CE Certification for Automatic Pipe Polishing Machines Ensuring Quality and Safety

In recent years, the manufacturing sector has witnessed significant advancements in technology, particularly in the field of automation. Among these innovations, automatic pipe polishing machines have emerged as essential tools for manufacturers producing metal pipes and tubes. Notably, the CE (Conformité Européenne) certification stands as a pivotal standard for ensuring the quality and safety of these machines within the European market.

The Importance of CE Certification

CE certification is a mandatory conformity mark for products sold within the European Economic Area (EEA). It indicates that a product meets EU safety, health, and environmental protection requirements. For automatic pipe polishing machines, obtaining CE certification is crucial for several reasons

1. Legal Compliance Manufacturers seeking to market their automatic pipe polishing machines in Europe must comply with CE marking regulations. Non-compliance can result in hefty fines and the prohibition of product sales in the EU market.

2. Consumer Safety The certification process ensures that machines meet rigorous safety standards, thereby protecting end-users from potential hazards associated with machine operation. This includes risks of mechanical failures, electrical issues, and ergonomic concerns.

3. Market Access CE certification facilitates smoother access to the European market. Customers and distributors are more likely to purchase certified machines, knowing they adhere to the highest standards of quality and safety. This can enhance a manufacturer's reputation and foster trust among consumers.

4. Quality Assurance The certification process often involves thorough testing and assessment of the machine's design, manufacturing process, and performance. This assures customers that the automatic pipe polishing machine will deliver consistent results and meet their operational needs.

Features of Automatic Pipe Polishing Machines

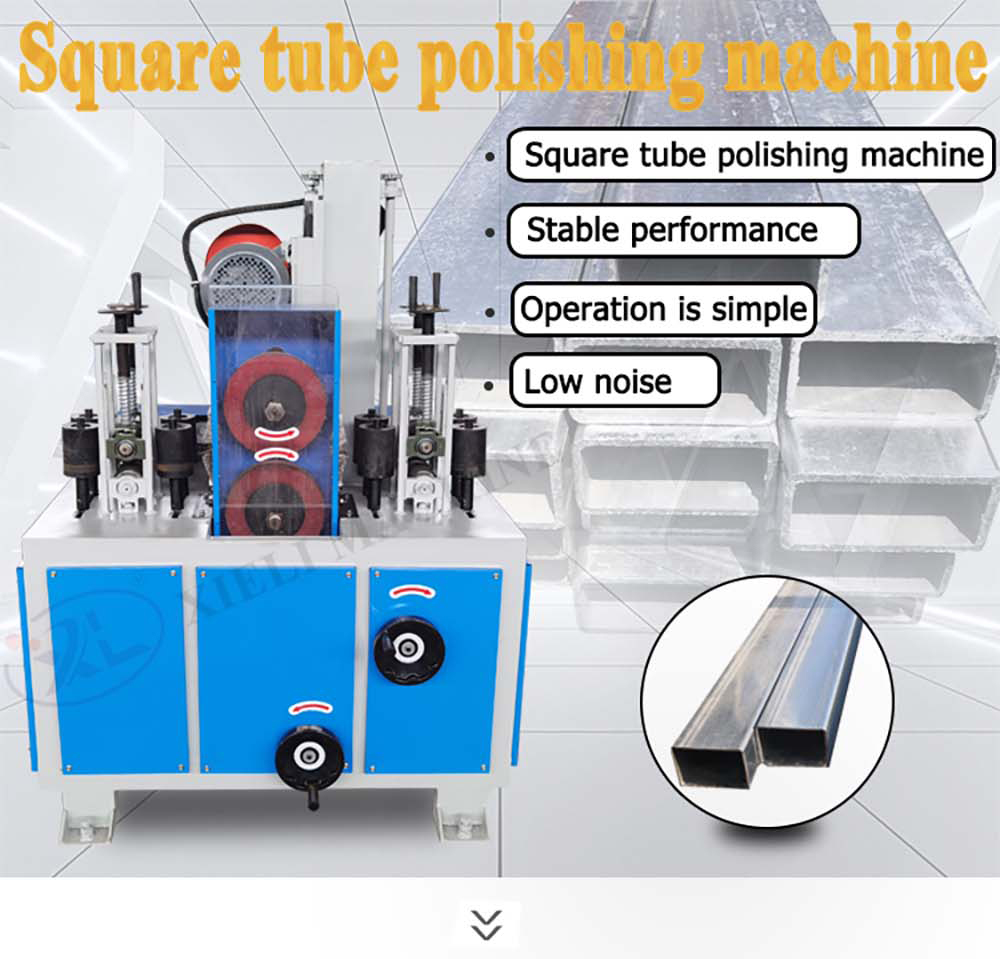

Automatic pipe polishing machines are designed to improve the efficiency and quality of the metal finishing process. They enhance the aesthetic appeal of pipes while also ensuring surface smoothness and removing any imperfections. Key features typically include

- Automated Operations These machines often utilize advanced technology that allows for fully automated polishing processes. This reduces labor costs and minimizes human error.

- Versatility They can accommodate various pipe diameters and materials, including stainless steel, aluminum, and copper, making them ideal for different industries such as automotive, construction, and manufacturing.

ce certification automatic pipe polishing machine

- Adjustable Speed and Pressure Operators can customize the polishing speed and pressure depending on the material and desired finish, allowing for enhanced quality control.

- User-friendly Interfaces Most modern machines come equipped with digital displays and intuitive controls, making it easier for operators to monitor and adjust settings accordingly.

The CE Certification Process

To achieve CE certification for an automatic pipe polishing machine, manufacturers must follow a systematic process that includes

1. Risk Assessment Evaluating potential hazards associated with the machine's operation, including mechanical, electrical, and thermal risks.

2. Compliance with Directives Ensuring that the machine conforms to relevant EU directives, such as the Machinery Directive and the Low Voltage Directive.

3. Testing and Documentation Conducting rigorous testing to confirm compliance and compiling comprehensive documentation detailing the machine's design, specifications, and operating instructions.

4. Notified Body Involvement Depending on the machine's complexity, a manufacturer may need to involve a notified body—an organization authorized to assess conformity to CE requirements.

5. Affixing the CE Mark Once all requirements are met, the manufacturer can affix the CE mark to the machine, signaling its compliance with EU standards.

Conclusion

In conclusion, the CE certification for automatic pipe polishing machines serves as a vital component for manufacturers aiming to enter the European market. It not only ensures compliance with legal standards but also enhances consumer safety and confidence. As the demand for high-quality metal finishing processes continues to rise, the significance of CE-certified automatic pipe polishing machines will undoubtedly grow, leading to improved product quality and operational efficiency within various industries. For manufacturers, investing in the certification process is not just a regulatory requirement—it's a commitment to quality and safety that will pay dividends in the long run.