Handheld Pipe Polishing Machines Revolutionizing Surface Finishing

In today’s fast-paced manufacturing environment, the demand for high-quality finishes on metal surfaces is paramount. Whether in the automotive industry, construction, or custom metal fabrication, the need for precision and efficiency drives innovation. Enter handheld pipe polishing machines, a game-changer in the realm of surface finishing.

What is a Handheld Pipe Polishing Machine?

A handheld pipe polishing machine is a portable device designed to smooth out the surfaces of pipes and tubes. These machines are equipped with various polishing attachments, allowing operators to achieve a mirror-like finish on different types of metal, including stainless steel, aluminum, and brass. They are particularly useful for polishing welds, removing surface imperfections, and preparing surfaces for further treatments, such as coating or painting.

Benefits of Handheld Pipe Polishing Machines

1. Portability and Versatility As the name suggests, handheld polishing machines are easy to maneuver. Their portable design allows operators to work in confined spaces and on-site, making them ideal for job sites or workshops with limited space. Unlike bulkier machinery that requires extensive setup, these tools can be quickly employed wherever they're needed.

2. Precision and Control Handheld machines provide operators with a greater degree of control over the polishing process. This is crucial for intricate jobs where specific areas require special attention. The ergonomic design allows for ease of use, reducing fatigue during prolonged periods of operation, which is common in industries that rely heavily on metal work.

3. Cost-Effectiveness Investing in a handheld pipe polishing machine can yield significant savings in labor costs. As these machines streamline the finishing process, they reduce the time and manpower required to achieve high-quality surfaces. Additionally, the long lifespan and low maintenance needs of these machines contribute to their cost-effectiveness.

4. Enhanced Finish Quality One of the primary advantages of using a handheld pipe polishing machine is the quality of the finish it can achieve. With proper operation, these machines can deliver a high-gloss finish that meets or exceeds industry standards. This is particularly important in sectors where aesthetics are as critical as functionality, such as in decorative metalwork or in the production of high-end appliances.

hand held pipe polishing machine company

5. Adaptability to Various Materials Handheld polishing machines are designed to handle a wide array of materials. The ability to switch polishing pads or brushes means that a single machine can be utilized for different tasks, making it an invaluable tool for metal workers who often switch between tasks and materials.

Choosing the Right Handheld Pipe Polishing Machine

When selecting a handheld pipe polishing machine, several factors should be considered

- Power and Speed Different applications may require machines with varying power ratings and speeds. Higher RPMs often result in quicker polishing but may require a more skilled hand to control effectively.

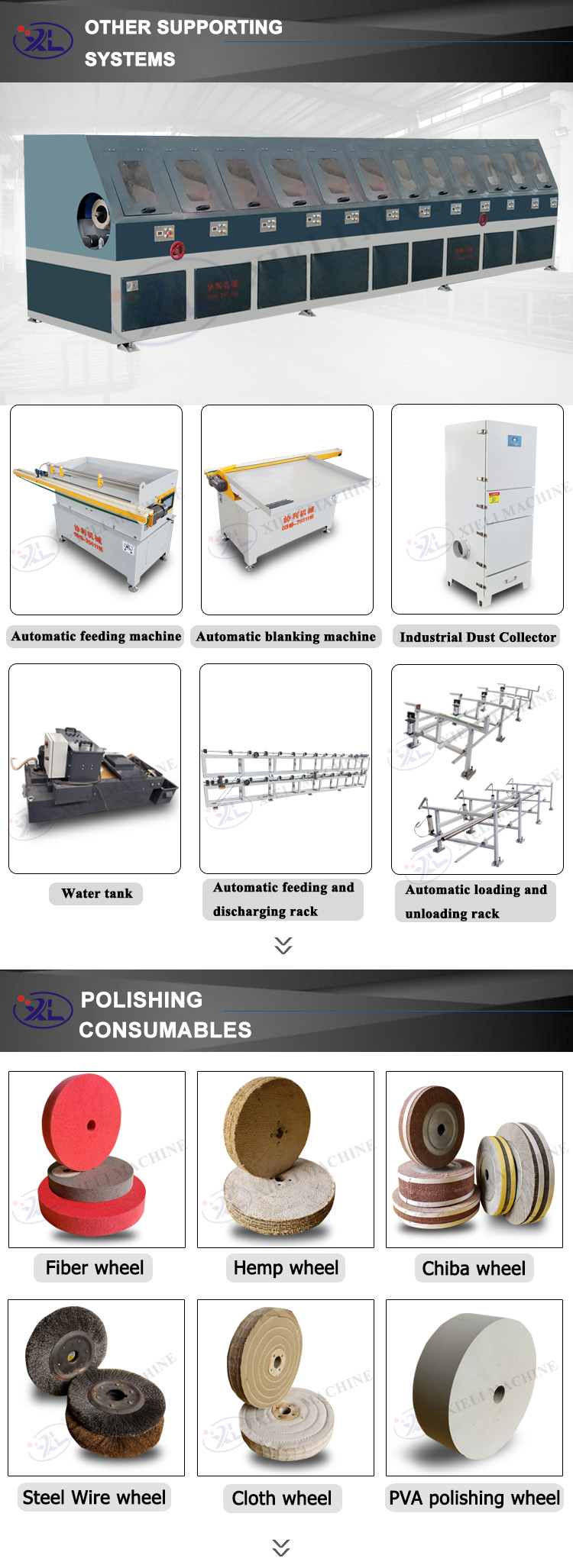

- Attachments and Accessories Look for machines that offer a range of attachments, including different types of polishing pads, brushes, and abrasives tailored for specific materials and finishes.

- Ergonomics As operators will spend extended periods using these machines, ergonomic design should be a top priority. Features like adjustable handles, lightweight construction, and vibration reduction can significantly enhance the user experience.

- Durability and Reliability Investment in quality equipment is crucial. Look for machines from reputable manufacturers known for their durability and reliable performance over time.

Conclusion

Handheld pipe polishing machines have become indispensable tools across various industries due to their portability, precision, and ability to deliver high-quality finishes. By taking into account factors such as power, attachments, ergonomics, and durability, businesses can choose the right equipment to enhance their efficiency and output quality. As technology continues to innovate, these machines will likely evolve to meet the ever-changing demands of the market, solidifying their place as essential tools for modern metalworking operations. Embracing these advancements not only improves production processes but also elevates the standards of workmanship in metal fabrication.