High Quality OSHA Centerless Grinder Ensuring Safety and Precision in Precision Engineering

In the world of precision engineering, achieving the highest level of accuracy and efficiency in manufacturing is paramount. Among the tools that facilitate this precision is the centerless grinder. This machine plays a critical role in shaping and finishing components used in various industries, from automotive to aerospace. However, the introduction of stringent safety standards by the Occupational Safety and Health Administration (OSHA) ensures that while precision is achieved, worker safety is not compromised. This article delves into the importance of high-quality OSHA-compliant centerless grinders and their crucial role in modern manufacturing.

Understanding Centerless Grinding

Centerless grinding is a machining process utilized for producing precise cylindrical shapes. Unlike conventional grinding methods, where the workpiece is held between two centers, centerless grinding supports the workpiece on a work rest blade and utilizes a regulating wheel to drive the workpiece. This unique arrangement allows for continuous operation, maximizes efficiency, and minimizes defects, making it an ideal choice for high-volume production runs.

The Importance of Quality

The performance of a centerless grinder is significantly influenced by its design, components, and overall build quality. High-quality grinders exhibit precision in dimensions, tolerance control, and dependable performance. When investing in centerless grinders, manufacturers must prioritize machines that adhere to OSHA standards, as these regulations facilitate a safe working environment while ensuring the machinery operates at peak efficiency.

OSHA Compliance and Safety Features

OSHA plays a pivotal role in setting forth safety standards that all manufacturing equipment, including centerless grinders, must meet. Compliance with OSHA regulations is essential not only for ensuring employee safety but also for maintaining operational continuity. Key safety features that high-quality OSHA-compliant centerless grinders incorporate include

1. Emergency Stop Buttons Essential for ensuring quick shutdowns in the event of an emergency, these buttons are strategically placed around the machine for easy accessibility.

2. Guards and Shields Proper shielding around moving parts prevents accidental contact, thereby reducing the risk of injuries to operators.

3. Training and Documentation OSHA emphasizes the importance of training workers on safe operating procedures. High-quality manufacturers often provide comprehensive training manuals and schedules that instruct operators on safe practices.

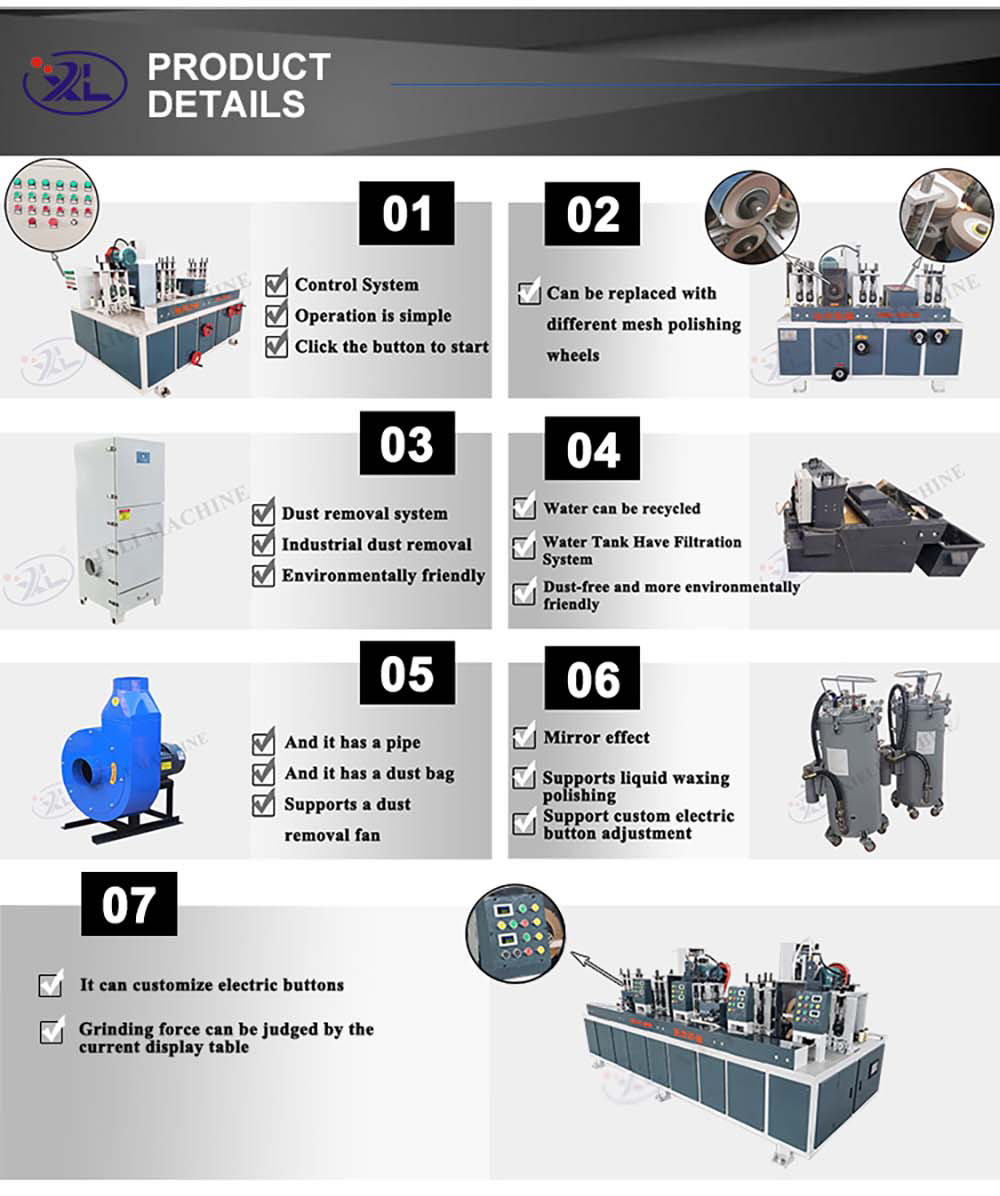

high quality osha centerless grinder

5. Regular Maintenance Standards Compliance with OSHA encourages the implementation of routine maintenance procedures to ensure the machinery remains in optimal working condition. Regular check-ups help in early detection of wear and tear, thus preventing accidents.

The Benefits of High-Quality Centerless Grinders

Investing in high-quality, OSHA-compliant centerless grinders yields several advantages

1. Increased Productivity High-quality grinders deliver consistent performance, reducing downtime and increasing output.

2. Improved Safety OSHA-compliance ensures that machinery operates safely, protecting workers from potential hazards and promoting a culture of safety within the workplace.

3. Enhanced Precision Quality grinders boast superior design features that enhance the precision and quality of the finished product, often meeting or exceeding industry standards.

4. Cost-Effectiveness While high-quality equipment may require a larger initial investment, the durability and reliability of these machines often translate to lower long-term operational costs.

5. Regulatory Compliance Ensuring that centerless grinders meet OSHA standards helps businesses avoid legal penalties and enhances their reputation for sustainability and responsibility.

Conclusion

High-quality OSHA-compliant centerless grinders are an essential asset for any precision engineering facility. They not only enhance operational efficiency but also create a safe working environment that complies with essential safety regulations. As manufacturers strive for greater precision and productivity, investing in such quality equipment becomes an invaluable aspect of modern manufacturing strategies. Emphasizing both safety and technological advancements will ultimately lead to superior machinery, safer workplaces, and heightened productivity.