Custom OSHA Centerless Grinder Enhancing Safety and Efficiency in Manufacturing

In the world of manufacturing, efficiency and safety are two paramount concerns. Centerless grinding is a crucial operation in this sector, valued for its ability to produce precision components with minimal human handling. However, the integration of safety standards, particularly those set forth by the Occupational Safety and Health Administration (OSHA), is essential in ensuring that these machines operate safely and effectively. Custom OSHA centerless grinders are designed to enhance both safety and performance in the manufacturing environment.

Understanding Centerless Grinding

Centerless grinding is a machining process utilized for producing cylindrical parts. Unlike traditional grinding methods, centerless grinding does not require the part to be held in place between centers. Instead, it relies on a regulating wheel and a grinding wheel to maintain the part’s position during the grinding operation. This unique setup allows for high-speed and efficient production, making it ideal for large runs of small to medium-sized parts.

The Importance of OSHA Compliance

OSHA was established to ensure safe working conditions across various industries, including manufacturing. Compliance with OSHA standards not only protects employees from workplace hazards but also enhances productivity. In the context of centerless grinding, OSHA regulations cover aspects such as machine guarding, noise exposure, and proper training for operators.

Custom OSHA centerless grinders are built with these regulations in mind

. These machines come equipped with safety features such as1. Enhanced Machine Guarding Proper guarding mechanisms prevent accidental contact with moving parts, significantly reducing the risk of injury. Custom grinders can be tailored to incorporate guards that conform to specific safety standards, providing operators with a safer working environment.

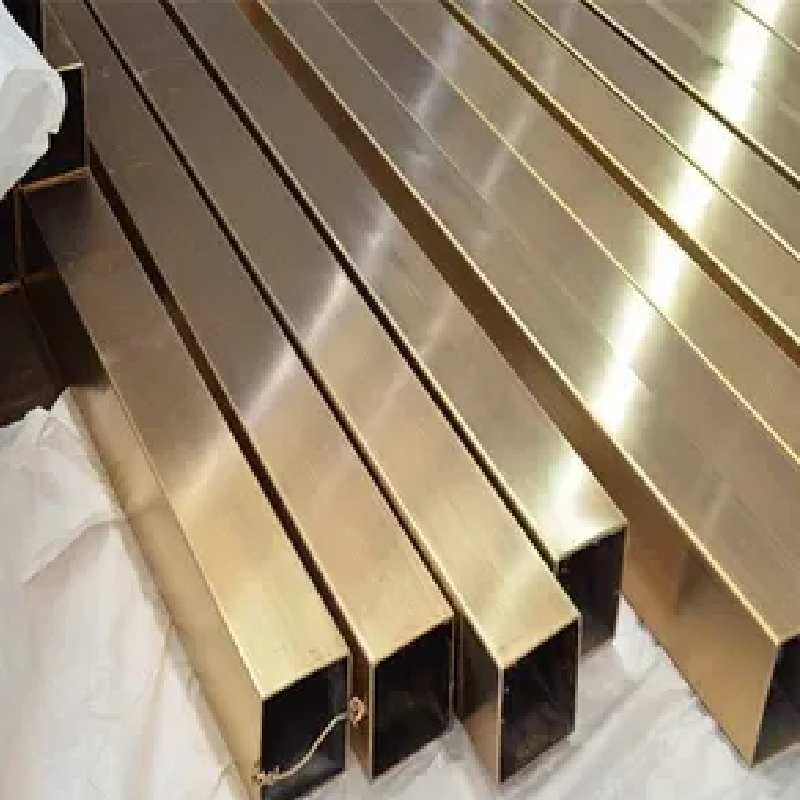

custom osha centerless grinder

2. Noise Reduction Technology Prolonged exposure to high noise levels can lead to hearing loss among operators. Custom grinders may include noise-dampening materials or designs that minimize the sound produced during operation, ensuring compliance with OSHA’s noise exposure limits.

3. Emergency Stop Mechanisms Quick access to emergency stops is critical in preventing accidents. Custom centerless grinders can integrate easily accessible emergency stop buttons, providing operators with immediate control in case of an incident.

4. Proper Training Guidelines An essential component of OSHA compliance is ensuring that employees receive adequate training on machine operation and safety protocols. Many manufacturers provide training programs tailored to the specific operations of their custom grinders, ensuring that all operators are well-informed on safety risks and operational best practices.

Benefits of Custom Design

The customization of OSHA centerless grinders offers significant advantages. Different manufacturing processes may demand specific features, such as varying wheel sizes or unique component configurations. Custom grinders allow manufacturers to tailor equipment to their specific needs, promoting not only operational efficiency but also production quality.

Additionally, investing in custom equipment can lead to long-term cost savings. While the initial investment may be higher compared to standard machines, the reliable performance and safety features of custom grinders can reduce downtime and minimize the risk of accidents, ultimately resulting in a more profitable operation.

Conclusion

Incorporating custom OSHA centerless grinders into manufacturing processes is a strategic move towards ensuring workplace safety and operational efficiency. By adhering to OSHA standards and prioritizing worker safety, manufacturers can create an environment that fosters productivity and protects their most valuable assets—their employees. As the manufacturing landscape continues to evolve, the need for advanced, compliant, and custom-designed grinding solutions will only grow, enhancing both safety and manufacturing outcomes across various industries. Investing in these tailored machines not only meets regulatory demands but also serves as a testament to a company's commitment to quality and safety in the workplace.