The Emergence of Small Centerless Grinder Companies

In today's manufacturing landscape, precision and efficiency are paramount, especially in industries that require high-quality finishes and tight tolerances. Among the various machining technologies, centerless grinding stands out due to its ability to deliver superior results in a cost-effective manner. As the industry evolves, small centerless grinder companies are carving a niche for themselves, offering innovative solutions that cater to specific customer needs.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from the outside diameter of a workpiece. Unlike traditional grinding methods where the workpiece is held between two centers, centerless grinding allows for continuous production as components are fed through the grinding wheels. This results in increased efficiency and reduced cycle times, making it particularly advantageous for high-volume manufacturing.

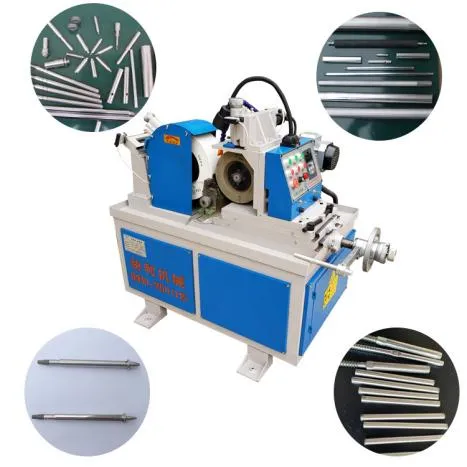

The process typically involves three main components the grinding wheel, the regulating wheel, and the workpiece. The grinding wheel performs the cutting action, while the regulating wheel controls the rotation and feed rate of the workpiece. This unique configuration enables centerless grinders to achieve precise dimensions while maintaining consistent surface finishes.

The Rise of Small Centerless Grinder Companies

In recent years, the market has witnessed the rise of small centerless grinder companies that focus on providing tailored solutions to meet diverse requirements. These firms often specialize in specific applications, offering customized machines that can handle unique geometries, materials, and production volumes.

One significant advantage of small companies is their agility. Unlike larger corporations that may have rigid structures and lengthy approval processes, small businesses can quickly adapt to changes in the market and respond to customer feedback. This flexibility allows them to innovate and develop new products at a faster pace, keeping them relevant in an ever-evolving industry.

small centerless grinder companies

Innovations and Advancements

Small centerless grinder manufacturers are not just participants in the market; they are also pioneers of innovation. Many of these companies invest heavily in research and development to improve their grinding technologies. Recent advancements include the integration of automation and digital controls, which enhance precision and reduce human error.

Moreover, these companies often focus on sustainability by developing energy-efficient machines that minimize waste and reduce environmental impact. The introduction of smart technology allows for real-time monitoring of the grinding process, enabling operators to detect issues before they lead to significant downtime or defects.

Customer-Centric Approaches

Another defining characteristic of small centerless grinder companies is their emphasis on customer-centric solutions. By working closely with clients, these firms can better understand their unique challenges and offer solutions that are specifically designed to meet those needs. This collaborative approach often results in machines that are more intuitive and user-friendly, enhancing the overall customer experience.

Furthermore, smaller manufacturers often provide personalized service and support, fostering long-term relationships with their clients. This level of dedication can significantly enhance customer loyalty, as businesses appreciate the attention to detail and commitment to their success.

Conclusion

As the demand for precision machining continues to grow, small centerless grinder companies are emerging as vital players in the industry. Their ability to provide customized solutions, embrace innovation, and prioritize customer relationships positions them well in a competitive market. As these companies continue to evolve, they are likely to play an increasingly important role in the future of manufacturing, reshaping the landscape of centerless grinding and driving advancements that benefit a wide range of industries.