The Importance of Surface Polishing Machines in Modern Manufacturing

In today's fast-paced manufacturing industries, the demand for precision and quality has never been higher. This is where surface polishing machines come into play, serving as essential tools in various sectors, from automotive to aerospace, electronics, and beyond. These machines not only enhance the aesthetic quality of products but also significantly improve their performance and longevity.

Understanding Surface Polishing Machines

Surface polishing machines are specialized tools designed to achieve a smooth and shiny finish on a variety of materials, including metals, plastics, and wood. They utilize abrasives and various polishing techniques to remove imperfections, scratches, and other surface defects. These machines are available in various forms, including manual, semi-automatic, and fully automatic systems, making them adaptable to diverse manufacturing environments.

Applications Across Industries

The versatility of surface polishing machines allows them to find applications across multiple industries. In the automotive sector, for instance, polished surface finishes are essential for both aesthetic appeal and corrosion resistance. Components like engine parts, wheels, and chrome trims benefit greatly from the enhanced finish provided by polishing machines, leading to improved customer satisfaction and extended product life.

In the aerospace industry, the significance of surface polishing escalates even further. Components that require stringent performance standards must have precision finishes to ensure aerodynamic efficiency and minimize friction. Polished surfaces in aircraft parts can lead to weight reduction and improved fuel efficiency, making surface polishing machines crucial for manufacturers aiming to meet fuel consumption regulations and enhance overall performance.

Benefits of Using Surface Polishing Machines

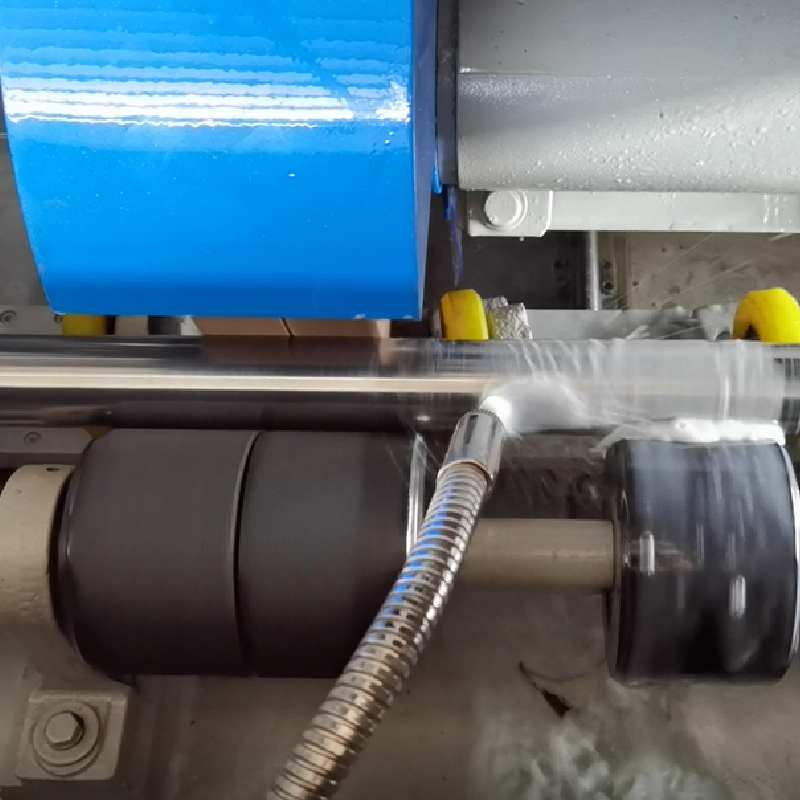

surface polishing machine product

Investing in surface polishing machinery comes with a plethora of benefits. Firstly, these machines help in achieving uniformity in finishes, which is vital for products requiring aesthetic consistency. This uniformity not only boosts the overall quality but also reduces the likelihood of defects, thereby minimizing waste and rework in production processes.

Secondly, the use of surface polishing machines can lead to significant time savings. Manual polishing can be a labor-intensive and time-consuming task. Automated machines can perform the same tasks much faster and with higher precision, allowing manufacturers to streamline processes and improve productivity. This efficiency is especially crucial in high-volume production situations where turnaround times are critical.

Technological Advancements

The evolution of technology has also revolutionized surface polishing. Today's machines often come equipped with advanced features such as programmable settings, touch-screen controls, and real-time monitoring. These innovations allow manufacturers to customize polishing parameters for different materials and desired finishes. Additionally, some modern machines utilize robotics for precision application, ensuring optimal results and reducing the potential for human error.

Moreover, the emergence of eco-friendly polishing solutions, such as water-based compounds and biodegradable abrasives, reflects a growing awareness of sustainability in manufacturing. These advancements help companies minimize their environmental impact while maintaining high-quality standards.

Conclusion

In conclusion, surface polishing machines play a pivotal role in modern manufacturing by enhancing the quality, durability, and aesthetic appeal of products across various industries. Their ability to deliver consistent results in a timely manner makes them an invaluable asset for any manufacturer aiming to remain competitive in today's market. As technology continues to advance, we can expect further innovations in polishing machinery, paving the way for even greater efficiency and environmental sustainability. Whether for automotive, aerospace, or other manufacturing sectors, investing in high-quality surface polishing machines is a step toward achieving excellence and meeting the increasing demands of consumers and regulatory bodies alike.