The Role of Tube Buffing Machine Manufacturers in Enhancing Metal Finishing Processes

In the realm of metalworking and finishing, manufacturers constantly seek ways to improve product quality, efficiency, and overall manufacturing processes. One critical component that fulfills these needs is the tube buffing machine. These specialized machines are designed to polish and finish tubular components, ensuring that they not only meet aesthetic requirements but also enhance durability and performance. The role of tube buffing machine manufacturers, therefore, becomes pivotal in the industrial landscape.

Understanding Tube Buffing Machines

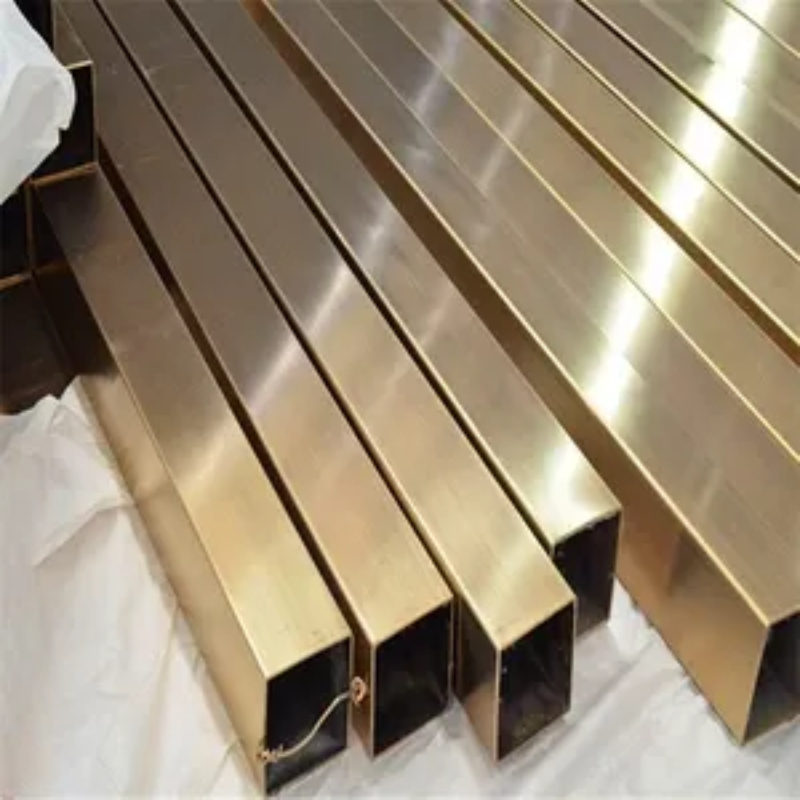

Tube buffing machines are engineered to process metal tubes of various materials, including stainless steel, aluminum, and brass. The primary function of these machines is to apply a fine polishing and buffing action to the surface of the tubes. This process removes imperfections, scratches, and oxidation, resulting in a smooth, shiny finish. The finished product not only looks appealing but also resists corrosion and wear, making it ideal for various applications in sectors such as automotive, aerospace, and construction.

Key Features of Tube Buffing Machines

Manufacturers of tube buffing machines offer a variety of features to cater to the diverse needs of their clients. These machines typically come with adjustable speed settings, enabling operators to control the buffing process according to the material and desired finish. Additionally, many models include automated feeding systems, which enhance efficiency by allowing for continuous operation.

Moreover, tube buffing machines can be equipped with different types of buffing wheels and compounds, allowing flexibility in achieving various surface finishes. Some models are even designed to handle multiple tube sizes and shapes, further broadening their applicability in manufacturing environments.

Innovation and Technology in Tube Buffing

As technology evolves, so too do the capabilities of tube buffing machine manufacturers. Innovations such as programmable logic controllers (PLCs) and touchscreen interfaces have made it easier for operators to manage and monitor the buffing process. These advances not only improve accuracy but also reduce the potential for human error.

tube buffing machine manufacturer

Furthermore, the integration of automation and robotics has enhanced production rates significantly. Automated systems can efficiently handle repetitive tasks, freeing up human operators for more complex activities. This shift towards automation helps manufacturers maintain competitiveness in an increasingly fast-paced market.

The Importance of Quality and Durability

When it comes to tube buffing machines, the emphasis on quality and durability cannot be overstated. Manufacturers that prioritize robust engineering and high-quality materials in their machines are better positioned to deliver products that meet industry standards and withstand the rigors of daily use. Investing in reliable equipment can save companies significant costs in maintenance and replacement over time.

Additionally, a well-manufactured tube buffing machine can achieve consistent results, ensuring that all finished products meet specified tolerances and quality benchmarks. This consistency is crucial in industries where precision is paramount.

Customer Support and Customization

Reputable tube buffing machine manufacturers understand the importance of customer service and support. They often provide comprehensive training programs and resources to help clients maximize the machine's capabilities. This support is particularly beneficial for new operators or companies transitioning to automated solutions.

Moreover, many manufacturers offer customization options to tailor machines to specific processing needs. Whether it’s adjusting machine size, speed, or buffing specifications, the ability to customize equipment ensures that businesses can optimize their production line for efficiency and effectiveness.

Conclusion

In summary, tube buffing machine manufacturers play a vital role in enhancing metal finishing processes across various industries. By providing advanced machines equipped with state-of-the-art technology, they enable manufacturers to produce high-quality, durable products. The focus on innovation, quality, and customer support solidifies their position as essential partners in the metalworking landscape. Companies looking to thrive in a competitive market must recognize the value of investing in quality tube buffing machines, as they are key to achieving a superior finish and enhancing overall production efficiency.