The Importance of Mirror Polishing in Stainless Steel Pipe Fabrication

In the realms of manufacturing and industrial design, the aesthetic appeal of products is often just as critical as their functionality. This is particularly evident in the processing of stainless steel pipes, where mirror polishing machines play a vital role. These machines not only enhance the visual quality of stainless steel products but also contribute to their overall performance and durability.

Stainless steel, known for its resistance to corrosion and staining, is widely used in various industries, including construction, automotive, and food processing. However, raw stainless steel has a dull, matte finish that may not be suitable for certain applications where appearance is paramount. This is where mirror polishing comes into play. Utilizing advanced mirror polishing machines, manufacturers can transform the surface of stainless steel pipes, resulting in a high-gloss finish that is both attractive and functional.

Mirror polishing involves several processes that work to improve the surface finish of stainless steel pipes. Initially, the pipes undergo grinding to remove imperfections and create a uniform surface. Following this, finer abrasives are used to gradually buff the pipes until they achieve a shimmering, reflective finish. The polishing not only enhances the aesthetic aspect but also provides practical benefits. A smooth, mirror-like surface is more resistant to dirt and grime accumulation, making it easier to clean and maintain. This is particularly important in industries where hygiene and cleanliness are paramount, such as in food and beverage processing.

The efficiency of modern mirror polishing machines is notable. These machines are designed with advanced technology to ensure precise and consistent results. With automated processes, manufacturers can achieve high productivity while minimizing labor costs and reducing human error. Many of these machines are equipped with features like variable speed controls, automatic feeding systems, and advanced monitoring capabilities that enhance operational efficiency.

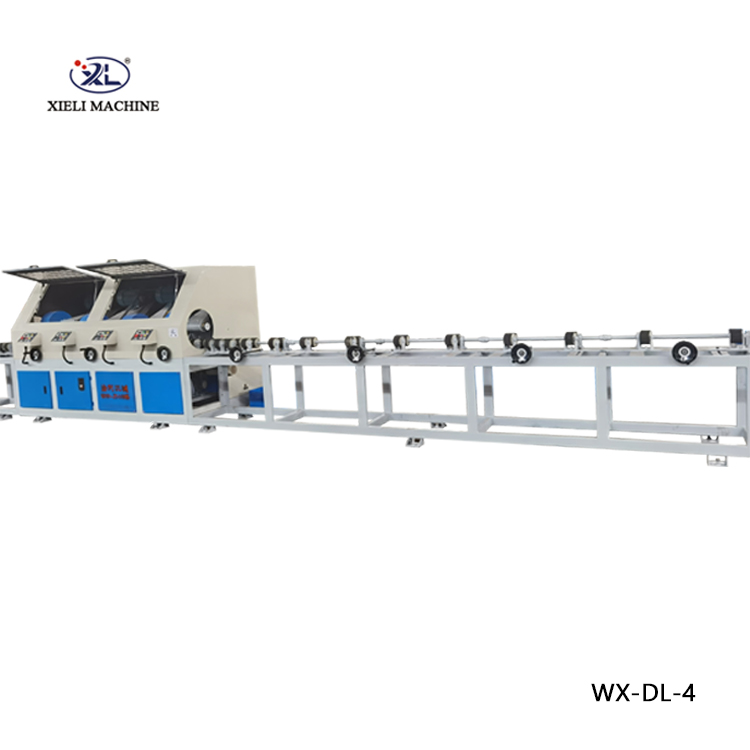

famous stainless steel pipe mirror polishing machine

Moreover, the importance of reliable mirror polishing machines can’t be overstated in terms of quality assurance. The final finish of a stainless steel pipe can significantly influence its usability and longevity. With rigorous quality standards being enforced globally, manufacturers are increasingly relying on high-grade polishing machines to conform to these specifications. A well-polished pipe is more likely to withstand environmental factors, thus ensuring a longer lifespan and reducing overall maintenance costs.

In addition to the functional benefits, the visual appeal of mirror-polished stainless steel pipes provides a competitive edge in the market. An aesthetically pleasing product is more likely to capture the attention of potential customers, influencing purchasing decisions. This is especially relevant in sectors like architecture and design, where the elegance of materials plays a crucial role in project outcomes. Stainless steel pipes with a mirror finish can significantly enhance the overall look of a building or installation, making them a preferred choice for architects and designers.

As sustainability becomes an increasingly important consideration in manufacturing, it's worth noting that stainless steel is a highly recyclable material. Mirror polishing machines, when utilized efficiently, adhere to sustainable practices. They often consume less energy and generate minimal waste compared to traditional finishing methods. This aligns with modern manufacturing trends that prioritize environmental responsibility while maintaining high production standards.

In conclusion, the role of famous stainless steel pipe mirror polishing machines cannot be understated. These machines are essential for enhancing the aesthetic and functional qualities of stainless steel pipes, providing benefits such as improved hygiene, increased durability, and attractive appearance. The advancements in polishing technology continue to progress, promising even greater efficiencies and quality in the future of stainless steel fabrication. As industries evolve and demand for high-quality materials increases, the significance of effective mirror polishing processes will undoubtedly remain at the forefront of manufacturing practices.