Understanding the Role of Centerless Grinder Operator Manufacturers

In today’s manufacturing landscape, precision and efficiency are paramount. One of the critical processes that achieves these goals is grinding, particularly using centerless grinding technology. This article delves into the significance of centerless grinder operator manufacturers, their role in the industry, the technology involved, and the future outlook.

What is Centerless Grinding?

Centerless grinding is a unique machining process that allows for the grinding of cylindrical workpieces without the need for a spindle or fixture to hold the workpiece. Instead, the workpiece is supported by a work rest blade and the grinding wheel, making it a preferred method for producing high-precision parts with efficient throughput. Common applications include automotive components, aerospace parts, and various industrial machinery components.

The Role of Centerless Grinder Operator Manufacturers

Centerless grinder operator manufacturers play a vital role in the supply chain, providing the machinery, tools, and expertise needed for effective grinding operations. They design, manufacture, and supply centerless grinding machines tailored to various industrial requirements. These manufacturers are responsible for ensuring that their machines offer precision, reliability, and durability.

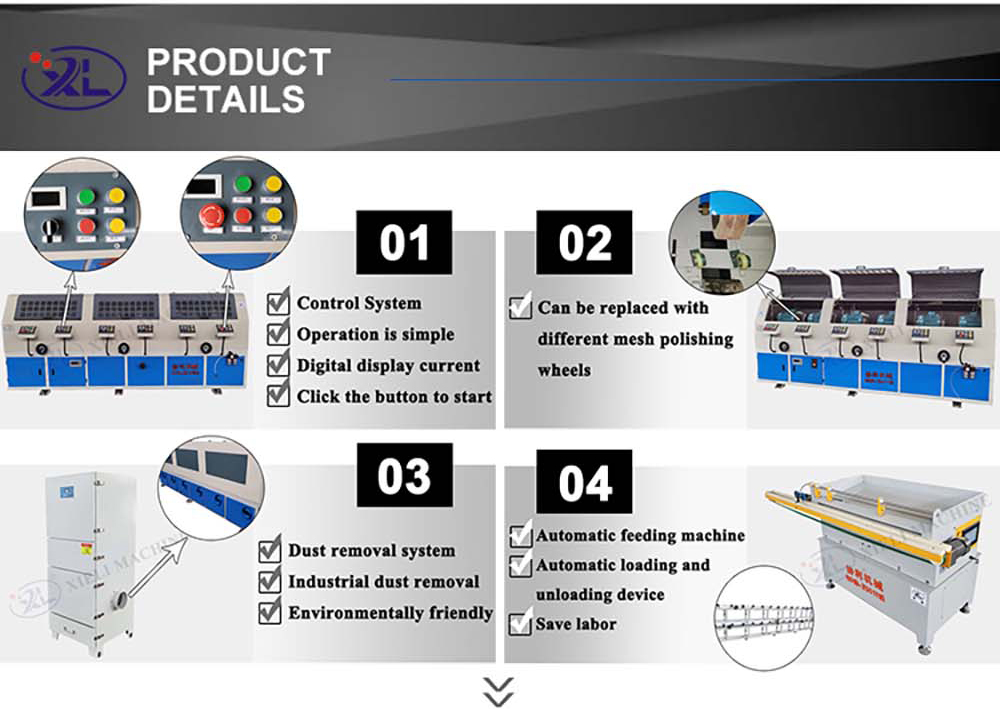

1. Machine Design and Innovation Centerless grinder operators must focus on the innovative design of their equipment to enhance performance and productivity. This includes developing grinding systems that incorporate advanced technology such as CNC (Computer Numerical Control) capabilities for automated operations. Such features help in achieving tighter tolerances and higher efficiency in production runs.

2. Training and Support Beyond providing machinery, manufacturers often offer training programs for operators to ensure they understand how to use the equipment effectively. Given the complexities of centerless grinder operations, having knowledgeable operators can significantly improve output quality while reducing waste.

3. Customization Different industries require different specifications. Centerless grinder operator manufacturers often work closely with their clients to customize machines that best fit their specific needs. This adaptability is crucial as industries evolve and demand shifts.

centerless grinder operator manufacturers

4. Maintenance and Service Regular maintenance is essential for optimal machine performance. Manufacturers typically provide ongoing service support, which can include routine check-ups, repairs, and the provision of spare parts. Having a reliable support system in place minimizes downtime and keeps production lines operating smoothly.

Importance in Various Industries

Centerless grinding is prevalent across many sectors, notably in automotive and aerospace manufacturing. For instance, automotive companies rely on this technology for producing precise crankshafts, camshafts, and other essential components. In aerospace, the need for lightweight and high-strength parts makes centerless grinding invaluable for meeting tight tolerances and performance specifications.

Furthermore, as industries become more competitive, companies are always on the lookout for ways to enhance their processes. Centerless grinding presents an opportunity to streamline operations, reduce costs, and improve overall product quality.

Future Outlook

The future of centerless grinder operator manufacturers appears promising. With the advancement of Industry 4.0 concepts and smart manufacturing, there is a growing trend towards the integration of IoT (Internet of Things) technology into grinding machines. This integration allows operators to monitor machine performance in real-time, predict maintenance needs, and optimize production schedules.

Moreover, as sustainability becomes a focal point in manufacturing, there is a push towards minimizing waste and maximizing resource efficiency. Centerless grinder operators are well-positioned to develop solutions that align with these sustainable practices.

Conclusion

Centerless grinder operator manufacturers are a cornerstone of modern manufacturing, playing an essential role in delivering precision machinery and supporting operators in maximizing productivity. As technology advances and industries evolve, these manufacturers are set to continue leading the charge in innovative grinding solutions. Their contribution not only enhances operational efficiency but also helps meet the rigorous demands of various sectors, ensuring the production of high-quality components that drive the global economy forward.