The Advantages of Wholesale Centerless Grinder Machines

In the world of manufacturing and metalworking, precision is key. Centerless grinder machines have become a fundamental element in this industry due to their ability to produce parts with high precision and efficiency. As businesses look for ways to optimize their production processes, moving toward wholesale centerless grinder machines is a strategic choice that offers numerous advantages.

What are Centerless Grinders?

Centerless grinders are versatile machines used for grinding cylindrical parts without the need for a central axis. Unlike traditional cylindrical grinding machines that require the part to be mounted between centers, centerless grinders allow the part to be fed through the machine, which significantly increases production speed. The basic principle involves a grinding wheel, a regulating wheel, and a workpiece that is supported by the wheels.

Key Benefits of Wholesale Centerless Grinder Machines

1. Cost Efficiency Purchasing centerless grinder machines wholesale allows manufacturers to save significantly on capital expenditures. When buying in bulk, businesses often benefit from reduced pricing, which can lead to substantial savings. As a result, companies can invest more in other areas of their operations, such as research and development, marketing, or workforce training.

2. High Precision and Consistency Centerless grinders are known for their ability to achieve tight tolerances and high levels of precision. By using these machines, manufacturers can produce parts that meet stringent quality standards. Additionally, the consistent grinding process minimizes the risk of human error, ensuring that each piece meets specifications. This reliability is crucial for industries such as automotive, aerospace, and medical, where precision can directly affect performance and safety.

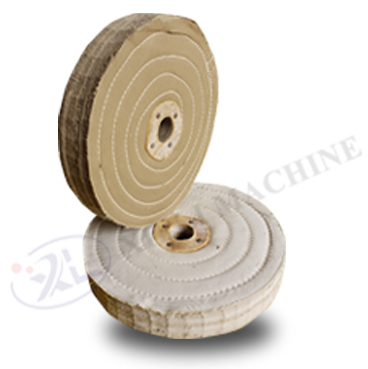

wholesale centerless grinder machines

3. Increased Production Speed Centerless grinders can operate at high speeds, allowing for greater throughput. The continuous feeding process significantly reduces cycle times, which means businesses can produce more parts within a shorter period. This efficiency not only enhances productivity but also enables businesses to respond quickly to market demands, ensuring they stay competitive in their respective fields.

4. Versatility Wholesale centerless grinder machines are capable of handling a wide variety of materials and part sizes. This versatility makes them an asset for manufacturers who need to produce different products. Whether it’s small medical components or larger automotive parts, these machines can be adjusted to accommodate different specifications and applications, providing a one-stop solution for various grinding needs.

5. Reduced Labor Costs Automation in manufacturing is increasingly important, and centerless grinding machines are designed with this in mind. By reducing the need for manual setup and operation, these machines can lower labor costs. Operators can focus on quality control and maintenance rather than being tied up with manual grinding tasks. This shift not only enhances efficiency but also improves the overall safety of the working environment.

6. Enhanced Surface Finish A key benefit of centerless grinding is its ability to provide superior surface finishes. Unlike other grinding processes, centerless grinding can achieve smoother finishes and superior geometrical accuracy. This capability is particularly beneficial in applications where surface finish is critical, such as in the production of bearings or precision rods.

7. Ease of Maintenance Wholesale centerless grinder machines are often designed with ease of maintenance in mind. Structured for durability, these machines require less frequent repairs than other types of grinding machines. Furthermore, their simple design means that routine maintenance can be performed quickly and efficiently, minimizing downtime and keeping production schedules on track.

Conclusion

In conclusion, wholesale centerless grinder machines offer a multitude of advantages that can significantly enhance a manufacturing operation. From cost efficiency and high precision to increased production speed and versatility, the benefits make them an essential investment for any business aiming to improve its competitive edge in the metalworking industry. By taking advantage of wholesale purchasing options, companies can not only save money but also position themselves for long-term growth by leveraging the capabilities of modern grinding technology. Transitioning to centerless grinding is not just a choice—it's a significant step toward greater efficiency and success in today's demanding marketplace.