The Evolution of Centerless Grinding Machines A New Era in Precision Engineering

Centerless grinding has been a cornerstone of manufacturing processes for decades, facilitating the precise shaping of cylindrical objects. As industries demand higher precision, efficiency, and productivity, the introduction of new centerless grinding machine products marks a significant evolution in this foundational technology. This article explores the advancements in centerless grinding machines, their applications, and the benefits they bring to modern manufacturing.

Understanding Centerless Grinding

At its core, centerless grinding is a manufacturing process that eliminates the need for a spindle to hold the workpiece in place. Instead, the workpiece is supported by a combination of a grinding wheel and a regulating wheel. This method allows for the continuous action of grinding, resulting in high throughput and consistent precision. Unlike traditional grinding, where the workpiece must be centered, centerless grinding can process multiple pieces simultaneously, making it an ideal choice for mass production.

The New Wave of Centerless Grinding Machines

Recent technological advancements have led to the development of new centerless grinding machines that incorporate advanced features designed to enhance performance. These innovations include

1. Automated Controls Modern centerless grinding machines are now equipped with state-of-the-art automation technology. This allows operators to program the machines for various grinding cycles, reducing manual intervention and minimizing human error. Automated systems can adjust parameters in real-time, ensuring consistent quality and improving efficiency.

2. Adaptive Grinding New machines incorporate adaptive grinding features that utilize sensors to monitor the grinding process continuously. By analyzing feedback from the grinding operation, these machines can automatically adjust speed, pressure, and grinding wheel position to maintain optimal performance, thus reducing the risk of defects.

3. Enhanced Ergonomics The latest designs emphasize user-friendly interfaces and ergonomic setups. This shift not only improves operator safety but also reduces fatigue and training time for new personnel. The intuitive controls facilitate quicker adjustments and modifications, allowing manufacturers to respond faster to varying production demands.

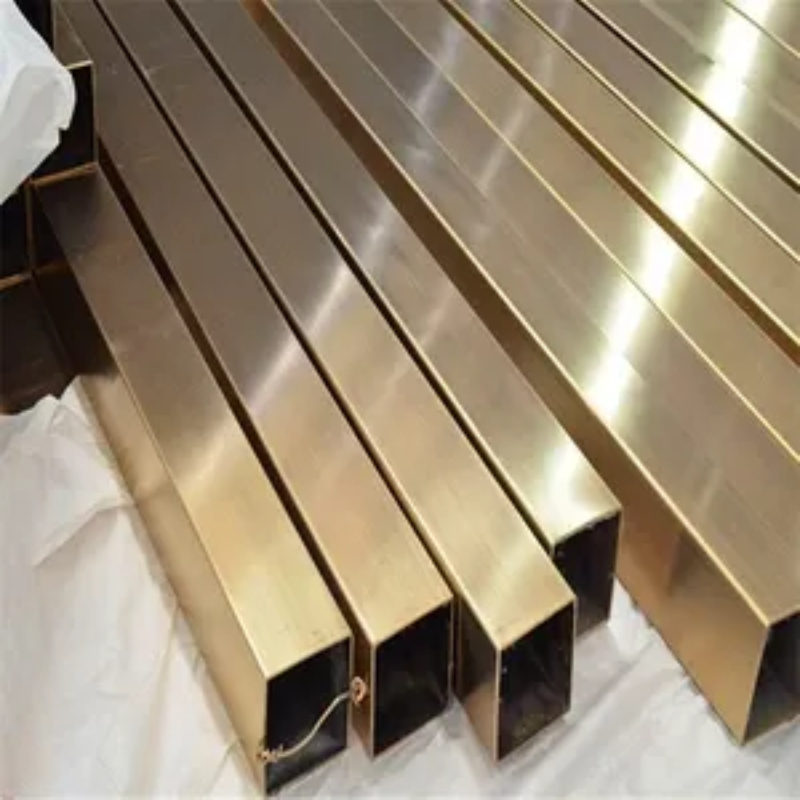

new centerless grinding machine product

4. Sustainable Practices With growing emphasis on sustainability, manufacturers are now producing machines with energy-efficient designs and lower waste output. Innovations include regenerative drive systems and improved coolant management, leading to reduced environmental impact while maintaining performance.

5. Precision Engineering New centerless grinding machines offer improved precision and tolerances. Advanced grinding methods and better wheel materials enable tighter specifications, which are crucial for industries such as aerospace, automotive, and medical device manufacturing. These devices ensure that finished products meet stringent quality standards.

Applications Across Industries

The versatility of centerless grinding machines makes them applicable across a broad spectrum of industries. In automotive manufacturing, for instance, these machines are used to produce high-precision components such as fuel injectors and crankshafts. The medical industry relies on centerless grinding to create parts with strict tolerance requirements for surgical instruments and implants. Additionally, the aerospace sector benefits from the capability to grind lightweight, high-strength components essential for aircraft performance and safety.

The Future of Centerless Grinding

As technology continues to evolve, so will the capabilities of centerless grinding machines. Future developments may include the integration of artificial intelligence and machine learning for predictive maintenance, enhancing the machines' operational life, and preventing costly downtimes. Furthermore, advancements in materials technology may lead to the creation of grinding wheels that can operate at higher speeds and for longer durations without degradation.

Conclusion

The emergence of new centerless grinding machine products represents a significant leap forward in the machining landscape. With their advanced features, increased efficiency, and environmentally friendly designs, these machines are set to redefine precision engineering. As industries continuously strive for improvement in productivity and quality, centerless grinding machines will play a pivotal role in shaping the future of manufacturing. Embracing these innovations not only enhances operational capabilities but also ensures that manufacturers remain competitive in an increasingly demanding market.