The World of OEM Centerless Valve Grinders

In the competitive landscape of manufacturing, precision and efficiency are paramount, especially in industries that require high-quality components, such as automotive, aerospace, and industrial machinery. One of the critical processes in achieving this precision is valve grinding. Among the various types of valve grinding machines, OEM centerless valve grinders stand out for their unique capabilities and advantages.

Understanding Centerless Grinding

Centerless grinding is a machining process that allows for the grinding of cylindrical shapes without the need for a vice or fixture. In traditional grinding processes, the workpiece is usually supported between two centers, making setup rather complex. However, centerless grinding utilizes a different approach. The workpiece is placed between a grinding wheel and a regulating wheel, which keeps the part in the right position during the grinding operation.

This configuration enables easier loading and unloading of parts and allows for high-speed production rates, making centerless grinding an attractive option for manufacturers who need to produce large volumes of parts efficiently.

The Importance of OEM in Centerless Valve Grinders

Original Equipment Manufacturers (OEMs) play a crucial role in the development and supply of centerless valve grinders. An OEM centerless valve grinder is specifically designed to meet the unique requirements of valve manufacturing. These machines are built with advanced technology that ensures superior accuracy, repeatability, and durability.

For manufacturers, choosing an OEM grinder means investing in quality and reliability. OEMs have the expertise and experience to deliver machines that not only meet but often exceed industry standards. They conduct rigorous testing and quality assurance processes to ensure that each machine operates at optimal performance levels.

Key Features of OEM Centerless Valve Grinders

1. Precision Engineering OEM centerless valve grinders are designed with high-precision components that minimize tolerances. This precision is crucial in applications where valve performance significantly impacts the overall functionality of engines and machinery.

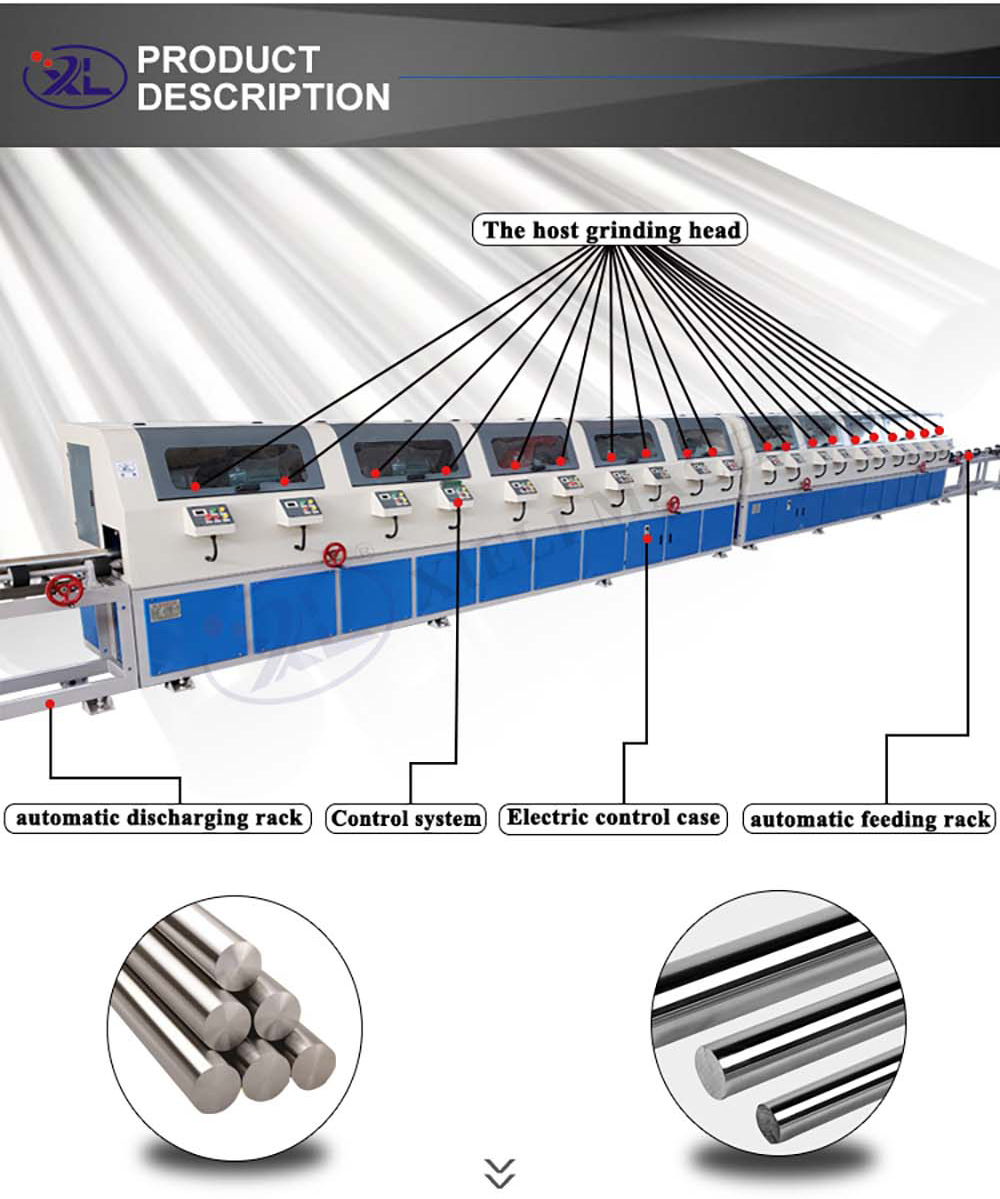

oem centerless valve grinder

2. Customization Options Many OEMs offer customizable solutions that cater to specific needs, including grinding wheel size, workpiece dimensions, and production volume. This flexibility allows manufacturers to optimize their production process.

3. Advanced Control Systems Modern OEM centerless grinders are equipped with sophisticated control systems that make programming and operation user-friendly. These systems can integrate with existing production lines, ensuring seamless workflows and minimizing downtime.

4. Reduced Cycle Times With the ability to grind multiple parts simultaneously and the streamlined loading/unloading processes, OEM centerless grinders can significantly reduce cycle times, thereby increasing overall productivity.

5. Durability and Low Maintenance OEMs utilize high-quality materials and robust construction methods in their grinders. This not only enhances the machine's lifespan but also reduces maintenance costs in the long run.

Benefits to Manufacturers

Investing in OEM centerless valve grinders provides numerous benefits to manufacturers. With the ability to produce precise, high-quality valves quickly, companies can improve their turnaround times and responsiveness to market demands. The consistency offered by these grinders helps to reduce scrap rates, which is crucial for maintaining profitability in a competitive market.

Moreover, by taking advantage of the advances in grinding technology, manufacturers can focus on innovation, developing new products that meet the evolving needs of their customers. The reliability of OEM machinery also means that companies can plan their production schedules with confidence, knowing that their equipment will perform as expected.

Conclusion

OEM centerless valve grinders represent a vital investment for manufacturers seeking to enhance their production capabilities. With their superior precision, advanced technology, and customization options, these machines empower companies to meet the demands of modern manufacturing. As industries continue to evolve and require increasingly sophisticated components, the significance of OEM centerless valve grinders will undoubtedly grow, solidifying their place as a cornerstone of high-quality valve production. By choosing OEM solutions, manufacturers can position themselves for success in a fast-paced and ever-changing marketplace.