Understanding China Centerless Grinder Parts

Centerless grinding is a specialized form of Abrasive Machining that has gained significant traction in the manufacturing industry, particularly in China. This process involves the grinding of cylindrical parts without the need for a centering device, making it ideal for producing high volumes of small to medium-sized parts with extreme precision. As the demand for centerless grinding increases, so does the need for high-quality centerless grinder parts. This article will delve into the essential components of centerless grinders and highlight the factors to consider when sourcing these parts from China.

What is Centerless Grinding?

Centerless grinding is a technique that allows for the grinding of round workpieces without the use of a spindle to hold the workpiece in place. Instead, the workpiece is supported by a work blade and held between two grinding wheels — a regulating wheel and a grinding wheel. The regulating wheel controls the rotation and linear movement of the workpiece, while the grinding wheel removes material.

This technology has become increasingly popular across various sectors, including automotive, aerospace, and medical device manufacturing. It’s known for producing parts with high dimensional accuracy and surface finish quality.

Key Components of Centerless Grinders

When discussing centerless grinders, several critical parts play a vital role in the grinding process

1. Grinding Wheel This is the primary tool used for material removal. The composition and grit size of the grinding wheel are significant factors that affect the grinding efficiency and finish of the workpiece.

2. Regulating Wheel This wheel regulates the speed and feeding of the workpiece. Choosing the right material and hardness for the regulating wheel is crucial to achieving the desired results.

3. Work Blade The work blade supports the workpiece and is critical for ensuring stability during grinding. The angle and height of the work blade can significantly influence the grinding results.

4. Machine Bed The structural part of the grinder, the machine bed, must be robust enough to handle the vibrations and forces produced during operation.

5. Spindle Assembly The spindle holds the grinding wheels and ensures they remain aligned. Precision in the spindle assembly is vital for maintaining the accuracy of the grinding process.

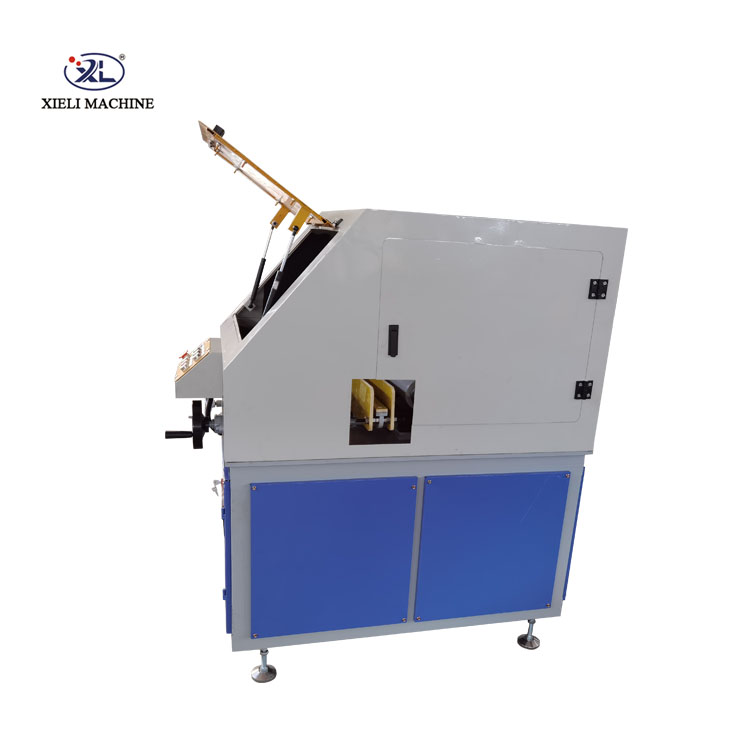

china centerless grinder parts

6. Control Systems Modern centerless grinders are equipped with sophisticated control systems that monitor and regulate the grinding parameters such as speed, feed rate, and pressure.

Sourcing Centerless Grinder Parts from China

As a global manufacturing hub, China has become a significant player in the production of centerless grinder parts. When sourcing these components, manufacturers should consider several factors

1. Quality Assurance The quality of parts is paramount. It’s essential to work with suppliers that have established quality control processes and certifications, such as ISO.

2. Material Specifications Ensure that the parts are made from the correct materials that meet industry standards. Different grinding applications may require specific materials for optimal performance.

3. Customization Some manufacturers may need custom parts to suit unique requirements. It’s beneficial to collaborate with suppliers that offer customization options.

4. Cost-Effectiveness While cost is a significant factor, it should not compromise quality. Finding a balance between price and quality is critical for long-term success.

5. Supplier Reputation Conduct background checks and seek reviews or testimonials from other companies that have sourced parts from potential suppliers. A good reputation is often indicative of reliability and service quality.

6. Lead Time and Logistics Understanding the lead times and logistics involved in acquiring parts from China is crucial for planning production schedules. Efficient supply chain management can significantly impact manufacturing operations.

Conclusion

Centerless grinding plays a vital role in the production of precision components across various industries. Understanding the essential parts of a centerless grinder and the factors to consider when sourcing them from China can enhance manufacturing efficiency and product quality. By investing in high-quality parts and establishing strong supplier relationships, manufacturers can ensure they remain competitive in an increasingly demanding market.