The Importance of Choosing the Right Polishing Belt Machine Supplier

In the modern manufacturing landscape, precision and quality are paramount. Industries that involve metalworking, woodworking, and surface finishing frequently rely on polishing belt machines to achieve the desired finish and texture on their products. Choosing the right polishing belt machine supplier is crucial for businesses aiming to enhance their production efficiency and product quality. This article explores the significance of selecting a reliable supplier and the factors to consider during the selection process.

Understanding Polishing Belt Machines

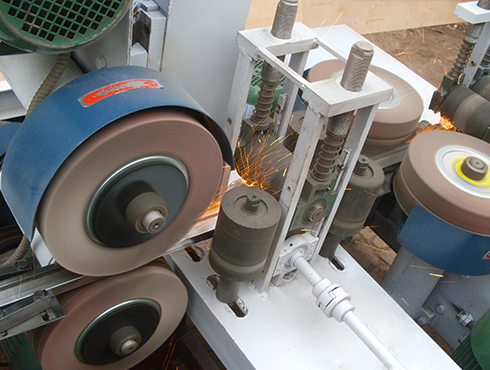

Polishing belt machines are essential tools used to refine the surface of various materials, including metals and wood. These machines utilize abrasive belts to grind, polish, and finish surfaces, making them smooth and visually appealing. Depending on the application, they can be adjusted for different speeds and pressure levels, allowing for customization in polishing operations.

Why Supplier Selection Matters

1. Quality of Machinery A reputable supplier provides high-quality polishing belt machines that meet international safety and performance standards. Machines that are built using durable materials not only last longer but also ensure consistent quality in product output. A trustworthy supplier guarantees that their machines are tested for efficiency and reliability.

2. Technical Support and Service When investing in polishing belt machines, ongoing support is vital. Reliable suppliers often offer comprehensive after-sales services, including installation, maintenance, and repair services. Access to experienced technicians can prevent costly downtimes and ensure that machines operate at optimal levels.

3. Customized Solutions Different industries may have unique polishing needs. A good supplier will understand these requirements and offer customized solutions. Whether it’s altering the machine specifications or providing tailored abrasive belts, a responsive supplier can help businesses achieve specific polishing results.

4. Competitive Pricing Price is often a deciding factor when selecting a supplier. However, the cheapest option is not always the best. Instead, businesses should consider the overall value, which includes the quality of the machine, the level of service, and the warranty offered. Suppliers that provide a good balance of quality and affordability tend to be the best choice.

polishing belt machine supplier

5. Reviews and Reputation Researching potential suppliers through online reviews, industry forums, and recommendations can provide crucial insights into their reputation. A supplier known for excellence will have positive feedback from past customers and a track record of reliable service. Engaging with existing customers can also reveal information about their experience with the supplier.

Factors to Consider When Choosing a Supplier

- Experience and Expertise Look for suppliers that have extensive experience in the industry. Knowledge of modern advancements in polishing technology and a commitment to innovation can indicate a supplier’s potential to meet your evolving needs.

- Diversity of Products A supplier that offers a range of polishing belt machines and related accessories gives businesses options. This diversity allows for better compatibility with existing tools and the ability to scale operations as needed.

- Geographical Location Proximity can impact service efficiency. Selecting a local supplier can result in quicker response times for service and support, which can be critical during machine breakdowns.

- Warranty and Return Policy Reviewing a supplier's warranty and return policy is essential. A reliable warranty indicates the supplier’s confidence in their product’s longevity and performance. It also provides peace of mind for the buyer.

Conclusion

Selecting the right polishing belt machine supplier is a critical decision that can significantly influence a business's production capabilities and product quality. By considering factors such as machine quality, technical support, customization options, pricing, and supplier reputation, companies can find a partner that not only meets their current needs but also supports future growth. In a competitive market, investing time in choosing the right supplier can pave the way for improved efficiency, enhanced quality, and ultimately, greater customer satisfaction.