Custom Centerless Grinder Suppliers Meeting Precision Needs in Manufacturing

In the ever-evolving landscape of modern manufacturing, precision and efficiency are paramount. One critical component that plays a significant role in achieving these goals is the centerless grinder. Unlike traditional grinding machines, centerless grinders offer unique advantages, particularly in producing cylindrical parts with high tolerances and surface finishes. For manufacturers looking to enhance their production capabilities, sourcing from specialized custom centerless grinder suppliers can make a substantial difference.

Understanding Centerless Grinding

Centerless grinding is a machining process that eliminates the need for a spindle and fixture. Instead, the workpiece is supported by a conveyor and ground between two grinding wheels. This method allows for continuous, high-volume production without the downtime associated with traditional grinding. The two primary types of centerless grinding are through-feed and in-feed grinding, each tailored to specific applications.

Through-feed grinding is ideal for processing long, cylindrical parts that can be fed continuously. In contrast, in-feed grinding is suited for shorter components with complex shapes where loading is done manually. Both methods require precise alignment and consistency to ensure high-quality outputs — a requirement that custom centerless grinder suppliers can meet through their specialized machinery and expertise.

The Value of Customization

Not all manufacturing processes are identical. Each industry has unique requirements regarding dimensions, tolerances, and materials. This is where the value of custom centerless grinder suppliers comes into play. These suppliers work closely with manufacturers to develop grinding solutions that align with specific needs. This includes

1. Tailored Machinery Custom suppliers can design and manufacture grinding machines that cater to the specific needs of a business, optimizing for size, speed, and precision. Whether it's adjusting the design for different material types or enhancing throughput, custom solutions can significantly boost productivity.

2. Versatile Applications Various industries, from automotive and aerospace to medical devices and electronics, require different grinding applications. Custom centerless grinder suppliers often have the flexibility to accommodate these diverse applications, ensuring that the machinery can adapt to various product specifications.

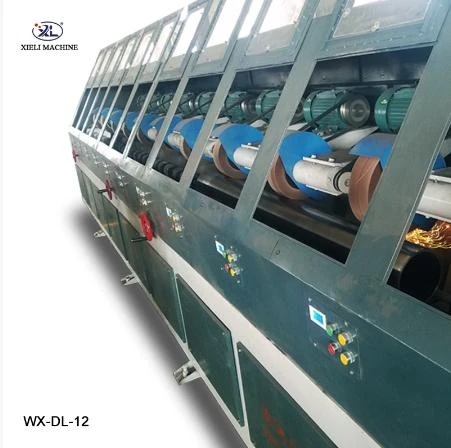

custom centerless grinder suppliers

3. Advanced Technology Technology in the grinding sector is continuously evolving. Custom suppliers often integrate the latest technology into their machines, such as CNC controls, automated feeding systems, and advanced monitoring systems. This not only improves efficiency but also enhances the precision of the grinding process.

Selecting the Right Supplier

With many options available, selecting the right custom centerless grinder supplier is crucial. Here are some key factors to consider

1. Expertise and Experience Suppliers with a solid background in centerless grinding can provide valuable insights and recommendations tailored to your specific needs. Look for companies with a proven track record and positive client testimonials.

2. Quality Assurance Ensure the supplier adheres to stringent quality control measures. This includes not just the quality of the machines but also the materials used and the manufacturing process itself. Certifications such as ISO can be a good indicator of a supplier's commitment to quality.

3. Support and Service A reliable custom centerless grinder supplier should offer robust after-sales support, including maintenance services, spare parts availability, and troubleshooting assistance. This will ensure that any issues with the machinery are addressed quickly to minimize downtime.

4. Innovation The best suppliers continuously invest in research and development. Look for suppliers who are committed to innovating their products and processes, ensuring that you receive state-of-the-art grinding solutions that keep you competitive.

Conclusion

As the demand for precision and efficiency in manufacturing continues to grow, the role of custom centerless grinder suppliers becomes increasingly vital. By offering tailored solutions, advanced technology, and ongoing support, these suppliers can help businesses optimize their production processes. For manufacturers aiming to enhance their grinding capabilities and remain competitive in the market, partnering with a reliable custom centerless grinder supplier is a strategic move that can yield significant returns on investment. Investing in the right equipment and support will not only help in achieving precision but also drive productivity, ultimately leading to higher customer satisfaction and growth in the competitive manufacturing landscape.