CE Certification for Small Centerless Grinders Ensuring Quality and Safety in Precision Engineering

In the world of precision engineering, small centerless grinders play a vital role in achieving high-quality surface finishes and dimensional accuracy for various components. Often used in manufacturing processes for industries such as automotive, aerospace, and medical devices, these machines demand strict adherence to safety and quality standards. One such benchmark is the CE certification, which marks a product's compliance with European health, safety, and environmental protection legislation. Understanding CE certification's significance in small centerless grinders is crucial for manufacturers and users alike.

What is CE Certification?

CE certification is a mark that indicates a product meets European Union (EU) standards for safety, health, and environmental requirements. The CE stands for Conformité Européenne, which translates to European Conformity. This certification is mandatory for many products sold within the EU, including machinery and equipment. It assures consumers and businesses that the product is safe to use and complies with all relevant EU directives, such as the Machinery Directive and the Low Voltage Directive.

Importance of CE Certification for Small Centerless Grinders

1. Safety Assurance Small centerless grinders operate with precision at high speeds, which can pose significant risks if not designed correctly. CE certification ensures that the grinder meets safety requirements to protect operators and maintenance personnel from potential hazards, such as electrical failures, mechanical breakdowns, or user mishaps.

2. Market Access For manufacturers looking to enter the European market, CE certification is often a prerequisite. Without it, products cannot be sold within the EU, limiting the market reach of a manufacturer. Obtaining CE certification opens the door to new business opportunities and enhances the company's credibility.

3. Quality Assurance The process of obtaining CE certification involves rigorous testing and evaluation of a product's design and performance. This ensures that the small centerless grinder meets high standards of quality and reliability, which ultimately benefits end-users through improved performance and durability.

4. Environmental Compliance The CE marking also signifies that the product adheres to environmental regulations, minimizing its ecological footprint. For manufacturers, this compliance is increasingly important in an era where environmental sustainability is a significant concern among consumers and regulatory bodies.

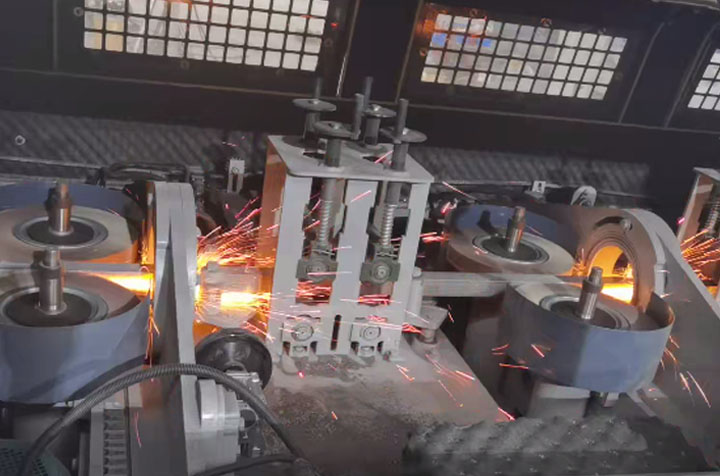

ce certification small centerless grinder

The Certification Process

The CE certification process for small centerless grinders typically includes several key steps

1. Risk Assessment Manufacturers must conduct a thorough risk assessment to identify potential hazards associated with the grinder's operation. This assessment forms the basis for determining necessary safety measures.

2. Testing and Evaluation Following the risk assessment, the grinder undergoes testing to verify that it meets applicable standards. This may involve performance tests, electrical safety checks, and noise assessments.

3. Technical Documentation Manufacturers are required to compile technical documentation that outlines the grinder's design, specifications, and compliance with relevant standards. This documentation serves as proof of conformity and must be maintained for future reference.

4. Declaration of Conformity Once all tests and evaluations are successfully passed, the manufacturer issues a Declaration of Conformity. This formal statement confirms that the grinder meets all necessary requirements and is eligible to bear the CE mark.

5. Periodic Reviews and Updates CE certification is not a one-time process. Manufacturers must regularly review and update their compliance to accommodate changes in regulations, technology, or design improvements.

Conclusion

CE certification for small centerless grinders is an essential component of ensuring safety, quality, and environmental compliance in precision engineering. As businesses increasingly operate on a global scale, understanding and achieving CE certification has become paramount for manufacturers looking to succeed in the competitive European market. By adhering to these standards, manufacturers not only protect their operators and customers but also enhance their reputation and expand their reach in the industry. In today's fast-evolving manufacturing landscape, CE certification serves as a hallmark of excellence and responsibility.