Understanding Centerless OD Grinder Quotations A Guide for Manufacturers

In the realm of precision manufacturing, the centerless outside diameter (OD) grinder plays a vital role in achieving high levels of accuracy and efficiency in the production process. As manufacturers seek to enhance their capabilities, understanding how to interpret quotations for centerless OD grinders becomes crucial. This article will delve into the key components of a centerless OD grinder quotation, providing manufacturers with the necessary insights to make informed decisions.

What is a Centerless OD Grinder?

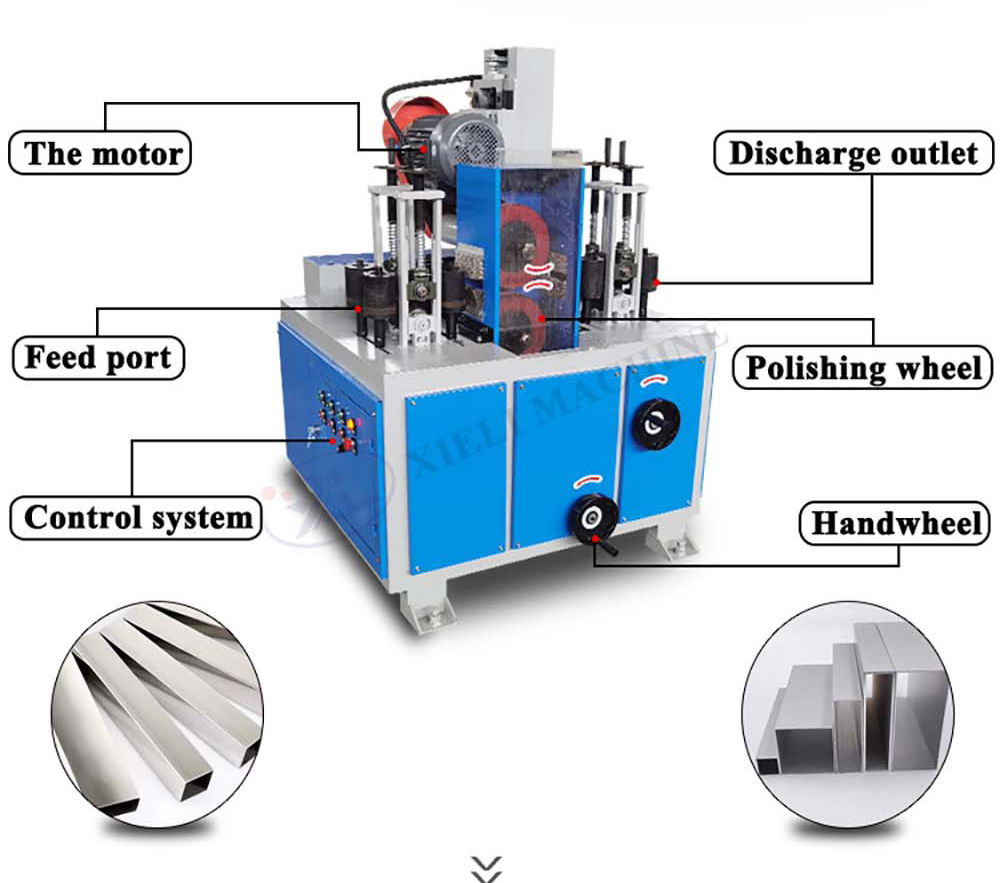

A centerless OD grinder is a machining tool used for shaping and finishing cylindrical parts without the need for a central axis. The part to be ground is held in place between two wheels the grinding wheel and the regulating wheel. This unique configuration allows for continuous rotation and precise control over the dimensions of the workpiece, making it ideal for high volume production of components such as shafts, pins, and various other cylindrical parts.

Key Components of a Quotation

When manufacturers request a quotation for a centerless OD grinder, the provided document typically includes several essential elements

1. Specifications of the Grinder The quotation should detail the technical specifications of the grinder, including its grinding capacity (max diameter and length), type of wheel, RPM (revolutions per minute), and the motor power. It may also indicate the machine's adaptability for various materials, such as steel, aluminum, or brass.

centerless od grinder quotation manufacturer

2. Pricing Structure A transparent pricing structure is fundamental in any quotation. The total cost may comprise several components the base price of the machine, optional accessories such as coolant systems or automation features, and any additional costs like freight or installation. Manufacturers should pay close attention to these details to avoid hidden costs during the procurement process.

3. Lead Time The lead time for delivery is an essential factor in manufacturing operations. The quotation should specify how long it will take to manufacture and deliver the grinder. This timeline is critical for manufacturers to plan their production schedules and manage their inventory effectively.

4. Warranty and Support A comprehensive warranty is a significant advantage when investing in industrial machinery. The quotation should outline the warranty terms, covering parts and labor, and specify the period of protection. Additionally, it should detail the availability of technical support, user training, and custom service agreements.

5. Payment Terms Understanding payment terms is vital in managing cash flow. Quotations typically specify the required deposit, payment schedule, and accepted payment methods. Manufacturers should ensure these terms align with their financial strategies.

6. Technical Documentation A reliable quotation will include a provision for technical documentation, such as operation manuals, maintenance guidelines, and troubleshooting assistance. This documentation is essential for the proper operation and upkeep of the grinder, ensuring a long service life and optimal performance.

Conclusion

In conclusion, a well-structured quotation for a centerless OD grinder encompasses several critical components that manufacturers must carefully evaluate. By understanding the specifications, pricing structure, lead times, warranty and support options, payment terms, and technical documentation included in the quotation, manufacturers can make informed decisions that align with their production needs. Investing in a centerless OD grinder is a strategic move towards enhanced efficiency and quality, and navigating the quoting process effectively lays the groundwork for successful operational improvements. As the demand for precision machining continues to rise, understanding the nuances of these quotations will empower manufacturers to leverage advanced technologies to stay competitive in their respective industries.