The Rise of OEM Tube Polishing Machines in the UK Market

In recent years, the manufacturing landscape in the UK has witnessed significant advancements, particularly in the field of metal finishing. One notable innovation that has emerged is the OEM tube polishing machine. These machines have become integral to achieving high-quality finishes on metal tubes across various industries, including automotive, aerospace, and furniture manufacturing.

Understanding OEM Tube Polishing Machines

OEM, or Original Equipment Manufacturer, refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of tube polishing machines, OEMs design and build machinery that is tailored for specific applications, ensuring optimum performance and efficiency. These machines are engineered to handle a variety of tube sizes and materials, making them a versatile option for businesses.

The primary function of a tube polishing machine is to enhance the aesthetic and functional qualities of metal surfaces. By utilizing adjustable speed settings, specialized polishing pads, and various abrasive materials, these machines can remove imperfections such as scratches, oxidation, and other surface defects. The result is a smooth, reflective finish that meets industry standards.

Market Demand in the UK

As industries evolve, the demand for high-quality metal finishes continues to rise. In the UK, sectors such as automotive manufacturing require polished tubes for both aesthetic appeal and functional purposes, as tougher industry regulations mandate quality compliance. Consequently, the market for OEM tube polishing machines has flourished. Companies increasingly turn to these machines to reduce manual labor costs, enhance production speed, and maintain consistency in product quality.

Moreover, manufacturers are now placing a premium on sustainability. OEM tube polishing machines can be designed with energy efficiency in mind, utilizing advanced technologies that consume less power and generate less waste. The incorporation of eco-friendly polishing compounds reflects a growing commitment to sustainable manufacturing practices, further driving the demand for these machines in the UK.

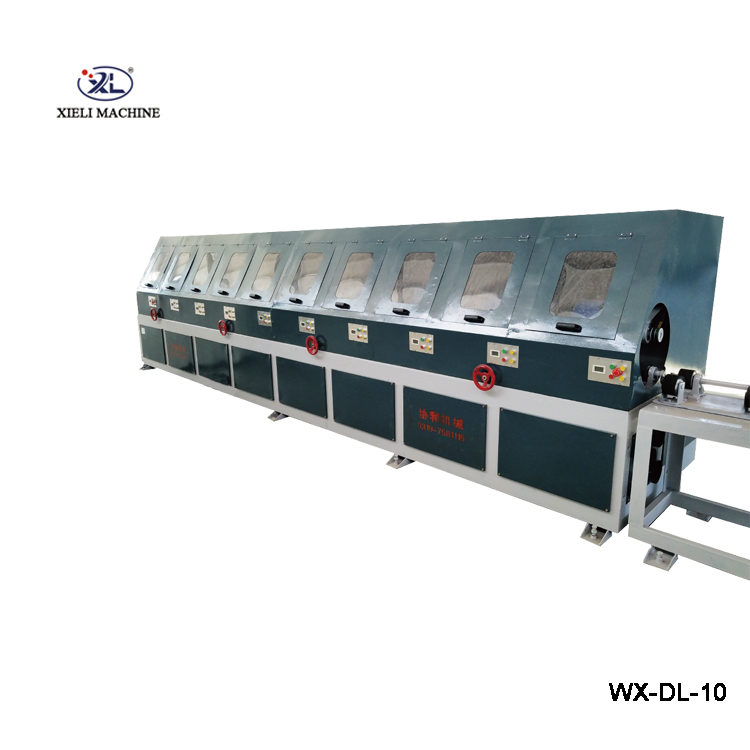

oem tube polishing machine uk

Technological Innovations

The evolution of technology has allowed OEM tube polishing machines to become more sophisticated. Modern machines come equipped with computer numerical control (CNC) capabilities, which allows for precise programming of polishing operations. This level of automation not only enhances the accuracy of the polishing process but also significantly reduces the risk of human error.

Additionally, some manufacturers have begun integrating IoT capabilities into their polishing machines. This innovation allows businesses to monitor machine performance and maintenance needs in real time, ensuring optimal operational efficiency. Predictive maintenance powered by data analytics can lead to reduced downtime, ultimately boosting productivity and profitability.

Challenges and Solutions

Despite the promising growth of the OEM tube polishing machines market in the UK, several challenges persist. Small to medium-sized enterprises (SMEs) may find the initial investment in such advanced machinery to be a barrier. However, leasing options and government grants aimed at supporting manufacturing innovation can provide feasible alternatives for SMEs to access these technologies.

Furthermore, ensuring that personnel are adequately trained to operate sophisticated machines is crucial. Companies are increasingly investing in training programs to upskill their workforce, thus overcoming the barrier of technical proficiency.

Conclusion

The demand for OEM tube polishing machines in the UK is a reflection of the nation's commitment to high-quality manufacturing and innovation. As industries continue to prioritize efficiency, sustainability, and precision, the role of advanced polishing technologies will only grow. Businesses that invest in OEM tube polishing machines today are likely to set themselves apart in a competitive market, reaping the benefits of superior efficiency and product quality for years to come.