The Rise of Automatic Metal Polishing Machine Manufacturers

In the fast-evolving world of manufacturing, the quest for efficiency and quality has led to the development of various automated solutions. One of the significant advancements in this arena is the emergence of automatic metal polishing machines. These sophisticated devices are designed to enhance the finishing process of metal components, ensuring they meet the stringent quality standards demanded by various industries, including automotive, aerospace, and electronics.

Understanding Automatic Metal Polishing Machines

Automatic metal polishing machines utilize advanced technology to achieve a high sheen on metal surfaces. They typically employ various polishing techniques such as rotary, vibratory, and centrifugal methods, depending on the application and desired finish. The machines are programmed to handle different types of metal, including steel, aluminum, brass, and titanium, providing manufacturers with versatility and efficiency in their operations.

The operation of these machines reduces the need for manual labor, significantly cutting down production time while maintaining consistent quality. This is particularly vital in industries where high-volume production is necessary, as it enhances productivity and minimizes human error. Automatic polishing machines are increasingly integrated with computer numerical control (CNC) systems, allowing for precise control and customization of the polishing process.

The Benefits of Automation in Metal Polishing

The transition to automatic metal polishing machines offers numerous benefits. Firstly, these machines provide uniform finishing, which is crucial for parts that require a consistent aesthetic and functional quality. A uniform polish not only improves the appearance but also helps in reducing oxidation and corrosion, which can enhance the lifespan of metal products.

Secondly, the efficiency of these machines leads to lower operational costs. By reducing the labor intensity of the polishing process, manufacturers can allocate resources more effectively, redirecting human efforts toward more complex tasks that require critical thinking and problem-solving skills. This strategic allocation helps companies maintain a competitive edge in their respective markets.

Furthermore, automatic polishing machines contribute to the overall safety of the manufacturing environment. By minimizing manual intervention in potentially hazardous polishing processes, manufacturers can reduce the risk of workplace injuries. This shift not only safeguards employees but also ensures compliance with occupational health and safety regulations.

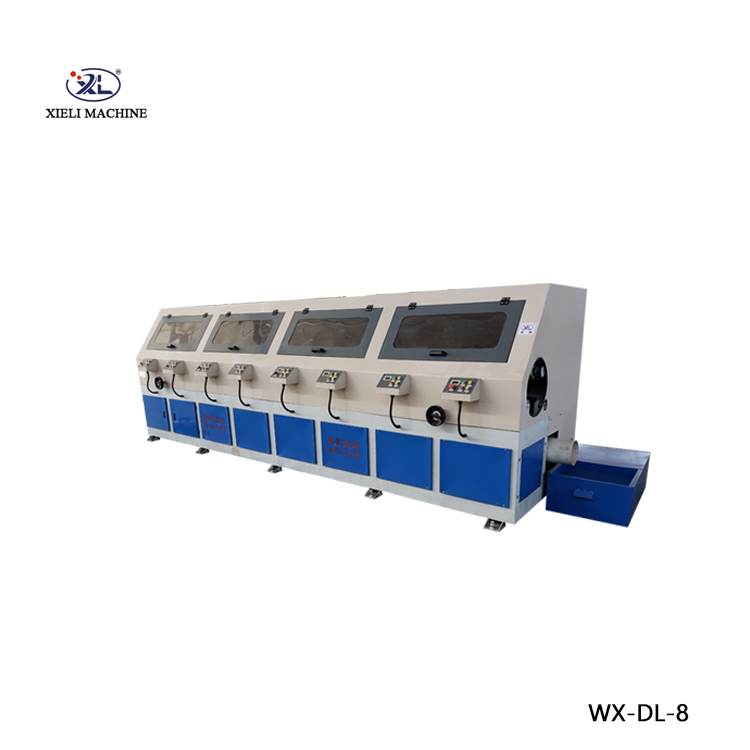

automatic metal polishing machine manufacturers

The Market for Automatic Metal Polishing Machine Manufacturers

As industries continue to seek effective solutions for their polishing needs, the market for automatic metal polishing machine manufacturers is expanding. Numerous manufacturers are emerging globally, introducing innovative products that cater to specific industry requirements. These companies are focusing on advancements in technology, such as the integration of artificial intelligence and IoT (Internet of Things) capabilities, to create smarter and more efficient polishing solutions.

Additionally, manufacturers are increasingly prioritizing sustainability in their processes. Environmentally friendly polishing methods and recyclable materials are becoming key considerations, leading to the development of machines that minimize waste and consumption of resources.

Choosing the Right Manufacturer

When selecting an automatic metal polishing machine manufacturer, several factors must be considered. It is crucial to assess the company’s reputation, experience, and customer feedback. A manufacturer with a proven track record in the industry is more likely to provide reliable products and services.

Moreover, potential buyers should evaluate the range of machine options offered, ensuring they meet specific polishing requirements. Some manufacturers specialize in niche markets or unique polishing techniques, which may be more suitable depending on the application.

Finally, after-sales support is another critical aspect to consider. A manufacturer that offers comprehensive training, maintenance, and technical support can help companies maximize the utility of their polishing machines, leading to better performance and extended machine life.

Conclusion

The landscape of metal manufacturing is transforming with the rise of automatic metal polishing machines. These machines are revolutionizing the way metal components are polished, providing manufacturers with a reliable, efficient, and cost-effective solution. As the market for these machines continues to grow, choosing the right manufacturer will be key to harnessing the benefits of this technology. Embracing automation in the polishing process not only enhances production but also positions companies to meet the demands of an increasingly competitive marketplace.