Buying a Centerless Grinder with a Surface Grinder

When it comes to precision manufacturing, the choice of grinding equipment can have a significant impact on throughput, precision, and overall product quality. Among the various types of grinding machines, centerless grinders and surface grinders are two of the most commonly used. If you’re considering investing in these machines, understanding their functionalities and how they complement each other is essential for making an informed decision.

What is a Centerless Grinder?

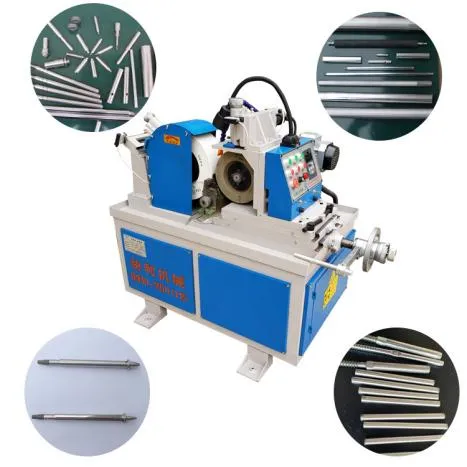

A centerless grinder is a type of cylindrical grinder that eliminates the need for a machine operator to manually position the workpiece. Instead, the workpiece is held in place by the interaction of the grinding wheel and a regulating wheel. This configuration allows for the continuous and efficient grinding of cylindrical parts without the need for complex setups. Centerless grinders are extensively used in industries where high-volume production is required, such as automotive, aerospace, and medical fields.

One of the main advantages of using a centerless grinder is its ability to achieve tight tolerances and smooth finishes without the risk of human error. This machine can efficiently handle various types of materials, including metals, plastics, and ceramics, making it versatile in application.

What is a Surface Grinder?

In contrast, a surface grinder is primarily used for flat surfaces, where it employs a rotating wheel to achieve a smooth finish across the surface of a workpiece. The surface grinder operates by moving the workpiece back and forth under the grinding wheel, making it ideal for tasks that require precision machining of flat surfaces. This type of machine is essential for creating flat, smooth finishes on parts that must fit together tightly or be aesthetically appealing.

Surface grinders come in various sizes and configurations to accommodate different workpiece dimensions and complexities. They can be manually operated or CNC-controlled for automation, which enhances productivity and consistency in surface finishing.

Complementing Each Other

When considering the purchase of both a centerless grinder and a surface grinder, it is vital to understand how they can work synergistically to enhance your manufacturing processes. The centerless grinder excels in machining cylindrical parts quickly and efficiently, while the surface grinder is perfect for achieving the desired finish on flat surfaces. By integrating both machines into your production line, you can significantly improve your ability to manufacture a variety of components with high precision and efficiency.

buy centerless grinder with a surface grinder

Key Considerations When Buying

When looking to buy a centerless grinder with a surface grinder, there are several factors to consider

1. Capacity and Size Determine the size of the workpieces you intend to grind. Both machines come in various sizes, so choose one that fits your operational needs.

2. Precision Requirements Assess the tolerances and surface finishes required for your products, as this will dictate the specifications of the grinders you need.

3. Automation Features Consider whether you require manual or CNC machines, as automation can improve efficiency and reduce the risk of human error.

4. Manufacturer Support Look into the reputation of the manufacturers, including warranty, customer support, and availability of replacement parts.

5. Budget Evaluate your budget for purchasing these machines, taking into account not only the initial investment but also the maintenance costs over time.

Conclusion

Investing in a centerless grinder with a surface grinder combination can greatly enhance your manufacturing capabilities. By carefully considering the factors outlined above, you can ensure that you choose the right machines to meet your operational needs, resulting in higher quality products and improved efficiency. As the demands of precision manufacturing continue to grow, having the right tooling is essential for staying competitive in the market.