The Best GP Centerless Grinders Precision and Efficiency at Their Best

In the world of manufacturing and precision engineering, the importance of high-quality machinery cannot be overstated. Among the various types of equipment that contribute to the success of metalwork and machining processes, centerless grinders stand out for their ability to deliver exceptional results in terms of smoothness and dimensional accuracy. This article explores the best General Purpose (GP) centerless grinders, highlighting their essential features, benefits, and applications.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from the surface of a workpiece. Unlike traditional grinding methods, centerless grinding does not require the workpiece to be held in a fixed position. Instead, it is supported between two wheels – the grinding wheel and the regulating wheel – allowing for continuous and efficient operation. This method is particularly advantageous for cylindrical parts, where precision and smooth finishes are crucial.

Key Features of the Best GP Centerless Grinders

1. Robust Construction The best GP centerless grinders are built with a solid foundation to minimize vibrations. This stability ensures consistent performance and extends the lifespan of the machine. High-quality materials and advanced engineering contribute to the durability of these grinders, making them reliable workhorses in manufacturing settings.

2. Precision Engineering Accuracy is paramount in the grinding process. High-end centerless grinders are equipped with advanced control systems that allow for fine adjustments in grinding parameters. This ensures that each component is machined to the desired specifications, adhering to strict industry standards.

3. Versatile Applications GP centerless grinders are designed to handle a wide variety of materials and dimensions. They can work on both small and large workpieces, making them suitable for different industries, including automotive, aerospace, and medical device manufacturing.

4. User-Friendly Operation Modern centerless grinders are designed with the operator in mind. Intuitive controls, digital readouts, and programmable settings allow for easy operation, reducing the learning curve for new users. This leads to increased productivity as operators can quickly set up and adjust the machines for different projects.

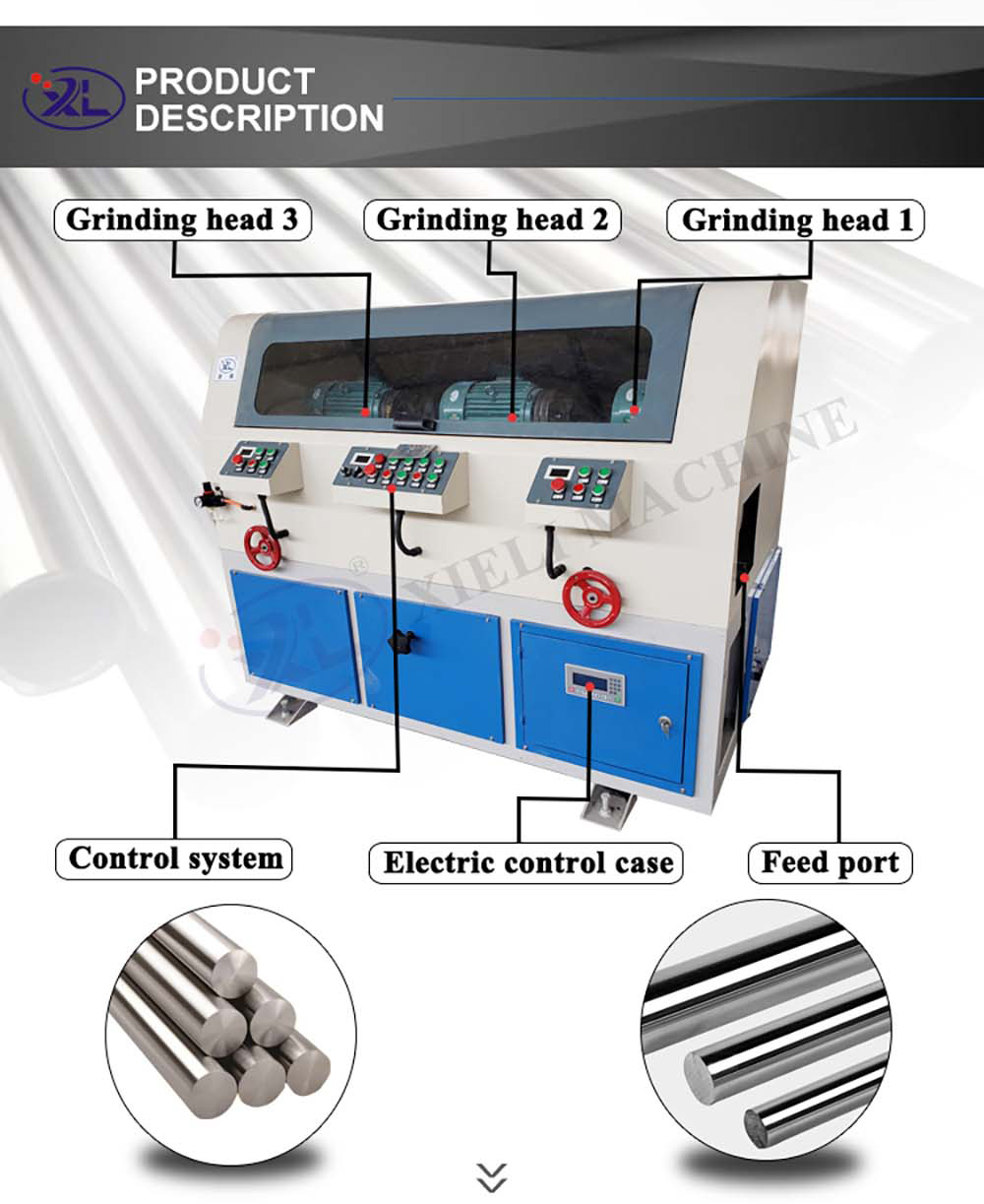

best gp centerless grinder

5. Energy Efficiency With the growing focus on sustainability and energy conservation, the best GP centerless grinders incorporate features that minimize energy consumption without compromising performance. This not only reduces operational costs but also lessens the environmental impact of manufacturing processes.

Benefits of Using Centerless Grinders

1. Increased Production Rates The continuous grinding process allows for faster production cycles. Since there is no need for manual loading and unloading of workpieces, manufacturers can achieve higher output rates with fewer labor costs.

2. Consistency in Quality With advanced technology and precise settings, GP centerless grinders maintain a consistent level of quality across all produced items. This uniformity is essential for industries where tolerances are tight and quality assurance is paramount.

3. Reduced Material Waste The efficient material removal process of centerless grinding minimizes wastage. This not only saves costs but also aligns with efforts to adopt lean manufacturing practices.

4. Improved Surface Finish One of the standout advantages of centerless grinding is its ability to achieve superior surface finishes. This is particularly important for components that will undergo further processing or assembly, where surface quality can impact performance.

Conclusion

Investing in a high-quality GP centerless grinder can be a game-changer for manufacturers looking to enhance precision, efficiency, and quality in their operations. With their robust construction, precision engineering, and user-friendly features, these machines are indispensable tools for producing cylindrical parts across various industries. As manufacturers continue to seek ways to improve their processes, GP centerless grinders will undoubtedly play a vital role in achieving operational excellence, driving innovation, and maintaining competitiveness in a rapidly evolving market. Whether you are a small workshop or a large manufacturing facility, choosing the right centerless grinder can significantly impact your productivity and quality outcomes.