Exploring the Landscape of GP Centerless Grinder Suppliers

In the world of manufacturing and precision engineering, the role of grinding machines cannot be understated. Among various types of grinders, centerless grinders play a pivotal role, particularly in tasks that require high precision and efficiency. GP Centerless Grinders have emerged as significant contenders in this arena, and understanding the landscape of their suppliers is crucial for businesses aiming to harness the best technology and performance in their operations.

Understanding Centerless Grinding

Before delving into suppliers, it is vital to understand what makes centerless grinding unique. Unlike traditional grinding methods that require the support of fixtures, centerless grinding allows manufacturers to grind parts without any form of additional support. This innovation enhances productivity, reduces downtime, and enables the processing of multiple parts simultaneously. It’s particularly advantageous for cylindrical parts, which are often found in automotive components, aerospace manufacturing, and medical devices.

The Importance of Choosing the Right Supplier

Choosing the right supplier for GP Centerless Grinders not only influences the quality of the machinery but also affects the overall productivity of manufacturing processes. Numerous factors come into play when selecting a supplier, including the technology offered, reliability, customer service, and after-sales support. A good supplier will provide not only high-quality machines but also comprehensive training and assistance in the setup and maintenance of the equipment.

Top Suppliers in the Market

Undoubtedly, the market is flooded with suppliers, each claiming to offer the best technology. Well-known manufacturers such as Glebar Company and Royal Master Grinders have established themselves as leaders in providing high-quality centerless grinding solutions. These companies have focused on innovation, continuously updating their technology to meet the evolving needs of industries.

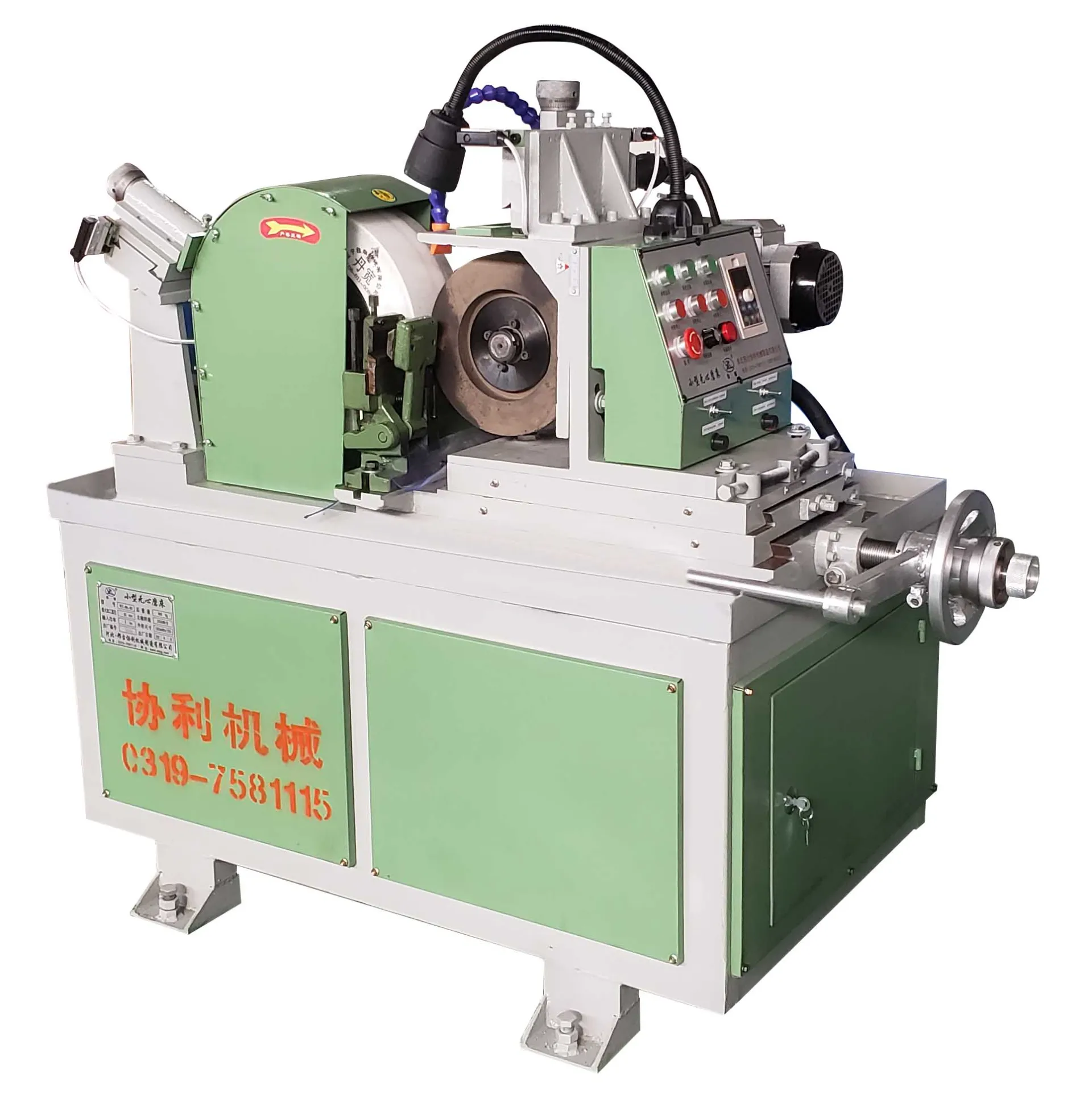

gp centerless grinder suppliers

Glebar, for instance, specializes in designing automation systems that allow for the seamless integration of centerless grinders into existing production lines. This feature is crucial for companies looking to minimize disruptions while upgrading their equipment. Royal Master Grinders, on the other hand, is renowned for its precision and customization capabilities, ensuring that clients receive machines tailored specifically to their operational needs.

Additionally, newer entrants such as Koyo Machinery and Okuma offer competitive alternatives. Koyo is known for its robust machine designs that optimize performance under heavy workloads, while Okuma emphasizes user-friendly interfaces and advanced software controls, making them increasingly popular among manufacturers looking to adopt Industry 4.0 technologies.

Considerations for Investment

Investing in GP Centerless Grinders requires a careful evaluation of both the supplier and the machine. Key considerations include the machine's specifications, historical performance, the potential return on investment, and compatibility with the existing production setup. It’s advisable to engage in product demonstrations and seek reviews from other users to gauge real-world performance.

Furthermore, working with suppliers that offer financing options, extended warranties, and ongoing technical support can alleviate concerns associated with initial investments.

Future Trends in Centerless Grinding

As technology advances, the future of centerless grinding looks promising. Suppliers are increasingly integrating smart technology into their machines, allowing for enhanced monitoring and predictive maintenance capabilities. This development not only extends the life of machines but also ensures consistent operational efficiency.

In conclusion, the choice of a GP Centerless Grinder supplier is a critical decision that impacts overall manufacturing productivity and quality. By assessing reliable suppliers and staying updated on industry trends, businesses can position themselves for success in an increasingly competitive environment.