Revolutionizing Efficiency The Role of Cheap Centerless Grinder Automation

In the increasingly competitive manufacturing landscape, companies are perpetually seeking ways to elevate productivity while minimizing costs. One significant advancement in this sphere is the automation of centerless grinding, particularly through affordable options designed for small to medium enterprises (SMEs). This article delves into the benefits, technologies, and future prospects of cheap centerless grinder automation, offering insights into why it is an essential investment for modern manufacturing.

Understanding Centerless Grinding

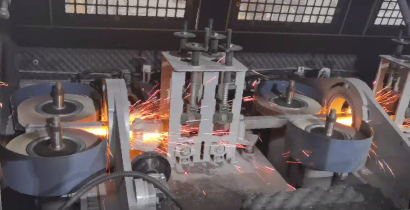

Centerless grinding is a machining process that removes material from the outside diameter of a workpiece. Unlike traditional grinding processes where the workpiece is held between centers, centerless grinding uses a pair of rotary wheels—one for grinding and one for support—to enable continuous operation. This efficiency allows for high-volume production and tight tolerance levels, making it a preferred choice for producing cylindrical parts.

The Need for Automation

In a world where efficiency is king, the automation of centerless grinders has emerged as a critical strategy to meet growing demands. Automation improves the machining process by increasing throughput, reducing labor costs, and enhancing consistency in part quality. For SMEs, investing in cheap automation solutions provides a pathway to compete with larger players without straining their budgets.

Key Benefits of Cheap Centerless Grinder Automation

1. Cost-Effectiveness The foremost appeal of cheap automation lies in its affordability. Budget-friendly automation solutions for centerless grinders make it easier for smaller manufacturers to implement state-of-the-art technology without incurring massive expenses.

2. Enhanced Productivity Automated centerless grinders significantly increase output by minimizing manual labor. Continuous operation with minimal downtime results in higher production rates and faster turnaround times.

3. Improved Precision Automated systems offer advanced functionality, ensuring that parts are produced with consistent quality and precision. This consistency reduces the risk of defects and enhances overall product reliability.

4. Labor Savings Automation reduces the reliance on skilled labor, a crucial factor as labor shortages persist in many regions. Operators can focus on higher-level tasks as the machine handles repetitive processes.

cheap centerless grinder automation

5. Scalability Affordable automation solutions are often designed with scalability in mind. As businesses grow, they can easily upgrade their systems to accommodate increased production demands without requiring a complete overhaul.

Technologies Behind Cheap Centerless Grinder Automation

Several technologies are at the forefront of making centerless grinder automation affordable and efficient.

1. PLC (Programmable Logic Controllers) PLCs are central to automating grinding processes. They provide real-time monitoring and control, enabling precise adjustments to the grinding parameters to meet specific production needs.

2. Robotics The integration of robotic arms for loading and unloading parts can drastically reduce the time required for manual handling. Robotic systems can be programmed for various tasks, ensuring flexibility and adaptability in production lines.

3. Smart Sensors Incorporating sensors into centerless grinding machines can help monitor machine performance and part quality. These sensors allow for predictive maintenance, minimizing downtime and extending machine lifespan.

4. User-Friendly Interfaces Many affordable automated systems now come equipped with intuitive interfaces that make operation straightforward, even for less experienced staff. This user-friendliness encourages widespread adoption in the workforce.

Future Prospects

The future of cheap centerless grinder automation looks promising as technological advancements continue to emerge. The introduction of AI-driven solutions will likely lead to even greater efficiency, with machines capable of learning from previous operations to optimize processes autonomously. Affordable automation will empower more SMEs to harness these innovations, leveling the playing field in the manufacturing sector.

Conclusion

In conclusion, cheap centerless grinder automation represents a transformative opportunity for manufacturers striving to enhance efficiency while controlling costs. With its myriad of benefits, from increased productivity to improved precision and reduced labor reliance, companies cannot afford to overlook this essential innovation. As technology advances, the affordability and accessibility of such automated solutions will continue to shape the future of manufacturing, enabling businesses of all sizes to thrive in an ever-evolving market. Embracing automation is not merely advantageous; it is becoming a necessity in the quest for sustained competitiveness.