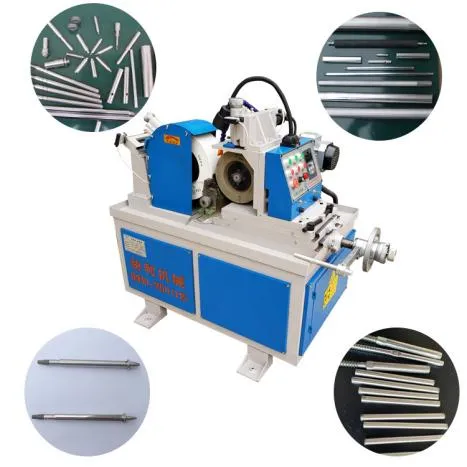

Custom Centerless Grinders for Sale Optimizing Precision in Manufacturing

In the world of manufacturing, precision and efficiency are paramount. One of the most vital tools in achieving these metrics is the centerless grinder. These machines are designed to grind the outer diameter of a workpiece without the need for a spindle, ensuring a smooth and accurate finish. As industries continue to evolve, the demand for custom centerless grinders is on the rise, catering to specific needs and applications. This article explores the advantages of custom centerless grinders for sale and how they can enhance manufacturing processes.

The Importance of Centerless Grinding

Centerless grinding serves a unique purpose in manufacturing. Unlike traditional grinding methods, which require a spindle to hold the workpiece, centerless grinding allows for continuous operation. The workpiece is placed between two wheels a grinding wheel and a regulating wheel. This setup facilitates the grinding of the outer diameter of the workpiece as it moves through the machine. The advantages of this method include reduced operational costs, greater speed, and improved accuracy in producing cylindrical parts.

Why Customization Matters

Not all manufacturing applications are the same. Different industries, ranging from automotive to aerospace, have unique requirements that cannot always be met with off-the-shelf grinding machines. This is where custom centerless grinders come into play. Customization offers the ability to adjust many aspects of the grinder, such as size, power, and features, to meet specific manufacturing needs.

1. Tailored Solutions Custom grinders can be designed to handle specific materials and part sizes, accommodating varying diameters and lengths. This flexibility ensures optimal performance for complex projects, reducing waste and enhancing productivity.

2. Enhanced Efficiency By aligning the machine's capabilities with the manufacturer's needs, custom centerless grinders can significantly reduce downtime. They can be engineered for faster cycle times and higher throughput, leading to more efficient operations.

3. Increased Precision When manufacturing critical components, any deviation from specifications can lead to costly errors. Customized grinders can incorporate advanced technology, such as CNC controls, to enhance accuracy and replicability.

custom centerless grinder for sale

4. Improved Flexibility With customized features, manufacturers can quickly adapt to changing demands and product lines. This flexibility is vital in today’s fast-paced market environment, allowing businesses to respond effectively to new customer requirements.

Finding the Right Custom Centerless Grinder

When searching for custom centerless grinders for sale, manufacturers should consider several factors

- Vendor Reputation It is critical to work with reputable suppliers who have a proven track record in building custom grinding machines. Look for companies that offer comprehensive support, including installation and maintenance services.

- Specifications and Features Assess the technical specifications of the grinder, including spindle speed, wheel size, and control systems. Ensure that the machine can be tailored to your specific needs.

- Budget Considerations While customization can come with a higher upfront cost, consider the long-term savings generated through increased efficiency and reduced material waste. Balancing initial investment against potential returns is essential for making a smart financial decision.

- Customer Support Reliable customer service and technical support can save you time and money in the long run. Choose a supplier that offers continuous support and training for your team.

Conclusion

Investing in custom centerless grinders can significantly enhance productivity and precision in manufacturing. These machines offer tailored solutions that meet the diverse needs of various industries. By focusing on customization, manufacturers can achieve greater efficiency, accuracy, and flexibility in their operations. When searching for custom centerless grinders for sale, it’s crucial to consider vendor reputation, specifications, budget, and customer support. This investment not only optimizes the grinding process but also positions manufacturers for success in an increasingly competitive market. Embrace the power of custom centerless grinders and watch your manufacturing capabilities soar.