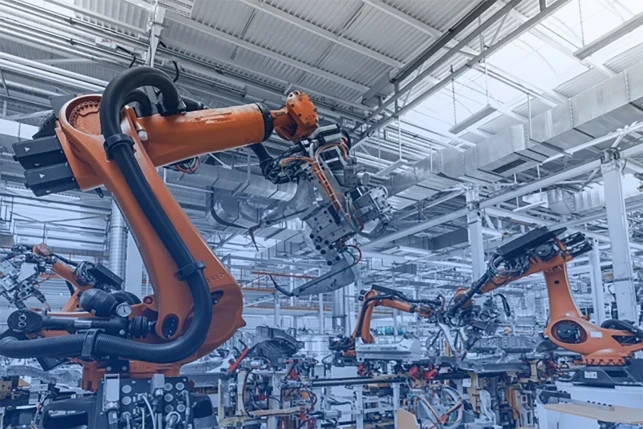

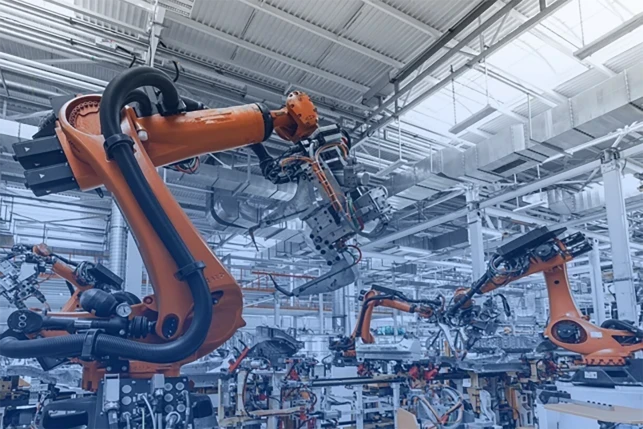

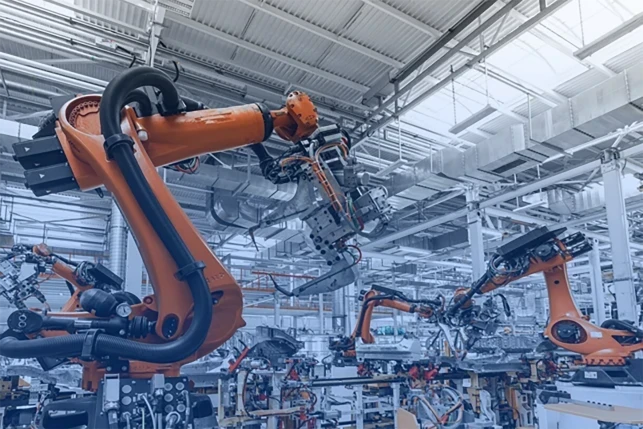

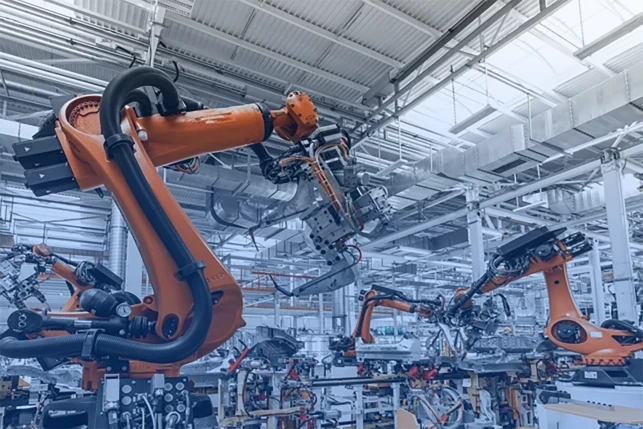

Robotic Polishing Systems: Automated and programmable, these systems use robotic arms for consistent, high-efficiency polishing. They’re ideal for high-volume, complex, or repetitive tasks in automotive or aerospace industries.

Each type of polishing machine serves different purposes based on material type, surface requirements, and production scale.