Cincinnati 220-8 Centerless Grinder A Forge of Precision Engineering

In the world of manufacturing, precision is not merely a goal; it is a necessity. Among the machinery that epitomizes this principle is the Cincinnati 220-8 Centerless Grinder. Known for its reliability and accuracy, the Cincinnati 220-8 has earned its place as a crucial tool in various industrial processes, from automotive to aerospace and everything in between.

The history of Cincinnati, Ohio, is deeply intertwined with the development of manufacturing technologies. Founded over a century ago, the city became a hub for innovative machine tool designs, and the Cincinnati Milling Machine Company was at the forefront of this evolution. The 220-8 Centerless Grinder is one such innovation that has stood the test of time. Designed for grinding cylindrical workpieces without the need for a central spindle, this machine is celebrated for its capability to deliver high-quality finishes on a wide range of materials.

Centerless grinding relies on a unique setup where the workpiece is supported by a blade or rest placed between two grinding wheels. The Cincinnati 220-8 holds a reputation for its robust build and exceptional performance, making it a favored choice among manufacturers. It allows for the grinding of parts with diameters as small as 0.0625 inches and lengths of up to 40 inches, making it versatile enough to accommodate a variety of applications.

One of the defining features of the Cincinnati 220-8 is its user-friendly operation. The machine is equipped with advanced controls that enable operators to easily adjust grinding parameters, ensuring optimal performance. This automation not only enhances productivity but also minimizes the risk of human error, a critical factor in achieving consistent quality in parts production.

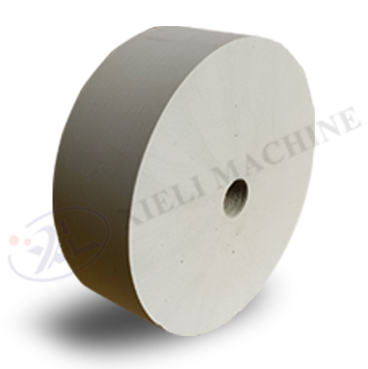

cincinnati 220 8 centerless grinder factory

Moreover, the machine’s design incorporates a variety of features aimed at increasing efficiency and minimizing downtime. The hydraulic feed system, for example, ensures that parts are fed at a controlled rate, reducing the likelihood of grinding errors due to improper positioning. Additionally, the availability of different wheel options makes it possible to optimize performance based on the specific requirements of the job, whether it involves rough grinding or achieving a fine finish.

Maintenance is another area where the Cincinnati 220-8 shines. With its straightforward design, routine upkeep is simplified, allowing for quick adjustments and repairs when necessary. This reliability not only results in reduced operational costs but also extends the life of the machine, making it a worthwhile investment for any manufacturing outfit.

In an era where manufacturing demands are ever-increasing, the Cincinnati 220-8 Centerless Grinder stands out as a beacon of efficiency, reliability, and performance. Its legacy is not just a testament to its engineering excellence but a reflection of the ongoing commitment to innovation in manufacturing technologies.

For those looking to enhance their production capabilities, investing in a Cincinnati 220-8 Centerless Grinder represents a strategic decision that can yield significant returns. As industries continue to evolve, tools like the Cincinnati 220-8 will undoubtedly play an indispensable role in meeting the challenges of modern manufacturing, ensuring precision and quality remain at the forefront of production standards.