The Best CNC Centerless Grinder for Sale A Comprehensive Guide

In the world of manufacturing, precision and efficiency are paramount. Among the various machining processes, centerless grinding stands out for its ability to produce high-precision components while maintaining high throughput. A CNC centerless grinder is an invaluable tool for manufacturers looking to enhance productivity and quality. If you are in the market for a CNC centerless grinder, this article will guide you through the best options available and what to consider when making your purchase.

Understanding CNC Centerless Grinding

Centerless grinding is a method that allows for the grinding of cylindrical parts without the use of a spindle. Instead, the workpiece is supported by a blade and the grinder wheel, enabling it to rotate freely. This process is particularly advantageous for producing parts with tight tolerances and perfect surface finishes. CNC (Computer Numerical Control) centerless grinders use advanced automation to enhance precision, reduce manual labor, and increase production speeds.

Key Features to Consider

1. Grinding Capacity When selecting a CNC centerless grinder, consider the size and weight of the parts you will be working with. Look for a machine that accommodates your specific part dimensions and weight requirements.

2. Accuracy and Precision The best CNC centerless grinders provide high accuracy and can achieve tolerances within a few micrometers. Ensure that the machine you choose has a reliable control system and capable wheel dressing mechanisms.

3. Automation and Technology Look for models that incorporate advanced technology, such as touch screen interfaces, programmable controls, and automated feeding mechanisms. This can significantly reduce setup time and enhance operational efficiency.

4. Versatility A versatile machine can handle a variety of materials and sizes, which can be beneficial for businesses that work with different types of components. Some machines offer quick changeovers, allowing you to switch between different grinding operations seamlessly.

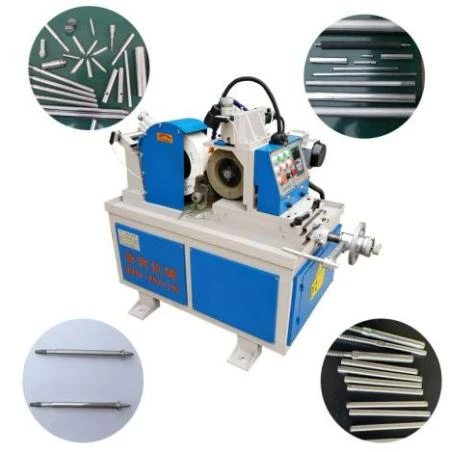

best cnc centerless grinder for sale

5. Manufacturer Reputation Do thorough research on manufacturers and their products. Look for companies with a good track record, positive customer reviews, and robust support services. Brands that have been in the industry for years are often dependable choices.

Recommended Models

Here are some of the best CNC centerless grinders currently available on the market

1. Cincinnati 220-8 Known for its durability and precision, the Cincinnati 220-8 model is a popular choice among manufacturers. Equipped with advanced CNC technology and a robust design, it can handle various materials and provides a smooth grinding process.

2. Royal Master TG-12x4 This grinder is renowned for its versatility and compact footprint. It is ideal for grinding small parts and can be customized for specific applications. Its user-friendly controls make it easy to operate even for inexperienced operators.

3. Koyo Machinery GKE The Koyo GKE series is known for its high-speed capabilities and precision. It features an easy-to-use interface and can accommodate a wide range of part sizes, making it suitable for various manufacturing needs.

Conclusion

Investing in a CNC centerless grinder can significantly enhance your manufacturing capabilities, ensuring that you produce high-quality parts efficiently. When choosing the best CNC centerless grinder for sale, consider factors such as grinding capacity, precision, automation features, and the manufacturer's reputation. By carefully evaluating your options and selecting the right machine, you can improve your production processes and meet the demands of your industry. Make sure to consult industry experts and participate in demonstrations to make an informed decision that aligns with your business needs.