The Benefits of Buying a CNC Centerless Grinder Machine

In the modern manufacturing landscape, precision and efficiency are crucial factors that determine the success of any production facility. One piece of equipment that stands out for its ability to enhance precision and speed in machining processes is the CNC (Computer Numerical Control) centerless grinder machine. This advanced technology has revolutionized grinding processes across various industries, making it a worthwhile investment for businesses looking to improve their operational capabilities. If you are considering the prospect of buying a CNC centerless grinder machine, here are several benefits that could influence your decision.

Increased Precision

CNC centerless grinders are engineered to deliver unparalleled precision in machining operations. Unlike traditional grinders that rely heavily on manual operation, a CNC machine utilizes sophisticated software to dictate the grinding process. This automation ensures that each part is ground uniformly to the exact specifications required, minimizing human error and enhancing the dimensional accuracy of the final product. For industries that demand high precision, such as aerospace and automotive, investing in a CNC centerless grinder is not merely an option; it is a necessity.

Improved Efficiency

Efficiency is a key driver of productivity in any manufacturing operation. CNC centerless grinders can handle multiple tasks quickly and effectively, significantly reducing processing time. The automatic feeding and grinding capabilities allow for uninterrupted operation, enabling manufacturers to produce larger quantities of parts without a decrease in quality. Furthermore, the integration of automation reduces the need for labor-intensive setups and adjustments, streamlining the production process and optimizing resource utilization.

Versatility in Applications

The versatility of CNC centerless grinder machines enables them to be applicable in a wide range of industries. They can effectively grind cylindrical parts made from various materials, including metals, plastics, and ceramics. Whether you need to process round bars, shafts, or other precision components, a CNC centerless grinder can adapt to your requirements. This flexibility allows companies to expand their product offerings without the need for substantial additional investments in equipment.

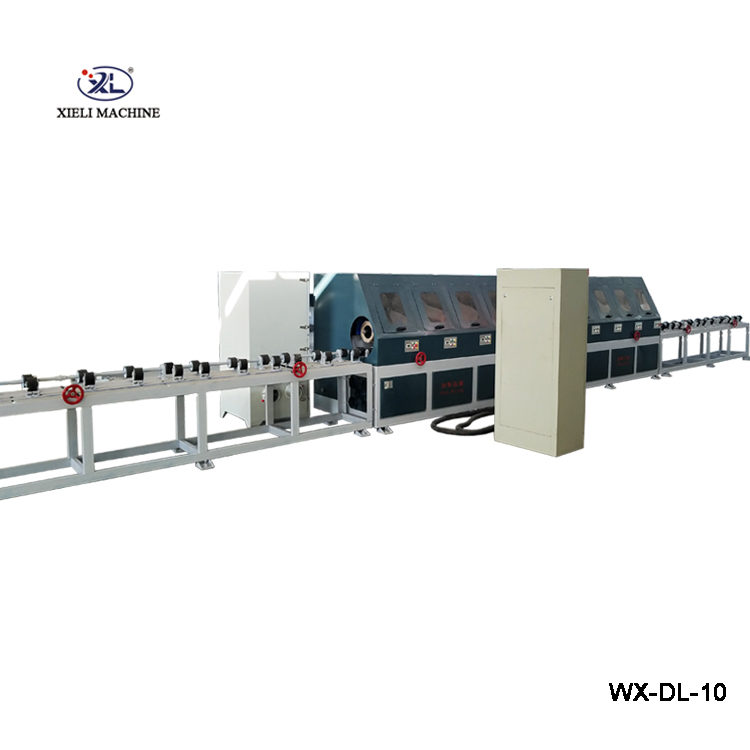

buy cnc centerless grinder machine

Enhanced Surface Quality

Another compelling reason to consider acquiring a CNC centerless grinder machine is the superior surface finish it can achieve. The precision grinding process provides a smoother surface finish compared to conventional grinding methods. This characteristic is critically important in applications where surface integrity impacts performance, such as hydraulic cylinders and precision instruments. A better surface quality not only improves functionality but also boosts the aesthetic appeal of the finished products, which can be a significant advantage in the market.

Reliability and Longevity

When purchasing machinery, the long-term reliability and durability of the equipment are essential factors to consider. CNC centerless grinders are designed with robust construction and high-quality materials that ensure their longevity in demanding environments. Moreover, CNC machines generally require less maintenance compared to their manual counterparts, further reducing operational costs over time. By investing in a quality CNC grinder, businesses can expect to maximize the lifespan of their equipment and reduce the frequency of replacements.

Cost-Effectiveness

Though the initial investment in a CNC centerless grinder machine may seem daunting, it is essential to consider the long-term savings it facilitates. The increase in efficiency, precision, and surface quality directly translates to reduced waste and rework rates, ultimately lowering overall production costs. Combined with the reliable performance and decreased downtime for maintenance, these machines can offer substantial returns on investment for businesses looking to enhance their operations.

Conclusion

In conclusion, buying a CNC centerless grinder machine represents a strategic move for any manufacturing firm aiming to enhance their productivity and quality. With increased precision, improved efficiency, versatility, enhanced surface quality, and long-term reliability, the benefits of investing in such technology are undeniable. As industries continue to evolve, those equipped with advanced machinery like CNC centerless grinders will undoubtedly maintain a competitive edge in the marketplace. For companies looking to keep pace with modern manufacturing demands, a CNC centerless grinder is not just an addition; it’s a critical component of their success.