Finding an inner wall polishing machine factory that can provide high-quality products and services requires careful investigation and selection. With the rapid advancements in industrial technology, the demand for specialized machinery such as inner wall polishing machines has increased significantly. This article provides insights into the factors you should consider when choosing the right factory, as well as highlighting what makes a factory reliable and efficient in producing inner wall polishing machines.

When evaluating a factory for their inner wall polishing machines, it’s critical to consider the factory’s level of experience. A factory with extensive experience in manufacturing polishing machines indicates a depth of knowledge and proficiency in producing high-performance and reliable equipment. Experienced manufacturers are typically familiar with industry trends and possess the ability to implement the latest technological innovations into their machinery, ensuring that the products are not only advanced but also meet the ever-evolving demands of their clients.

Expertise is another essential factor when it comes to selecting an inner wall polishing machine factory. A factory that specializes in this niche will be more equipped to understand and address the specific needs and challenges associated with inner wall polishing. Such factories tend to have a dedicated team of engineers and technicians who are well-versed in designing and improving machinery tailored to different industrial applications. They are also more likely to provide custom solutions that can enhance the efficiency and effectiveness of your operations.

To ensure authoritativeness, it’s advisable to choose a factory that holds various certifications and complies with international quality and safety standards. Certifications like ISO 9001 not only reflect a commitment to quality management and continuous improvement but also assure customers of the factory’s credibility and reliability. Authoritative factories often participate in industry seminars and conferences, sharing their knowledge and contributing to the development of polishing machine standards worldwide.

Trustworthiness in a factory is built over time through consistent product quality, excellent customer service, and transparent business practices. Reliable factories typically offer warranties and after-sales support, including maintenance services and the availability of spare parts. They maintain open communication channels, ensuring that clients receive timely updates throughout the purchasing process. Testimonials and reviews from previous clients are a good indicator of a factory’s trustworthiness, as they reflect the experiences of others who have worked with them.

