Understanding Centerless Grinder Suppliers and Their Pricelists

In the realm of manufacturing and metalworking, precision and efficiency are paramount. One of the essential tools that aid in achieving these attributes is the centerless grinder. Unlike traditional grinders that involve the support of the workpiece, centerless grinders hold the material using two rotary grinding wheels, which allows for continuous operation and higher production rates. As industries seek to enhance their operations, understanding centerless grinder suppliers and their pricelists is critical.

The Role of Centerless Grinders

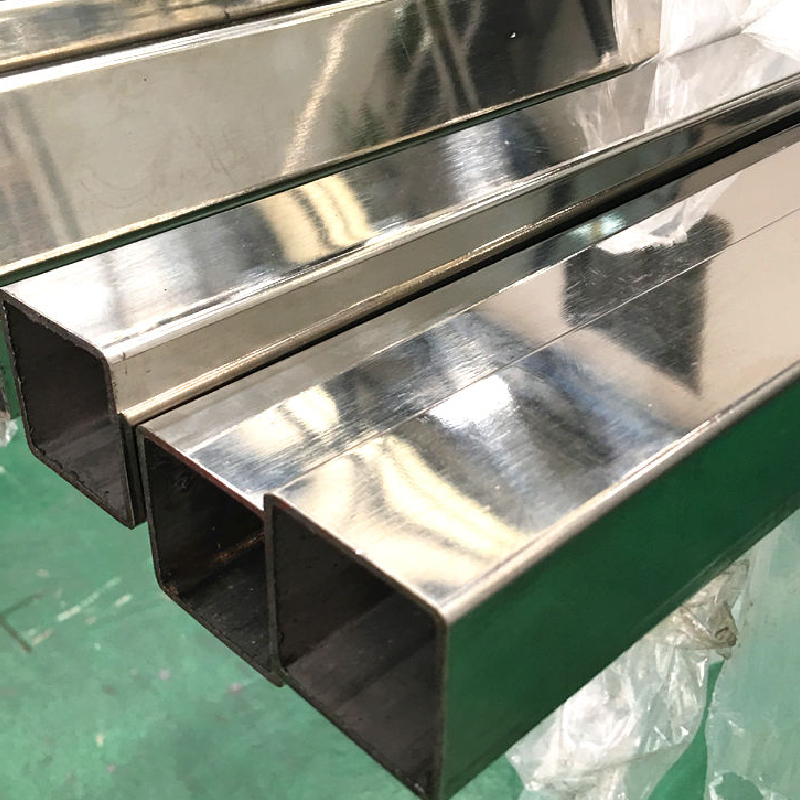

Centerless grinding is particularly useful for producing components with high uniformity and tight tolerances. The common applications include grinding cylindrical parts such as shafts, rods, and tubes. These machines are favorable as they do not require complex setups and enable the grinding of multiple components in a single operation, significantly saving on time and labor costs.

Identifying Reliable Suppliers

When considering investments in centerless grinders, it is essential to choose reliable suppliers. A good supplier not only offers machines that meet industry standards but also provides excellent customer support, maintenance services, and training for operators. Some of the most recognized manufacturers of centerless grinders include Cincinnati Milacron, Royal Master Grinders, and Koyo Machinery, among others.

These suppliers often feature comprehensive catalogs that outline their product offerings and detailed specifications to help buyers make informed decisions. When contacting suppliers, potential customers should inquire about the machines' capabilities, including grinding size, power requirements, and any additional features that enhance versatility and efficiency.

Pricing Factors

The pricing of centerless grinders can vary widely based on several factors, including

centerless grinder suppliers pricelist

1. Machine Type Various types of centerless grinders are available, such as thrufeed, infeed, and grinding machines that accept different shapes and sizes of workpieces. Each type has a different price point. 2. Size and Capacity Larger machines capable of handling heavier workloads naturally come at a premium. Consideration of the intended application and required throughput is crucial in evaluating the necessary investment.

3. Brand Reputation Established brands often command higher prices due to their reputation for quality and durability. However, this may come with added assurance of longevity and performance.

4. Technology and Features Advanced features such as computer numerical control (CNC) capabilities, automatic loading mechanisms, and enhanced safety measures can contribute significantly to the overall cost of the machine. Businesses must balance the cost with the potential for increased productivity and lower operational costs.

5. After-Sales Services Many suppliers bundle their machines with after-sales support, including installation, training, and maintenance. The inclusion of these services may influence the overall pricing.

Getting the Best Deals

To ensure a good return on investment, companies should obtain multiple quotes from different suppliers. This process enables buyers to compare specifications, pricing structures, and value-added services. Some suppliers might offer financing options or discounts for bulk purchases, which can further reduce the initial capital outlay.

It's also beneficial to consider used or refurbished centerless grinders as alternatives. Many suppliers provide certified pre-owned machines that can deliver significant savings while still meeting performance standards.

Conclusion

Investing in a centerless grinder is a decision that can influence the efficiency and productivity of manufacturing operations. By understanding suppliers' offerings and pricing models, businesses can make informed decisions that align with their operational needs and budget constraints. A thorough assessment of machine types, brand reputation, after-sales services, and pricing will ultimately lead to acquiring a centerless grinder that enhances productivity and maintains the quality demands of modern manufacturing. Whether upgrading existing equipment or investing in new technology, each decision will have a profound impact on the precision and efficiency of production processes.