DIY Centerless Grinder Factory Crafting Precision

The demand for precision machining in various industries has led to the emergence of DIY enthusiasts and small businesses looking to create their own centerless grinders. A DIY centerless grinder factory involves assembling components and utilizing engineering principles to produce a reliable machine that can deliver the precision needed for metalworking tasks.

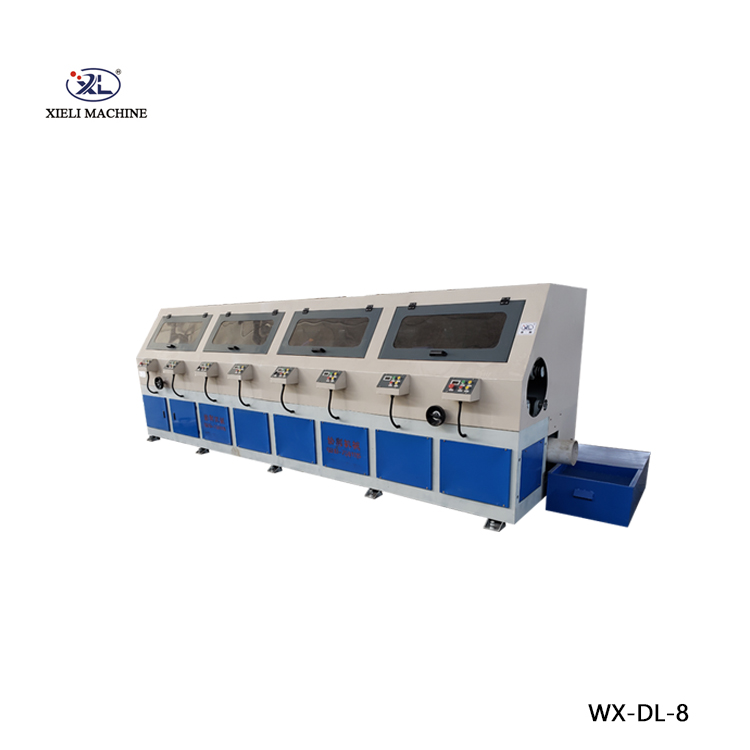

Centerless grinders operate on a simple yet effective principle the workpiece is held in place by a regulating wheel and a grinding wheel. The unique design allows for cylindrical parts to be ground without the need for fixtures. This technique is vital in producing parts with tight tolerances and smooth finishes, which is why many hobbyists and small-scale manufacturers have turned to building their own machines.

Essential Components

Creating a centerless grinder requires foundational knowledge of its components. The primary parts include the grinding wheel, regulating wheel, work rest, and drive mechanism. The grinding wheel, typically made of abrasive material, is responsible for removing material from the workpiece. It is crucial to select the right grit and bond for the grinding application to ensure optimal performance.

The regulating wheel controls the speed of the workpiece and its feed rate. This element plays a significant role in achieving the desired finish and dimensional accuracy. A well-designed work rest supports the workpiece during grinding, enhancing stability and precision. Lastly, the drive mechanism, which can be powered by an electric motor, transfers power to the wheels and maintains consistent rotation.

Designing the Factory

diy centerless grinder factory

When establishing a DIY centerless grinder factory, space and layout are vital considerations. The workspace should be sufficiently sized to accommodate equipment and allow for safe operation. Additionally, proper ventilation and dust collection systems are essential to ensure a safe working environment.

Blueprints should be created to visualize the placement of machines, tools, and materials. Incorporating workbenches for assembly, storage for tools and spare parts, and a designated area for troubleshooting and maintenance will streamline operations.

Safety Measures

Safety is paramount when dealing with machinery. Protective equipment, including gloves, goggles, and hearing protection, should be worn at all times. Training for all operators is essential to prevent accidents and ensure proper handling of tools and materials. Furthermore, implementing safety protocols, such as emergency stop switches and machine guards, can minimize risks.

Conclusion

Embarking on the journey to establish a DIY centerless grinder factory can be both exciting and rewarding. With careful planning, dedication, and attention to detail, enthusiasts can create machines that not only meet their specific needs but also contribute to the advancement of precision machining. The skills gained from this project can lead to innovative designs, improved techniques, and a deeper understanding of the engineering processes behind manufacturing. Ultimately, a DIY centerless grinder factory opens up a realm of possibilities in the world of machining, empowering individuals to turn their ideas into reality.