The Importance of Inner Wall Polishing Machines in Manufacturing

In the realm of manufacturing, precision and quality are of utmost importance. One critical aspect often overlooked is the inner wall finishing of various products, particularly in industries like food processing, pharmaceuticals, and aerospace. This is where inner wall polishing machines come into play, providing a vital function in ensuring that components meet stringent quality standards.

Inner wall polishing machines are designed to enhance the surface finish of internal surfaces, primarily of pipes, tubes, and other cylindrical components. The polishing process removes imperfections, burrs, and reflections that can impede the performance of systems. A polished inner wall not only improves the aesthetic quality of a product but also significantly affects its functional properties, including flow efficiency, resistance to corrosion, and ease of cleaning.

One primary benefit of using an inner wall polishing machine is the improvement in hygiene. Industries such as food and beverages and pharmaceuticals require exceptionally clean surfaces to prevent contamination. Any roughness or inconsistencies can harbor bacteria or particles, leading to product contamination. By utilizing a polishing machine, manufacturers can achieve mirror-like finishes that are easier to sanitize. This is especially critical in maintaining compliance with safety and regulatory standards.

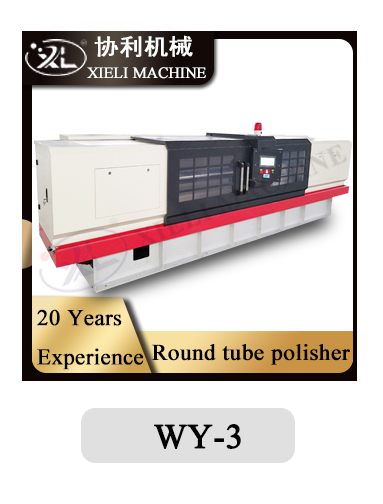

inner wall polishing machine products

In addition to hygiene, polished inner walls contribute to better fluid dynamics within pipes and tubes. The smoother surfaces facilitate better flow rates, reducing turbulence and allowing for more efficient transport of fluids. This enhanced performance can lead to significant cost savings in systems that require pumping or moving liquids through channels and pipes.

Another key aspect of inner wall polishing machines is their versatility. They can be utilized on a range of materials, including stainless steel, aluminum, and certain plastics. This adaptability makes them invaluable for manufacturers who work with multiple materials across different product lines. Furthermore, advancements in technology have led to the development of automated polishing systems that improve repeatability and reduce labor costs. These machines can be calibrated to ensure consistent finishes, regardless of the operator, enhancing overall production quality.

In summary, inner wall polishing machines play a crucial role in modern manufacturing processes. They ensure that internal surfaces meet high-quality standards necessary for hygiene and performance in various industries. As technology continues to evolve, these machines will likely become increasingly efficient and integral to maintaining the standards expected in today’s marketplace. Investing in inner wall polishing equipment is not just about production but also about guaranteeing the reliability and safety of the end products, making it a wise choice for any serious manufacturer.