Understanding Centreless Grinding Machine Prices

Centreless grinding is a crucial process widely used in manufacturing to shape and finish metal parts, ensuring precision and efficiency. This technique eliminates the need for a central fixture, allowing parts to be supported and shaped from the outside, thereby enhancing productivity and reducing handling time. As businesses look to invest in centreless grinding machines, understanding the factors influencing their prices becomes essential.

Several variables impact the pricing of centreless grinding machines. First and foremost, the type of machine plays a significant role. There are two main types of centreless grinding machines infeed and through-feed grinders. Infeed grinders are designed for processing complex shapes and profiles, while through-feed grinders are more suited for simpler, cylindrical parts. The complexity and specialization of a machine typically drive up its cost.

Secondly, the manufacturer’s brand reputation and the machine’s build quality significantly influence pricing. Renowned manufacturers often charge a premium for their machines due to their reliability, advanced technology, and after-sales support. These investments can pay off in the long run through reduced maintenance costs and increased operational efficiency.

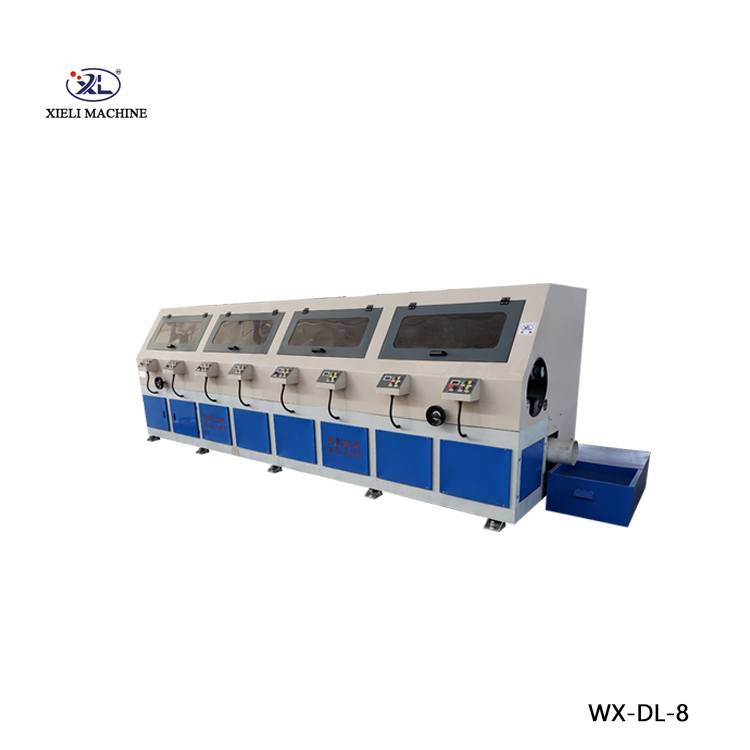

centreless grinding machine price

Additionally, the machine's features contribute to its price. Advanced centreless grinders may come equipped with CNC (Computer Numerical Control) capabilities, automation features, and enhanced safety systems. While these features increase the initial investment, they can also lead to higher production rates and better precision, which may justify the cost for many businesses.

Moreover, market conditions play a crucial role in determining the price of centreless grinding machines. Fluctuations in raw material costs, supply chain dynamics, and demand in the manufacturing sector can influence machine prices. In recent years, there has been a noticeable increase in demand for precision grinding machines due to advancements in automotive, aerospace, and medical device manufacturing sectors, which can drive prices upward.

When considering the purchase of a centreless grinding machine, prospective buyers should also evaluate total cost of ownership. This includes not only the initial purchase price but also ongoing costs such as maintenance, tooling, and operational efficiency. Investing in a higher-quality machine may result in lower operating costs and longer lifespan, leading to savings over time.

In conclusion, centreless grinding machine prices can vary widely based on a range of factors, including the machine type, brand reputation, features, and market dynamics. For businesses looking to be competitive, investing in a high-quality centreless grinding machine is crucial. Understanding these price determinants helps companies make informed purchasing decisions that align with their production needs and budget constraints. As manufacturing processes continue to evolve, investing in the right machinery today can pave the way for enhanced productivity and profitability in the future.