The Importance of Centerless Grinder Suppliers in Manufacturing

In the realm of modern manufacturing and precision engineering, the role of centerless grinders cannot be overstated. These machines are essential in producing highly accurate and finely finished components, particularly in industries such as automotive, aerospace, and medical device manufacturing. However, the effectiveness of these machines heavily relies on the quality and reliability of the suppliers that provide them. This article explores the significance of centerless grinder suppliers and how they contribute to manufacturing success.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from the surface of an object, allowing manufacturers to achieve tight tolerances and a smooth surface finish. Unlike traditional grinding methods, centerless grinding does not require the workpiece to be mounted on a spindle. Instead, it is held in place by a combination of a grinding wheel, a regulating wheel, and a work support blade. This method is particularly advantageous for producing long, cylindrical parts with uniform dimensions.

The Role of Suppliers

Centerless grinder suppliers play a crucial role in the manufacturing ecosystem. They provide not only the machines themselves but also the necessary components and accessories required for optimal performance. The relationship between manufacturers and their suppliers can significantly impact production efficiency, product quality, and overall business success.

1. Quality Assurance A reputable centerless grinder supplier ensures that the machines and parts they provide meet stringent quality standards. This commitment to quality is vital for manufacturers who rely on precision equipment to produce critical components. High-quality grinders lead to lower defect rates, reduced waste, and enhanced overall efficiency in production.

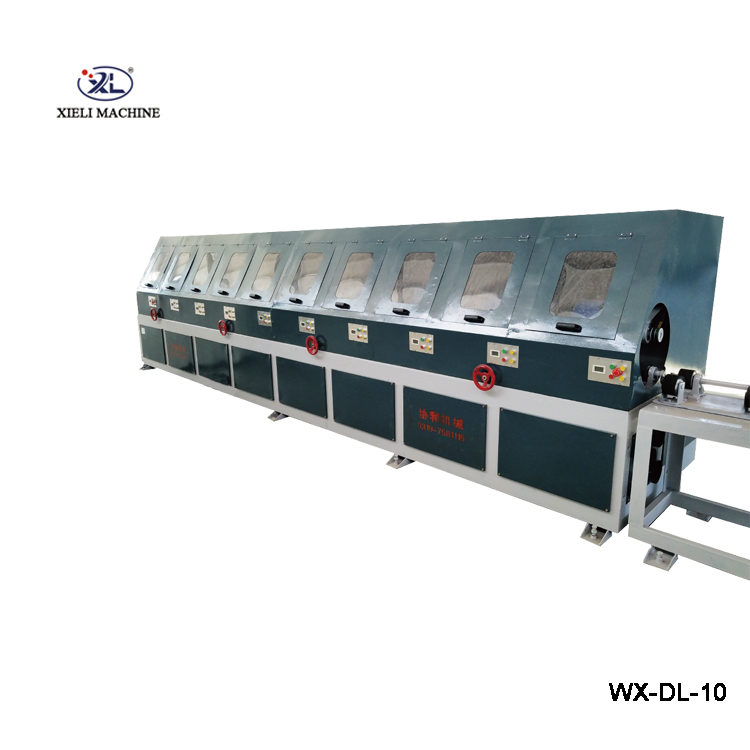

centerless grinder suppliers

2. Technical Support and Expertise Centerless grinder suppliers often offer technical assistance and expertise, which can be invaluable for manufacturers. This support may include installation services, operator training, and maintenance advice. By partnering with knowledgeable suppliers, manufacturers can maximize the capabilities of their grinding machines and troubleshoot any issues that may arise.

3. Customization and Flexibility Different manufacturers have unique needs based on their specific applications and production requirements. Reliable centerless grinder suppliers can provide customization options, ensuring that the machinery fits seamlessly into the manufacturer’s workflow. Whether it’s adjusting the size of the machine or integrating advanced technologies, flexible suppliers can tailor their offerings to meet individual client needs.

4. Innovative Solutions The manufacturing industry is continuously evolving, with new technologies and methodologies emerging regularly. Centerless grinder suppliers that invest in research and development are better positioned to offer innovative solutions, such as automation and advanced control systems. These innovations can significantly enhance productivity and precision, keeping manufacturers competitive in the market.

5. Supply Chain Stability A supplier's ability to maintain a stable supply chain is critical in today's fast-paced manufacturing environment. Manufacturers rely on timely delivery of equipment and components to avoid costly downtime. Suppliers with efficient logistics systems and strong supplier relationships can ensure that manufacturers receive what they need when they need it.

Choosing the Right Supplier

Selecting the right centerless grinder supplier is a decision that should not be taken lightly. Manufacturers should consider factors such as the supplier's reputation, the quality of their products, available support services, and their ability to meet customization needs. Engaging in thorough research, reading customer testimonials, and requesting demonstrations can help manufacturers make informed decisions.

In conclusion, centerless grinder suppliers are vital partners in the manufacturing process. Their quality products, technical expertise, and commitment to innovation enhance productivity and precision. By choosing the right supplier, manufacturers can ensure that they have the tools they need to succeed in an increasingly competitive landscape.