Wholesale Homemade Centerless Grinders A Guide to DIY Manufacturing

The world of manufacturing is undergoing a significant transformation, driven by innovations in technology and a growing desire for customization. Among the various tools that have gained popularity in specific industrial sectors, centerless grinders stand out for their precision and efficiency. As businesses seek cost-effective solutions, the interest in wholesale homemade centerless grinders is rising. This article explores the benefits, components, and considerations for building your own centerless grinder.

What is a Centerless Grinder?

A centerless grinder is a machine that grinds cylindrical parts without the need for a spindle. Unlike traditional grinders that require workpiece holding systems, centerless grinders operate by placing the workpiece between two wheels a grinding wheel and a regulating wheel. The workpiece is held in place by the friction between these wheels, allowing for precise and efficient grinding. This design is especially beneficial for high-volume production, as it eliminates the need for frequent setup changes and enhances productivity.

Advantages of Homemade Centerless Grinders

1. Cost-Effective Purchasing industrial-grade centerless grinders can be prohibitively expensive. By creating a homemade version, you can significantly reduce initial investment costs. This is particularly advantageous for small businesses or startups operating on a limited budget.

2. Customization Building your own grinder allows for a level of customization that off-the-shelf products may not offer. You can design the grinder to meet specific requirements, whether that involves adjusting the size to handle particular workpieces or modifying it for specialized grinding tasks.

3. Learning Experience Constructing a centerless grinder offers an invaluable opportunity to learn about machining processes, tool design, and mechanical engineering principles. This hands-on experience can enhance your skills and make you more proficient in machining operations.

4. Easier Maintenance Homemade machines are often easier to maintain, as you have an intimate understanding of every component. You can source parts more easily and modify your design based on performance feedback or wear and tear.

Components of a Homemade Centerless Grinder

Creating a centerless grinder requires various components, which can be either purchased or repurposed from existing equipment. Key components include

- Grinding Wheel This wheel removes material from the workpiece. The choice of abrasives and grit size will depend on the materials being processed.

- Regulating Wheel This wheel controls the speed and feed rate of the workpiece, providing stability during the grinding process.

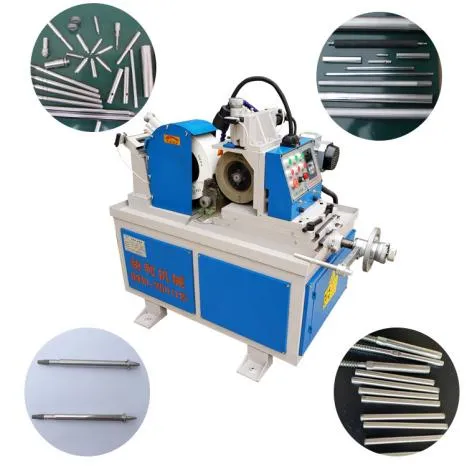

wholesale homemade centerless grinder

- Work Rest A support system that holds the workpiece in place while grinding.

- Base Frame A sturdy base to ensure stability during operation. This can be made from steel or heavy-duty aluminum for durability.

- Motor To drive the grinding and regulating wheels. Selecting an appropriate motor will depend on the desired speed and power requirements of your grinding operations.

- Adjustable Guides For precise adjustment of the workpiece's position during grinding, which is critical for achieving consistent results.

Important Considerations

While the idea of building a homemade centerless grinder is appealing, several considerations must be taken into account

- Precision The accuracy of your grinder is paramount. Ensure that the components are machined to high tolerances for optimal performance.

- Safety Grinding operations can be hazardous. Incorporate safety features, such as proper guarding, emergency stops, and appropriate personal protective equipment (PPE).

- Testing and Calibration After building the grinder, it is essential to test and calibrate it to ensure that it operates correctly and meets your machining specifications.

- Knowledge and Skills Familiarity with machining principles and equipment operation is crucial. If you lack the necessary skills, consider seeking assistance from someone with experience in DIY machine tools.

Conclusion

The pursuit of homemade centerless grinders reflects a broader trend towards customization and cost-efficiency in manufacturing. By investing time and resources into building your own machine, you can reap numerous benefits, including savings, customization, and invaluable learning experiences. However, meticulous planning, a clear understanding of design principles, and prioritizing safety are crucial for success. As more makers and small businesses embrace this approach, the landscape of manufacturing continues to evolve, paving the way for innovation and personalized solutions.