Understanding Centerless Grinder Blades Manufacturers

In the world of precision machining, centerless grinding plays a crucial role in manufacturing metal components that require tight tolerances and a smooth finish. At the heart of this process are centerless grinder blades, specialized tools designed to enhance the efficiency and effectiveness of grinding operations. This article delves into the significance of centerless grinder blades, the factors to consider when selecting a manufacturer, and the trends shaping this industry.

The Role of Centerless Grinder Blades

Centerless grinding is a method that allows for the continuous grinding of workpieces without the need for centering them before the process begins. This offers several advantages, including higher production rates and the ability to grind multiple parts simultaneously. The blades used in these systems are pivotal, as they dictate the type of finish, precision, and overall quality of the ground parts. They come in various shapes and sizes, each tailored for specific applications, such as cylindrical grinding, infeed grinding, or through-feed grinding.

Factors to Consider When Selecting a Manufacturer

1. Quality of Materials A reliable manufacturer should produce blades from high-quality materials. The composition of the grinding wheel significantly influences its performance, durability, and ability to maintain sharpness. Manufacturers using advanced metallurgical processes to develop harder and tougher materials will likely provide a superior product.

2. Expertise and Experience The experience of a manufacturer in the industry can be a good indicator of the quality of their products. Companies with a long track record often have refined their processes over time and possess the technical expertise necessary to answer unique customer needs.

3. Customization Options Every machining environment is different, and the ability to customize blades can be a game-changer. Manufacturers that offer bespoke solutions, such as custom sizes or specialized surface treatments, can provide significant value to their customers by ensuring optimal performance in various applications.

centerless grinder blades manufacturers

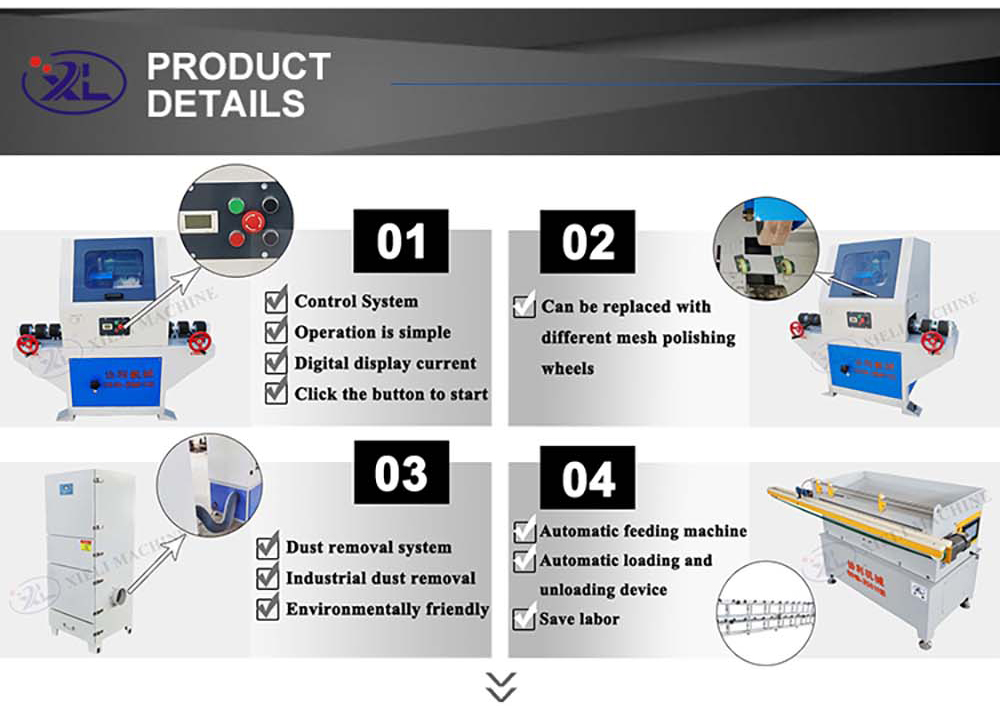

4. Technological Capabilities Advanced manufacturing techniques, including CNC machining and automation, can enhance precision and efficiency in blade production. Companies that invest in current technology are likely to deliver more consistent products and reduce turnaround times for larger orders.

5. Customer Support and Service An essential aspect often overlooked is the level of customer service and technical support offered by a manufacturer. Strong support can assist in troubleshooting, maintenance tips, and advice on optimizing usage, making the relationship with the manufacturer even more valuable.

Emerging Trends in the Industry

The manufacturers of centerless grinder blades are experiencing several emerging trends that are transforming the industry. One notable trend is the increasing demand for automation in manufacturing processes. As industries seek to improve efficiency and reduce labor costs, manufacturers are innovating their production techniques to align with these goals.

Another significant trend is the growing focus on sustainability and environmental responsibility. Many manufacturers are exploring eco-friendly materials and processes, reducing waste, and minimizing their carbon footprint. This shift not only helps the environment but also meets increasing consumer demand for responsible manufacturing practices.

Lastly, technological advancements such as Industry 4.0 are beginning to influence the production of centerless grinder blades. The integration of smart technology allows for better monitoring of the grinding process and predictive maintenance of machinery, leading to enhanced productivity and reduced downtime.

Conclusion

Centerless grinder blades are essential components in the machining industry, directly impacting the quality and efficiency of the grinding process. When choosing a manufacturer, factors like material quality, experience, customization, technological capability, and customer support are crucial. With emerging trends steering the industry toward automation, sustainability, and smart technologies, manufacturers are poised not only to meet current demands but also to adapt to future challenges. As the need for precision and efficiency continues to rise, the role of centerless grinder blades will remain vital in shaping the landscape of metalworking and manufacturing.