The Importance of High-Quality Steel Pipe Polishing Machines

In the world of manufacturing and metalworking, the quality of the final product is paramount. One critical aspect of ensuring that steel pipes meet industry standards is the polishing process. High-quality steel pipe polishing machines play a vital role in achieving the desired surface finish and enhancing the overall performance of steel pipes. This article explores the features, benefits, and advancements of these machines, underscoring their significance in today's manufacturing landscape.

What is a Steel Pipe Polishing Machine?

A steel pipe polishing machine is a specialized equipment designed to remove imperfections and surface irregularities from steel pipes. This process not only improves aesthetics but also enhances the corrosion resistance and fatigue strength of the pipes. The polishing machine works by utilizing a combination of mechanical and chemical processes, including abrasive polishing, buffing, and sometimes even electropolishing, to achieve a smooth, mirror-like finish.

Key Features of High-Quality Polishing Machines

1. Robust Construction High-quality polishing machines are built with durable materials such as stainless steel and heavy-duty components, ensuring longevity and resilience even under continuous operation.

2. Advanced Technology Many modern polishing machines incorporate advanced technology such as computer numeric control (CNC) systems, which allow for precise control over the polishing process. This technology enables the machine to adjust the speed, pressure, and technique based on the specific requirements of different pipe specifications.

3. Versatility High-quality polishing machines are designed to handle various pipe sizes and types, making them versatile for different industrial applications, from construction to automotive manufacturing.

4. User-Friendly Interfaces Many new models come equipped with intuitive interfaces and programmable settings, allowing operators to easily set parameters and monitor the polishing process, enhancing productivity and ensuring quality control.

5. Environmental Considerations Advanced polishing machines are increasingly designed with environmental sustainability in mind. They utilize closed-loop systems to minimize waste and enhance the recycling of abrasive materials.

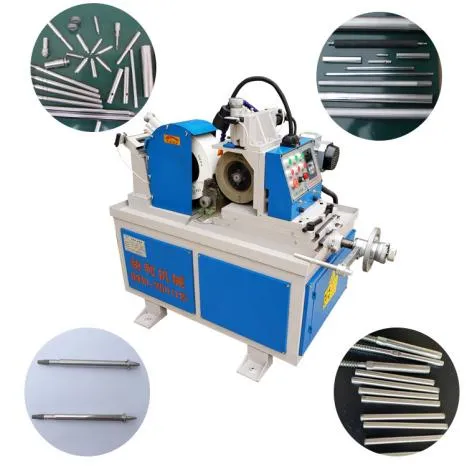

high quality steel pipe polishing machine

Benefits of Using High-Quality Polishing Machines

1. Enhanced Surface Finish The most obvious benefit of using a high-quality polishing machine is the superior surface finish it provides. A polished surface not only looks better but also enhances performance in applications where pipes are subjected to harsh conditions.

2. Increased Corrosion Resistance Polished pipes are less likely to harbor contaminants and moisture, which contribute to corrosion. This longevity is particularly important in industries like oil and gas, where the integrity of pipes is crucial.

3. Improved Performance Smooth surfaces reduce friction, which is essential in applications involving fluid flow. Polished steel pipes can improve flow rates and reduce energy consumption.

4. Cost Efficiency Investing in high-quality polishing machines can lead to significant cost savings over time. By reducing defects and ensuring longer service life for pipes, manufacturers can minimize waste and rework, thus enhancing profitability.

5. Compliance with Standards Many industries require adherence to strict standards for surface finish. High-quality polishing machines help manufacturers ensure compliance with these standards, avoiding costly penalties and securing contracts.

Innovations and Future Trends

The steel pipe polishing industry is witnessing several innovative trends. Automation is becoming increasingly integrated into the polishing process, reducing the need for manual intervention and increasing efficiency. Moreover, advancements in materials science are leading to the development of new abrasives that provide better finishes while being eco-friendly.

In conclusion, high-quality steel pipe polishing machines are an indispensable asset in the manufacturing sector. Their ability to produce superior surface finishes, enhance corrosion resistance, and improve overall pipe performance cannot be overstated. As technology continues to evolve, businesses that invest in the latest polishing solutions will likely gain a competitive edge in the market, ensuring they meet the ever-increasing demands for quality and efficiency. The future of steel pipe production is bright, with polishing machines at its forefront, driving innovation and excellence in manufacturing processes.