Understanding Centerless Grinder Tables An Essential Element in Precision Machining

In the realm of precision machining, the centerless grinder is a pivotal piece of equipment, particularly known for its ability to create cylindrical components with high accuracy and efficiency. While the focus often rests on the grinding mechanism itself, one cannot overlook the integral role of the centerless grinder table. This article delves into the significance, design, and operational principles of centerless grinder tables, underscoring their essential contributions to the grinding process.

The Basics of Centerless Grinding

Before exploring the specifics of grinder tables, it's crucial to understand the basics of centerless grinding. Unlike traditional grinding, where the workpiece is supported from both ends, centerless grinding uses two main wheels for processing. The workpiece is placed between a grinding wheel and a regulating wheel, allowing it to be ground without any support. This method offers significant advantages, including the ability to achieve ultra-thin tolerances and high production rates.

The Role of the Grinder Table

The centerless grinder table serves as the foundation for this operation. It provides stability and support for the grinding apparatus, ensuring that both the grinding and regulating wheels maintain precise alignment. A well-designed table minimizes vibration and movement, which can adversely affect the accuracy of the grinding process. The table’s configuration is crucial, influencing the machine's overall performance and efficiency.

Design Considerations

When designing a centerless grinder table, several factors must be taken into consideration

1. Material Selection The material of the table should be robust and capable of absorbing vibrations. Common materials include rigid cast iron or steel, which offer the necessary stability and durability.

2. Shape and Size The dimensions of the grinder table must accommodate the specific grinding operation. A larger table can support heavier workpieces, while a smaller, more compact table might be used for precision machining of lighter components.

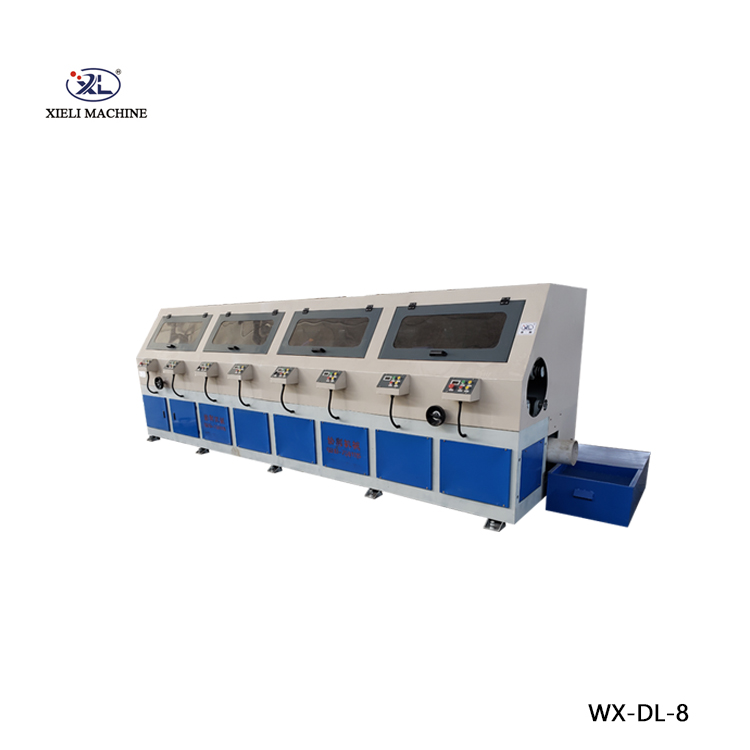

centerless grinder tables product

3. Surface Finish The top surface of the table should be smooth and flat to ensure that there is no impediment to the grinding process. Any imperfections can lead to inaccuracies in the machined parts.

4. Alignment Features Many centerless grinder tables come equipped with alignment features to ensure that both grinding wheels are positioned correctly. This includes adjustable mounts and leveling feet, which enable precise calibration.

5. Mounting Options The table design should allow for easy mounting of additional attachments or accessories, such as work rests or automated feed systems, to enhance the versatility of the grinding setup.

Operational Principles

The effectiveness of a centerless grinder table goes beyond its design. It plays a vital role during operation. As the grinding wheel rotates at high speeds, the regulating wheel helps in controlling the speed and position of the workpiece. The table must ensure that these wheels remain perfectly aligned; any slight deviation can lead to uneven wear or inaccuracies in the finished part.

Moreover, the table must also accommodate the feeding mechanism, which can vary from manual to automatic systems. In advanced setups, the introduction of CNC (Computer Numerical Control) technology further boosts precision, allowing for detailed programming of the grinding parameters.

Maintenance and Care

To ensure longevity and performance, regular maintenance of the grinder table is essential. Operators should routinely check for wear and tear and ensure that the surfaces are clean and free from debris. Proper lubrication of moving parts also helps to maintain operational smoothness.

Conclusion

In conclusion, the centerless grinder table is a critical component that serves many functions in the grinding process. Its design and maintenance significantly impact the machine's performance, and ultimately, the quality of the finished product. As industries continue to demand higher precision and efficiency, the importance of investing in a high-quality centerless grinding setup—including a robust and reliable grinder table—cannot be overstated. By understanding and optimizing this essential element, manufacturers can enhance their operations, reduce waste, and achieve better outcomes in their precision machining tasks.