Exploring the Benefits of Custom Table Top Centerless Grinders

In the world of precision machining, the need for reliable and efficient grinding solutions is paramount. One of the standout innovations in this field is the custom table top centerless grinder. This versatile tool not only enhances productivity but also brings a host of benefits that cater specifically to the needs of various industries. In this article, we will explore the advantages of using custom table top centerless grinders and their applications in different sectors.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that allows for high-precision grinding of cylindrical workpieces. Unlike traditional grinding machines that require the workpiece to be held at specific points, centerless grinders support workpieces with the help of a grinding wheel and a regulating wheel. This unique arrangement allows for continuous operation without the need for complex setup processes, making it an efficient solution for high-volume production runs.

Customization Meeting Unique Needs

The primary advantage of custom table top centerless grinders is their ability to be tailored to specific requirements. Each industry has unique demands when it comes to precision, size, and material types. By opting for a custom solution, companies can ensure that the grinder meets their exact specifications, whether it involves specific wheel sizes, grinding speeds, or even the type of material being processed.

This customization not only enhances the performance of the grinder but also minimizes wear and tear, leading to longer machine life expectancy. Manufacturers can design their machines to handle a variety of tasks, from grinding small pins and shafts to larger components, making them incredibly versatile.

Space-Saving Design

Another significant advantage of table top centerless grinders is their compact size. Traditional centerless grinders can occupy considerable floor space, which may not be feasible for smaller manufacturing facilities or shops. A table top model, however, offers all the benefits of a standard centerless grinder while maintaining a smaller footprint.

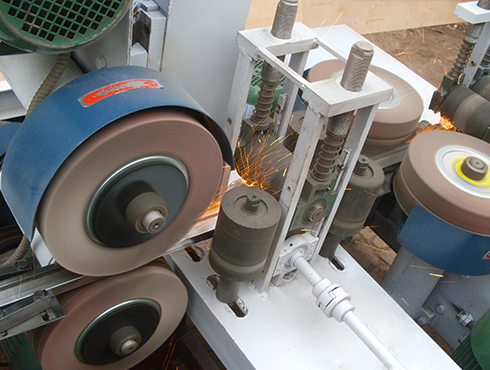

custom table top centerless grinder

This space-saving design allows manufacturers to maximize their workspace by utilizing every available square inch. Furthermore, these machines are often lightweight, making them easier to move and set up in different locations as needed.

Increased Efficiency and Productivity

Custom table top centerless grinders are engineered for efficiency, allowing for faster processing times without compromising precision. Since these machines operate on a continuous cycle, they can significantly reduce downtime associated with loading and unloading workpieces.

Additionally, the integration of advanced technologies such as automated feeding systems can further enhance productivity. With the ability to process multiple parts simultaneously, businesses can achieve higher output rates, making them more competitive in the market.

Precision and Quality Control

Precision is a crucial factor in many manufacturing processes, and custom centerless grinders excel in this regard. With specialized setups, these grinders can achieve tight tolerances that ensure high-quality finishes on machined components. This level of precision is essential in industries such as aerospace, automotive, and medical device manufacturing, where part integrity is critical.

Quality control measures can be integrated into the grinding process itself, allowing for real-time monitoring of dimensions and finishes. This capability helps manufacturers quickly identify and rectify issues, ensuring that every piece meets stringent quality standards.

Conclusion

Custom table top centerless grinders represent a significant advancement in grinding technology. Their tailored designs, space-saving attributes, efficiency, and precision make them an invaluable tool across various industries. As the demand for high-quality, precise components continues to rise, investing in these advanced grinding machines will undoubtedly lead to improved productivity and competitive advantage. For businesses looking to enhance their machining capabilities, a custom table top centerless grinder is a worthwhile consideration.