A Comprehensive Guide to Metal Polishing Machine Price Suppliers

Metal polishing is an essential process in various industries, including automotive, aerospace, and manufacturing. It enhances the aesthetic appeal of metal products while improving their resistance to corrosion and wear. As the demand for polished metal components continues to rise, the need for efficient and cost-effective metal polishing machines has grown significantly. This article explores the factors affecting the prices of metal polishing machines and how to find reliable suppliers.

Understanding Metal Polishing Machines

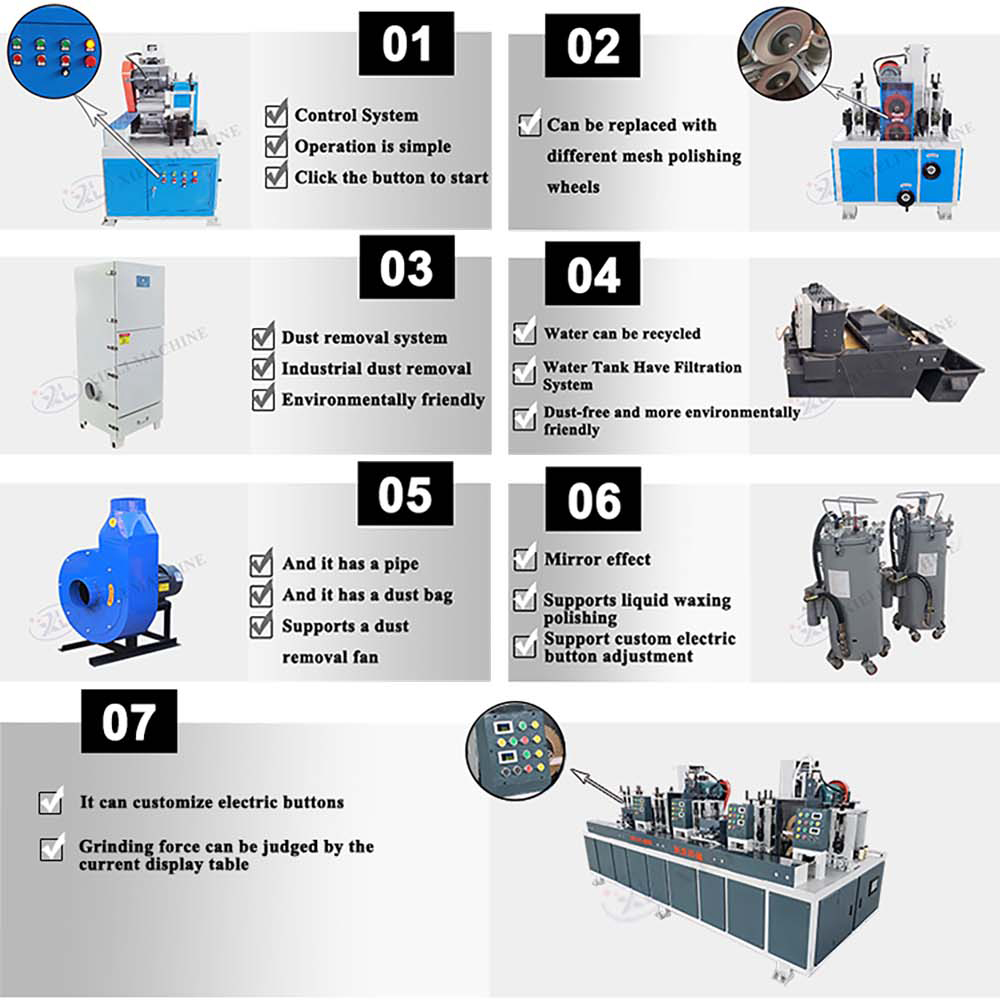

Metal polishing machines vary in type, size, and functionality. They can range from small handheld devices ideal for DIY projects to large industrial machines designed for mass production. Common types of polishing machines include vibrating polishers, rotary polishers, and belt polishers. The choice of machine often depends on the materials being polished and the desired finish.

Factors Affecting Prices

1. Machine Type and Size The most significant factor determining the price of a metal polishing machine is its type and size. Smaller, portable machines typically cost less than large, industrial-grade machines that can handle high volumes and heavy workloads.

2. Quality of Build and Technology The materials used in construction and the technology employed can also impact the price. Machines made from high-quality materials and equipped with advanced features such as programmable controls or automatic polishing cycles tend to be more expensive.

3. Customization Options Some suppliers offer customizable machines tailored to specific polishing needs. Customization can significantly affect the price. Machines designed for specific applications, such as jewelry polishing or automotive parts, may come at a premium.

4. Brand Reputation Well-established brands often charge higher prices due to their reputation for quality and reliability. Investing in a reputable brand can provide long-term benefits, including superior performance and after-sales service.

5. Market Demand Like any other product, the market's supply and demand dynamics can influence the price of metal polishing machines. During periods of high demand, prices may rise, while economic downturns could lead to price reductions.

6. Geographic Location The location of the supplier and the purchasing company can also impact costs. Shipping fees and import taxes can add to the overall price, especially for international suppliers.

metal polishing machine price supplier

Finding Reliable Suppliers

When searching for metal polishing machine price suppliers, consider the following steps

1. Research Online Utilize online platforms and marketplaces to compare prices, read reviews, and evaluate different suppliers. Websites like Alibaba, Made-in-China, and TradeIndia can provide a wide range of options from various manufacturers.

2. Industry Trade Shows Attending trade shows and exhibitions related to manufacturing and metalworking can provide opportunities to meet suppliers in person, see the machines in action, and negotiate prices.

3. Request Quotes Don’t hesitate to reach out to multiple suppliers to request quotes. This will allow you to compare prices, features, and warranty options before making a decision.

4. Check References Before finalizing a purchase, ask for references or testimonials from previous customers to ensure the supplier's reliability and quality of service.

5. Evaluate Warranty and Support Consider suppliers that offer good warranty terms and after-sales support. This can provide peace of mind in case of any operational issues post-purchase.

Conclusion

Investing in a metal polishing machine is a crucial decision that requires careful consideration of various factors, including price, type, and supplier reliability. By understanding the elements that influence pricing and actively researching potential suppliers, you can find the right machine that meets your needs without exceeding your budget. Whether you are looking for an entry-level device or a high-quality industrial machine, the right supplier will play a pivotal role in your success in metal polishing.

This guide serves as a valuable resource for anyone looking to navigate the market for metal polishing machines and make informed purchasing decisions.