-

Products Detail

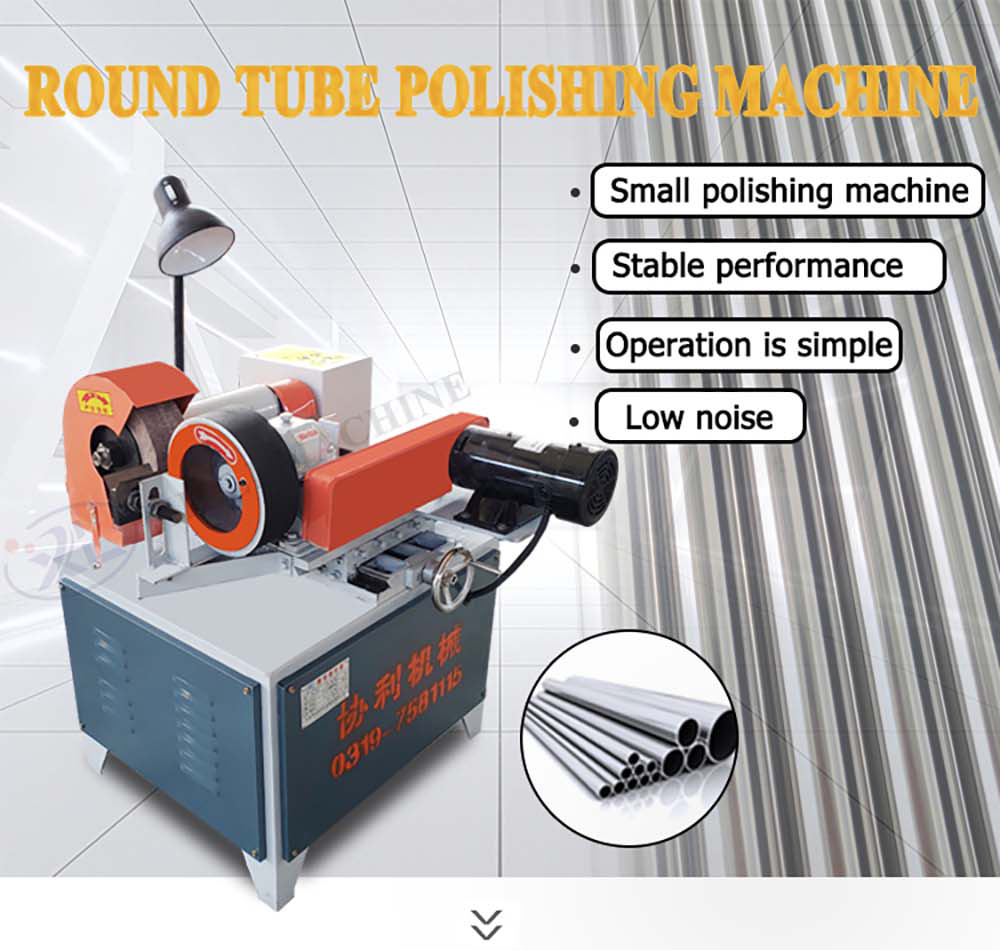

WX Series Single Grinding Head Round Tube Polisher

Main purpose and scope of application:

Round tube polisher is mainly used in hardware manufacturing, vehicle parts,hydraulic cylinders, steel and wood furniture, instrument machinery, standard parts and electroplating industries before and after the rust and polishing. Round tube polishing machine is the best

choice for round tube, round rod, long and thin shaft polishing. Round tube polisher can be installed a variety of polishing wheels, such as Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA, etc., guide wheel stepless speed control, simple and convenient operation, optimize the steel structure to make the performance more stable, the fan can be installed with the fan mouth.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

WX Series Single Grinding Head Round Tube Polisher

Project

Model

WX-A1-60

WX-A1-120

WX-A2-60

WX-B1-60

WX-B1-120

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

3.5

4.5

6

4.5

4.5

Polishing wheel

specification(mm)

250*40*32(Width can be assembled)

Guide wheel

specification(mm)

230*80

230*100

230*120

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

0-120(Stepless speed regulation)

Machining diameter(mm)

