Tube Polishing Machine Services in India Enhancing Quality and Efficiency

In the world of manufacturing, the importance of surface finishing cannot be overstated. Especially in industries like automotive, aerospace, and food processing, the quality of metal surfaces can significantly influence overall product performance, durability, and aesthetic appeal. Among the various solutions available for achieving high-quality finishes, tube polishing machines have emerged as essential equipment. In India, the demand for tube polishing machine services is steadily increasing, driven by the need for precision and efficiency in manufacturing processes.

Understanding Tube Polishing Machines

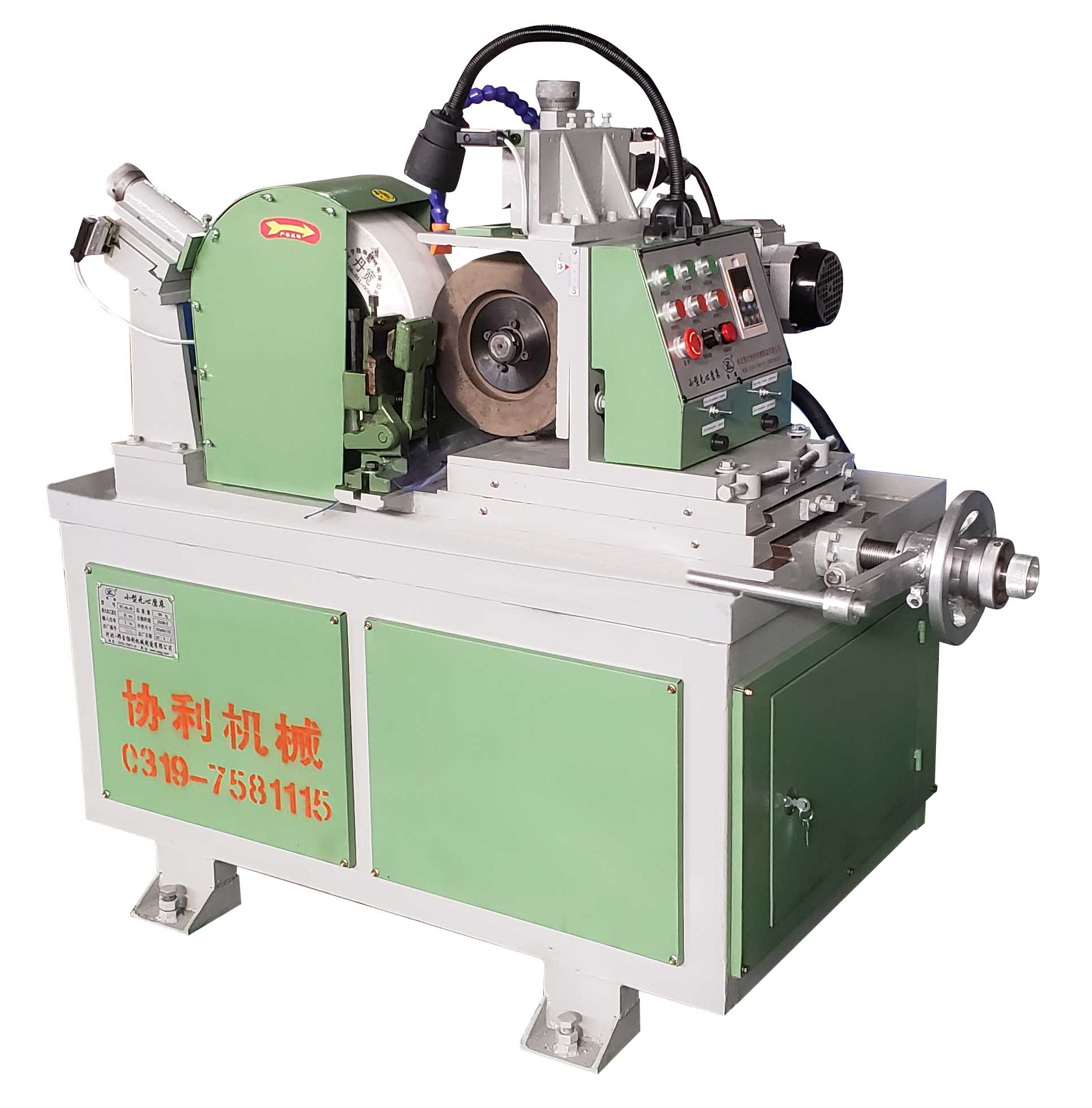

Tube polishing machines are specialized equipment used to achieve a high gloss finish on metal tubes and pipes. These machines effectively remove surface imperfections, contaminants, and oxidation, resulting in smooth, polished surfaces that meet stringent quality standards. The polishing process not only enhances the appearance of the tubes but also improves their resistance to corrosion and wear, making them ideal for various applications.

The Growing Need for Tube Polishing in India

India's rapidly expanding manufacturing sector has led to a surge in the production of metal components, particularly in industries such as automotive, construction, and pharmaceuticals. As companies strive to maintain competitive advantages, the quality of their products has become paramount. Consequently, the demand for tube polishing machines and related services is on the rise. Manufacturers are increasingly investing in advanced polishing technologies to ensure their products not only meet but exceed customer expectations.

Key Benefits of Tube Polishing Machine Services

1. Enhanced Surface Quality One of the primary advantages of using tube polishing machines is the remarkable improvement in the surface finish. Polished tubes exhibit a reflective quality and are free from scratches, blemishes, or any other imperfections, making them suitable for high-end applications.

2. Corrosion Resistance Metal surfaces that are polished are less likely to corrode over time. The polishing process removes oxidized layers and contaminants that could potentially lead to rust or other forms of deterioration, thus extending the lifespan of the components.

3. Time and Cost Efficiency Employing tube polishing machines can significantly reduce the time and labor costs involved in manual polishing processes. Automated machines offer consistent results and can quickly process large volumes of tubes, thereby increasing overall productivity.

tube polishing machine india service

4. Versatility Modern tube polishing machines can accommodate a wide range of materials, including stainless steel, aluminum, and brass. This versatility allows manufacturers to use the same equipment for different projects, making it a cost-effective investment.

5. Environmental Considerations High-quality tube polishing machines often come with features that minimize waste and energy consumption. Many of them operate with advanced technologies that utilize less abrasive material and generate fewer pollutants, aligning with today's sustainability goals.

Choosing the Right Service Provider in India

As the demand for tube polishing services grows, selecting the right service provider becomes crucial. Companies should consider factors such as

- Experience and Expertise Opt for professionals who have a proven track record in tube polishing and understand the specific requirements of different industries.

- Technology and Equipment Ensure the service provider uses state-of-the-art machines that meet international quality standards. Advanced technology can make a significant difference in the quality of the finished product.

- Customer Reviews and Testimonials Feedback from previous clients can provide insight into the reliability and quality of services offered by a provider. Positive testimonials are often indicative of a service provider’s commitment to quality.

- Customization Look for providers who offer customized solutions tailored to specific needs. Whether it's a unique tube size or a specific finish, a good service provider should be able to accommodate unique requirements.

Conclusion

The growth of tube polishing machine services in India reflects the country's expanding manufacturing landscape and the pursuit of higher quality standards. As industries continue to evolve, the need for precision, efficiency, and aesthetic appeal will drive the demand for advanced polishing solutions. By investing in the right tube polishing machines and choosing reliable service providers, manufacturers can enhance their product offerings and maintain a competitive edge in the market. Overall, embracing these technologies is not just a trend but a necessary evolution towards excellence in manufacturing.