Understanding OSHA Standards in Centerless Grinding A Guide for Manufacturers

Centerless grinding is an essential manufacturing process used to produce precision cylindrical parts. The method is characterized by its ability to grind parts efficiently without the need for any additional setup or fixtures, making it a popular choice in various industries. However, like any machinery, centerless grinders that are used in manufacturing must adhere to safety regulations to protect workers and ensure a safe working environment. This is where the Occupational Safety and Health Administration (OSHA) comes into play.

What is Centerless Grinding?

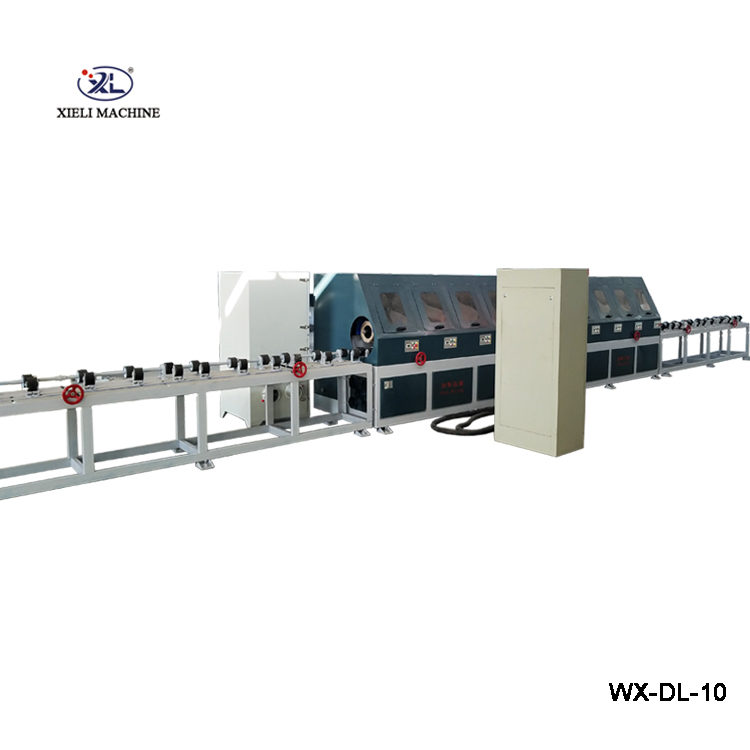

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike conventional grinding, where the workpiece is held in place by a fixture, in centerless grinding, the workpiece is supported by an upper grinding wheel and a lower regulating wheel. This unique setup allows for high-speed precision grinding, making it ideal for producing precision parts in large volumes.

Importance of OSHA Compliance

OSHA was created to ensure safe and healthful working conditions for employees across various industries, including manufacturing. Centerless grinders pose certain hazards that could lead to serious injuries if proper safety measures are not implemented. Compliance with OSHA standards is therefore crucial for manufacturers using centerless grinding machines.

Common Hazards Associated with Centerless Grinding

1. Entanglement Risks Moving parts of the grinding machine can pose entanglement hazards. Workers may unintentionally come into contact with the moving components, leading to severe injuries.

2. Noise Exposure Centerless grinding machines can produce high levels of noise, which can lead to hearing loss over time. OSHA has stipulated regulations regarding permissible noise levels in the workplace to protect workers.

3. Dust and Particulate Matter The grinding process generates dust and other particulate matter, which can cause respiratory issues if inhaled. OSHA standards require appropriate ventilation systems and personal protective equipment (PPE) to mitigate exposure.

4. Vibration Prolonged exposure to vibrating tools can lead to hand-arm vibration syndrome (HAVS). Manufacturers must ensure that operators take regular breaks and use tools that minimize vibration.

OSHA Regulations Relevant to Centerless Grinding

To ensure safety when using centerless grinders, manufacturers must comply with specific OSHA regulations, such as

osha centerless grinder manufacturer

- Machine Guarding (OSHA Standard 1910.212) All machines, including centerless grinders, must be equipped with proper guarding to prevent accidental contact with moving parts.

- Noise Exposure (OSHA Standard 1910.95) Employers are required to monitor noise levels in the workplace and implement a hearing conservation program if exposure exceeds permissible limits.

- Respiratory Protection (OSHA Standard 1910.134) Workers exposed to harmful dust generated during the grinding process must be provided with appropriate respiratory protection.

- Personal Protective Equipment (PPE) (OSHA Standard 1910.132) Employees must be equipped with PPE like safety glasses, gloves, and hearing protection to minimize the risk of injuries.

Best Practices for Manufacturers

To promote a culture of safety and enhance compliance with OSHA regulations, manufacturers can implement the following best practices

1. Training and Awareness Programs Provide comprehensive training to operators regarding the safe operation of centerless grinders and the importance of adhering to OSHA standards.

2. Regular Maintenance and Inspection Conduct routine inspections and maintenance on grinding machines to identify potential hazards and ensure that safety guards are in place and functioning correctly.

3. Ergonomic Workstation Design Design workstations to reduce strain on operators and promote ergonomic practices, which can minimize the risk of repetitive strain injuries.

4. Establishing Safety Protocols Develop and enforce written safety protocols that include emergency procedures and equipment handling guidelines.

Conclusion

Ensuring compliance with OSHA standards is paramount for manufacturers who utilize centerless grinding processes. By understanding the hazards associated with these machines and implementing the necessary safety measures, manufacturers can protect their workers and enhance overall productivity. A commitment to safety not only fosters a positive work environment but also enhances the reputation of the manufacturing entity in the industry. By prioritizing OSHA guidelines, manufacturers can achieve operational excellence while safeguarding their most valuable asset their employees.