1-120

50-180

1-120

1-120

50-180

Processing efficiency(m/min)

0-8

Surface roughness (um)

Ra 0.02

Wet water cycle dust removal

optional

have

optional

Dry fan dust removal

optional

have

optional

Machine tool total weight about(kg)

320

460

860

520

620

Equipment overall dimension(m)

0.7*0.8*1.0

0.8*0.9*1.0

1.2*0.9*1.5

1.0*0.9*1.0

1.1*1.0*1.0

The whole process is fast and efficient, saving time and labor, which can not only improve production efficiency, but also reduce labor costs and energy consumption. The polishing effect of the round tube pipe polishing machine is very good, and the rough surface can be treated into a smooth and flat surface, which can be applied to round pipes tubes of various materials, such as stainless steel pipe, aluminum alloy pipe, copper pipe and so on. It can meet the requirements of surface quality and finish, and extend the service life of the product while ensuring the processing quality. In short, the round tube pipe polishing machine has a variety of advantages, including high efficiency, high quality, easy operation and low energy consumption, and is an indispensable equipment in the field of circular pipe processing.Through reasonable maintenance and maintenance, the round tube polishing machine can perform processing operations stably for a long time, effectively improving production efficiency and product quality.

The round tube pipe polishing machine can also achieve different polishing methods, such as bright surface polishing, mirror polishing, burr removal and so on. According to different needs, different polishing methods can be selected to achieve better processing results. Moreover, the round tube polisher is robust, assembled from high-quality materials and parts, and can run for a long time without problems. In daily maintenance, only simple cleaning and maintenance are needed to keep the equipment working normally. In general, round tube polishers can provide efficient, precise and high-quality processing solutions for round tube processing. It can not only improve processing efficiency and product quality, but also reduce labor costs and waste generated, and is a very valuable mechanical equipment.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- 非洲

- 阿爾巴尼亞語

- 阿姆哈拉語

- 阿拉伯

- 亞美尼亞語

- 亞塞拜然

- 巴斯克

- 白俄羅斯語

- 孟加拉

- 波士尼亞語

- 保加利亞語

- 加泰隆尼亞語

- 宿霧語

- 中國

- 中國(台灣)

- 科西嘉

- 克羅埃西亞語

- 捷克語

- 丹麥語

- 荷蘭語

- 英語

- 世界語

- 愛沙尼亞語

- 芬蘭

- 法語

- 弗里斯蘭語

- 加利西亞語

- 喬治亞

- 德文

- 希臘文

- 古吉拉特語

- 海地克里奧爾語

- 豪薩語

- 夏威夷

- 希伯來文

- 不

- 苗族

- 匈牙利

- 冰島語

- 伊博語

- 印尼

- 愛爾蘭人

- 義大利語

- 日本人

- 爪哇語

- 卡納達語

- 哈薩克

- 高棉語

- 盧安達

- 韓國人

- 庫德

- 吉爾吉斯斯坦

- 勞動

- 拉丁

- 拉脫維亞語

- 立陶宛語

- 盧森堡語

- 馬其頓語

- 馬爾加什

- 馬來語

- 馬拉雅拉姆語

- 馬爾他語

- 毛利人

- 馬拉地語

- 蒙

- 緬甸

- 尼泊爾語

- 挪威

- 挪威

- 奧克西坦語

- 普什圖語

- 波斯語

- 拋光

- 葡萄牙語

- 旁遮普語

- 羅馬尼亞語

- 俄文

- 薩摩亞

- 蘇格蘭蓋爾語

- 塞爾維亞

- 英語

- 紹納語

- 信德語

- 僧伽羅語

- 斯洛伐克語

- 斯洛維尼亞語

- 索馬利亞

- 西班牙語

- 巽他語

- 斯瓦希里語

- 瑞典

- 他加祿語

- 塔吉克

- 泰米爾語

- 韃靼人

- 泰盧固語

- 泰國

- 土耳其

- 土庫曼人

- 烏克蘭

- 烏爾都語

- 維吾爾

- 烏茲別克語

- 越南語

- 威爾斯語

- 幫助

- 意第緒語

- 祖魯