The Cincinnati Twin Grip Centerless Grinder A Key Export in Precision Manufacturing

The world of precision manufacturing is a highly competitive arena, where efficiency, accuracy, and reliability are paramount. Among the many tools employed by manufacturers, centerless grinders stand out due to their ability to produce high volumes of precision parts with minimal human intervention. One notable manufacturer in this field is Cincinnati, well-known for its Twin Grip Centerless Grinder. This article delves into the significance of Cincinnati’s Twin Grip Centerless Grinder and its impact on global exports.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods where the part is held in place between two centers, centerless grinding allows parts to be fed continuously through a grinding wheel and a regulating wheel. This setup offers numerous advantages, including increased throughput and reduced labor costs, making it a favored choice in various industries, from automotive to aerospace.

The Cincinnati Twin Grip Centerless Grinder

Cincinnati’s Twin Grip Centerless Grinder is particularly noteworthy for its innovative design and robust performance. This machine features dual wheels that grip the workpiece at two points, ensuring exceptional stability and precision. Such a design minimizes the risk of vibration and allows for tighter tolerances, essential for components used in high-speed and high-stress environments.

The Twin Grip model stands out due to its versatility. It can accommodate a wide range of part sizes and shapes, making it an attractive option for manufacturers looking to optimize their production lines. Moreover, its user-friendly interface and programmable controls enable operators to set up and switch between different jobs with ease, fostering higher productivity levels.

Global Export Trends

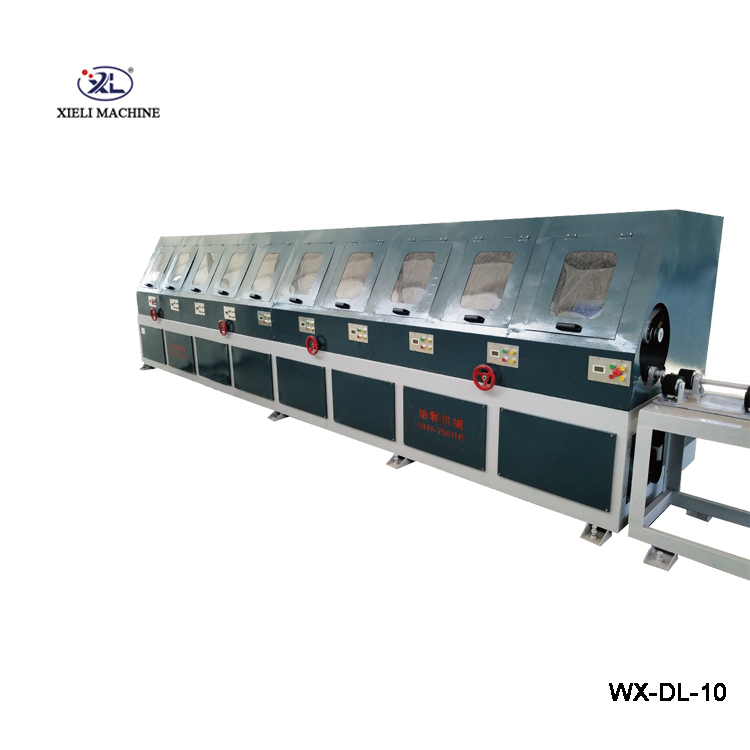

cincinnati twin grip centerless grinder exporters

As the demand for precision machined parts continues to rise, the export market for manufacturing equipment, particularly centerless grinders, is witnessing significant growth. The Cincinnati Twin Grip Centerless Grinder has become a preferred choice for manufacturers worldwide, thanks to its superior performance and reliability. Countries with burgeoning manufacturing sectors, such as India, China, and Brazil, are increasingly investing in advanced machinery like the Cincinnati Twin Grip to enhance their production capabilities.

Exporters of this grinder have also adapted to the growing global market by offering customized solutions

. The capability to modify the machine according to specific customer needs not only enhances the appeal of the Cincinnati Twin Grip but also strengthens brand loyalty among international clients.

Competitive Advantages

Cincinnati's commitment to quality and innovation has solidified its reputation as a leader in the centerless grinding market. The Twin Grip Centerless Grinder benefits from advanced engineering solutions that prioritize both durability and precision. This competitive edge is crucial in an industry where downtime can lead to significant losses.

Furthermore, Cincinnati provides comprehensive support services, including training and maintenance, to its clients worldwide. This ensures that operators can maximize the efficiency of their machines, resulting in better production outcomes.

Conclusion

In summary, the Cincinnati Twin Grip Centerless Grinder is more than just a piece of machinery; it is a vital tool that supports the global manufacturing industry in achieving high precision and efficiency. As international markets continue to expand, the demand for quality grinding solutions will only increase. For exporters, leveraging the capabilities of the Cincinnati Twin Grip not only enhances their product offerings but also positions them as leaders in supplying state-of-the-art equipment to the world's manufacturers.

Investing in technologies like the Cincinnati Twin Grip Centerless Grinder is a testament to a manufacturer’s commitment to excellence and innovation, ensuring they remain competitive in an ever-evolving marketplace. As manufacturing demands grow globally, tools that deliver speed, precision, and reliability will continue to be in high demand, making Cincinnati a key player in shaping the future of precision engineering.