inner wall polishing machine factory

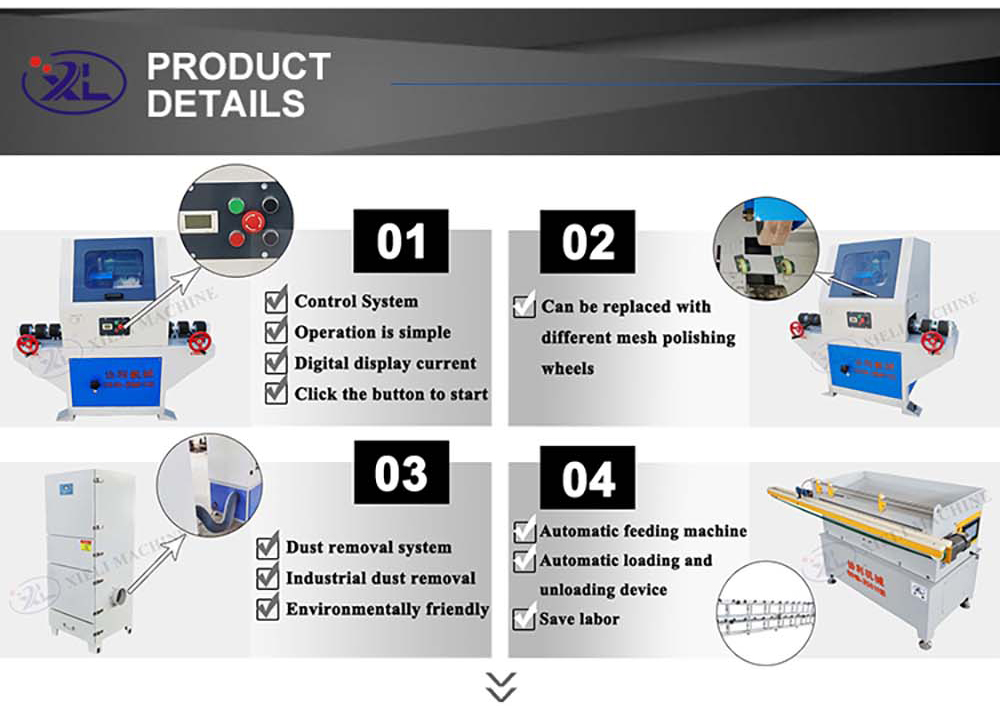

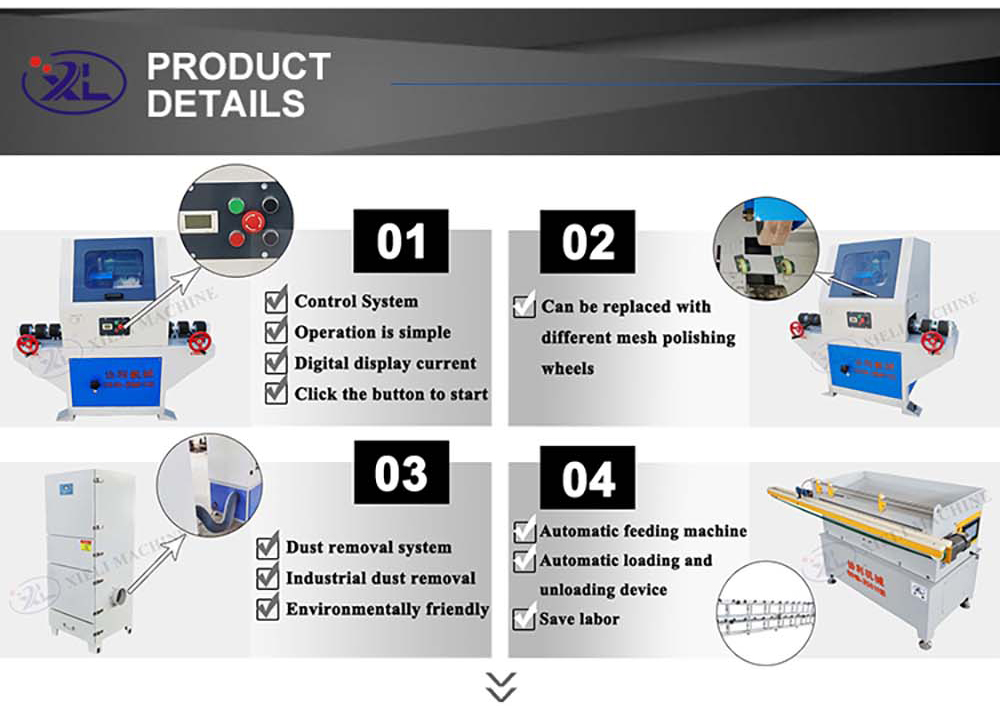

In terms of product offerings, an ideal inner wall polishing machine factory should provide a range of machines that cater to different material types and sizes. They should utilize high-quality materials and components in their machines to ensure durability and long-term performance. The factory should also be innovative, showcasing their ability to integrate new technologies like automation and advanced control systems into their products.

Furthermore, evaluating the production capabilities of the factory is essential. A factory equipped with modern infrastructure and technology ensures that they can handle large orders and are capable of scaling up production when needed. Advanced manufacturing techniques, such as CNC machining and precision engineering, are indicative of a factory that is committed to producing top-tier products.

A factory's location might also be a consideration depending on logistical preferences. Factories with easy access to transportation networks can typically offer more efficient delivery services. However, it’s important to balance convenience with other critical factors such as quality and cost.

In summary, when selecting an inner wall polishing machine factory, prioritize those with proven experience, specialized expertise, and a strong reputation for quality and reliability. Authoritative and trustworthy factories will ensure that you receive machines that not only meet but exceed industry standards, providing you with a competitive edge in your business operations. By conducting thorough research and relying on well-rounded evaluation criteria, you can make informed decisions that will drive your success in the polishing machine market.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.