Centerless Belt Grinders for Sale A Guide for Buyers

Centerless belt grinders have become an essential tool for many industries, particularly in manufacturing and metalworking. These machines provide a unique method of grinding that allows for high precision and efficiency, making them highly sought after. If you're in the market for a centerless belt grinder, this article will guide you through the features, benefits, and factors to consider, along with a look at suppliers available on the market.

What is a Centerless Belt Grinder?

A centerless belt grinder is a type of grinding machine that utilizes abrasive belts to remove material from the surface of a workpiece. Unlike traditional grinders that require the workpiece to be supported at both ends, centerless grinders work without centering the part. The workpiece is held in place between a grinding belt and a regulating wheel, allowing for a continuous grinding process. This method is particularly effective for cylindrical parts that need to have precise dimensions and smooth finishes.

Benefits of Centerless Belt Grinders

1. Efficiency Centerless grinding can produce multiple parts in a shorter amount of time compared to conventional grinding methods. The continuous operation allows for faster processing of materials, which can significantly improve productivity in a manufacturing setting.

2. Precision These grinders can achieve tight tolerances and high quality finishes, making them ideal for intricate components used in industries like aerospace, automotive, and medical device manufacturing.

3. Versatility They can accommodate various materials, including metals, plastics, and composites. This versatility makes them suitable for a wide range of applications, from simple shaping to complex finishing tasks.

4. Cost-Effectiveness While initial investments may be higher than traditional grinders, the long-term savings in time and material waste can lead to overall cost reductions.

Key Features to Consider

When selecting a centerless belt grinder, here are some important features to look for

1. Belt Size and Type Different belt sizes can affect the grinding capacity. Consider whether you need a large surface area for bigger parts or a more compact model for smaller items. The type of abrasive belt also matters; options can include different grits that are tailor-suited to specific materials.

centerless belt grinder for sale suppliers

2. RPM and Power The speed at which the grinder operates (measured in RPM) is crucial. Higher RPM typically leads to faster grinding, but make sure the machine has adequate power to maintain performance under load.

3. Adjustability A machine with adjustable settings for belt tension and height can improve usability and allow for various grinding tasks without needing extensive recalibration.

4. Durability A sturdy design will ensure longevity and reduce maintenance costs. Look for grinders made from high-quality materials that can withstand the rigors of a production environment.

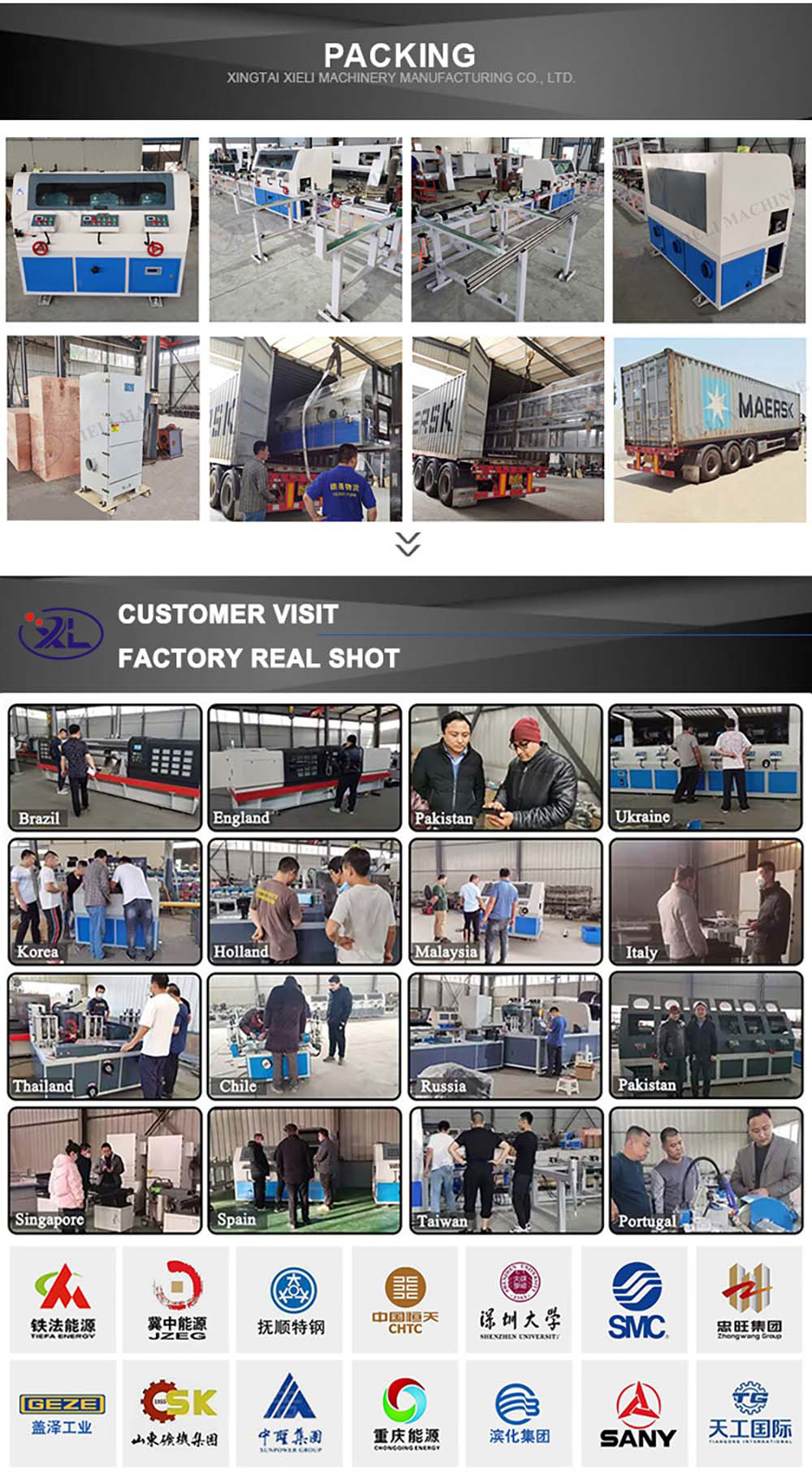

Finding Reliable Suppliers

When searching for centerless belt grinders, it’s essential to identify reliable suppliers who can meet your needs. Here are some factors to consider when evaluating potential suppliers

1. Reputation Look for companies with a solid reputation in the industry. Customer reviews and testimonials can provide insights into their reliability and customer service.

2. Technical Support Ensure that the supplier offers comprehensive support, including installation, maintenance, and troubleshooting assistance.

3. Warranty and Service Options A good warranty can reflect the manufacturer’s confidence in their product. Additionally, inquire about servicing options and availability of replacement parts.

4. Pricing Compare prices from different suppliers, but also weigh this against the quality and features of the grinders offered. The cheapest option may not always be the best investment.

Conclusion

Centerless belt grinders play a crucial role in the manufacturing process by enhancing efficiency, precision, and cost-effectiveness. By understanding the benefits and essential features of these machines, along with what to consider when selecting a supplier, you can make an informed decision that will significantly impact your operations. Whether you're sharpening tools or finishing components, investing in a quality centerless belt grinder can elevate your production capabilities to new heights.