The Global Market for Stainless Steel Tube Polishing Machines Trends and Export Insights

In recent years, the demand for stainless steel tube polishing machines has surged, driven by the growing industries of construction, automotive, and manufacturing that require high-quality finishes on stainless steel components. These machines play a crucial role in creating aesthetically appealing and operationally efficient products, making them an essential tool for manufacturers and exporters. As the global market for these machines expands, it becomes increasingly important to understand the trends influencing their export dynamics.

Understanding the Market Demand

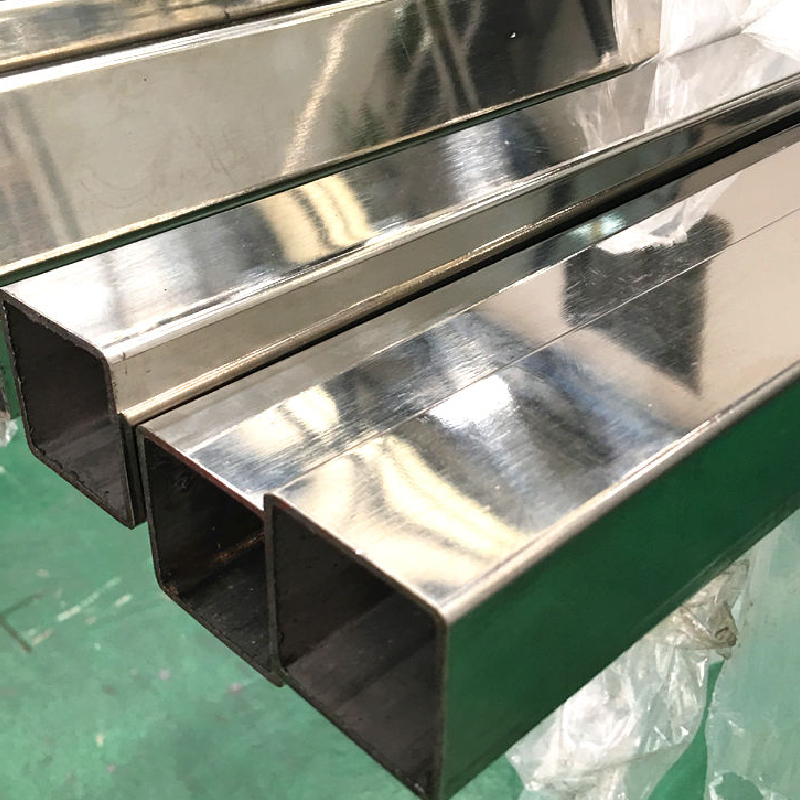

Stainless steel is known for its durability, corrosion resistance, and clean appearance, making it a material of choice in many sectors. Industries such as food and beverage, pharmaceuticals, and architecture heavily rely on polished stainless steel tubes for various applications. The trend toward modernization and improvement in manufacturing processes has led to an increase in demand for advanced polishing machines that can handle intricate designs and higher production volumes. As companies across the globe prioritize quality and efficiency, the stainless steel tube polishing machine market is poised for growth.

Key Export Destinations

Countries with robust manufacturing bases, including Germany, Italy, Japan, and the United States, are significant players in the export of stainless steel tube polishing machines. These nations are known for their technological advancements and craftsmanship in machine manufacturing, often leading the way in developing state-of-the-art polishing technology. Additionally, emerging markets in Asia, such as China and India, are rapidly increasing their production capabilities, leading to a higher demand for polishing machines.

The Middle East and Africa are also gaining traction as notable destinations for these machines, primarily driven by infrastructural developments and an increase in manufacturing activities

. With a surge in construction projects and the need for high-quality materials, the demand for stainless steel tube polishing machines is expected to increase significantly in these regions.Technological Innovations

stainless steel tube polishing machine exporters

Innovation and advancements in technology are transforming the landscape of stainless steel tube polishing. Manufacturers are increasingly integrating automation and robotic systems into their polishing machines to enhance efficiency and precision. Automated polishing systems not only reduce labor costs but also ensure consistent quality across large production runs. Digital controls, user-friendly interfaces, and real-time monitoring are becoming standard features, facilitating ease of use and reducing the learning curve for operators.

Moreover, eco-friendly polishing techniques are gaining popularity as industries strive to reduce their environmental impact. Machines that utilize less energy and produce fewer waste materials are increasingly sought after, aligning with global sustainability goals. As a result, manufacturers that prioritize green technologies in their polishing machines are more likely to capture a significant share of the export market.

Challenges in the Export Landscape

Despite the promising outlook, exporters of stainless steel tube polishing machines face several challenges. Trade regulations, tariffs, and compliance with international standards can complicate the export process. Companies must navigate complex logistical issues, ensuring timely delivery while managing costs effectively. Additionally, maintaining competitiveness in pricing while delivering high-quality machines poses a significant challenge for many manufacturers.

Moreover, the global supply chain disruptions caused by events such as the COVID-19 pandemic have highlighted the vulnerabilities in international trade. Exporters must adapt their strategies to mitigate risks associated with supply chain issues, including sourcing raw materials and managing production timelines.

Conclusion

The stainless steel tube polishing machine export market presents numerous opportunities for manufacturers and exporters, driven by growing demand across various industries. With technological advancements fostering innovative solutions and an increasing focus on sustainability, the landscape is evolving rapidly. However, potential challenges, such as regulatory hurdles and supply chain disruptions, require careful navigation. By embracing innovation, adopting sustainable practices, and strategically targeting emerging markets, exporters can effectively position themselves in this dynamic and expanding arena. The future of stainless steel tube polishing machines looks bright, promising continued growth and evolution in the global marketplace.