Centerless Tube Polishing Machine Exporters An Overview of the Industry

In today’s competitive manufacturing landscape, the demand for high-quality surface finishes on metal components has never been more critical. Among the various machines that serve this purpose, the centerless tube polishing machine has emerged as a significant player. These machines are specifically designed to enhance the surface quality of cylindrical tubes, ensuring they meet the stringent standards required in industries such as automotive, aerospace, and construction. As a result, exporters of centerless tube polishing machines are experiencing a surge in demand, both locally and internationally.

What is a Centerless Tube Polishing Machine?

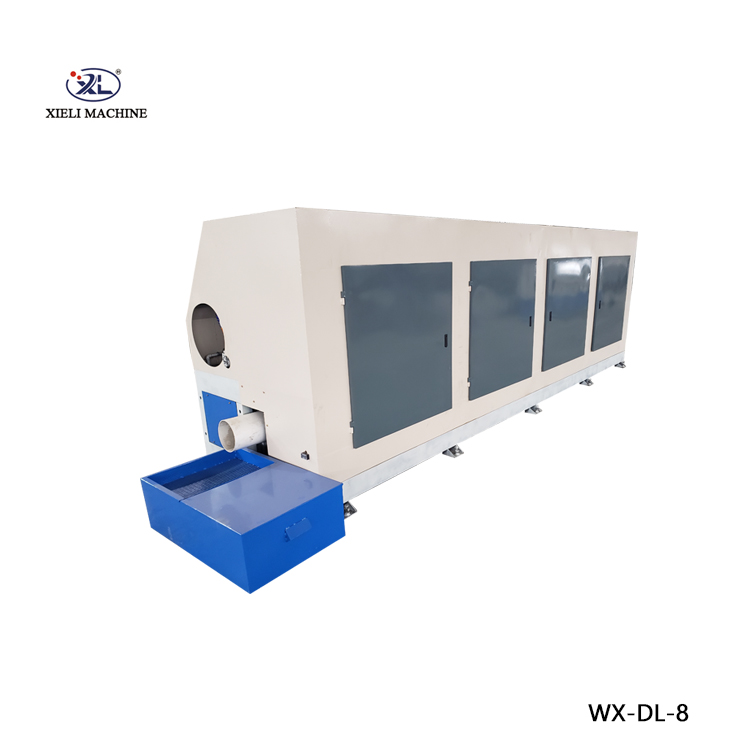

A centerless tube polishing machine is a specialized equipment designed for the polishing of cylindrical tubes without the need for a central axis to support the tube during the polishing process. Unlike conventional polishing machines, centerless machines allow for continuous feeding of workpieces, significantly improving throughput and operational efficiency. This method is particularly useful for polishing tubes made from materials such as stainless steel, aluminum, and various alloys.

The key components of a centerless tube polishing machine typically include

1. Grinding Wheels These are used to remove material from the surface of the tube, shaping it to the desired finish. 2. Polishing Wheels After the initial grinding, the polishing wheels refine the surface to a smooth, shiny finish. 3. Conveyor System This system facilitates the continuous feed of tubes into the machine, automating and streamlining the polishing process.

The Growing Demand for Exporters

Exporters of centerless tube polishing machines are experiencing considerable growth due to several factors

1. Emerging Markets Countries in Asia, Africa, and South America are rapidly industrializing, leading to increased demand for high-quality polishing equipment. As local manufacturers seek to improve their product offerings, the need for advanced machinery becomes paramount.

centerless tube polishing machine exporters

2. Technological Advancements The integration of technology into manufacturing processes has led to the development of more efficient and user-friendly polishing machines. Exporters who continually innovate and offer state-of-the-art equipment are likely to gain a competitive edge in the global market.

3. Quality Standards Industries that rely on polished tubes often have stringent quality requirements. Exporters that provide machines capable of meeting these standards find themselves in high demand. Compliance with international quality certifications can significantly enhance an exporter’s reputation and marketability.

Key Markets for Exporters

The main markets for centerless tube polishing machine exporters include

- North America The region is home to a robust manufacturing sector, particularly in the automotive and aerospace industries. The demand for precision-engineered components ensures a steady market for polishing machines.

- Europe European countries, with their focus on quality and sustainability, represent a significant opportunity for exporters. Compliance with environmental and quality regulations can significantly impact machine sales in this region.

- Asia-Pacific This region, particularly China and India, is witnessing rapid industrial growth. The increasing emphasis on high-quality manufacturing processes has propelled the demand for advanced polishing machinery.

Conclusion

In summary, the industry of centerless tube polishing machine exporters is thriving in response to the growing needs of various sectors for high-quality surface finishes. As companies worldwide seek to enhance their manufacturing capabilities, the role of these machines becomes increasingly critical. Exporters that focus on innovation, compliance with international standards, and understanding their target markets will likely succeed in this competitive environment. With continued advancements in technology and a broadening scope of applications, the future of centerless tube polishing machine exporters appears promising. In this ever-evolving landscape, adaptability and foresight will be the keys to unlocking new opportunities and ensuring long-term success.