The Advancements and Benefits of Multi-Head Automatic Polishing Machines

In the world of manufacturing and surface finishing, achieving a flawless finish on products is critical. This necessity has fueled the development of sophisticated machinery that enhances efficiency and quality—one notable innovation being the multi-head automatic polishing machine. These machines are transforming industries such as automotive, aerospace, and consumer electronics by automating the polishing process, increasing output, and ensuring consistent results.

Understanding Multi-Head Automatic Polishing Machines

A multi-head automatic polishing machine is designed to polish various surfaces simultaneously using multiple heads equipped with different types of polishing tools. This functionality allows for the swift processing of numerous components in a single operation, significantly reducing the time required for manual polishing. These machines can handle various materials including metals, plastics, and ceramics, making them versatile choices for numerous applications.

Key Features

1. Efficiency and Speed The multi-head design allows for simultaneous polishing of multiple items, drastically reducing processing times compared to traditional single-head machines. This increase in efficiency translates directly into enhanced productivity for manufacturers.

2. Consistency and Quality Control Automated polishing ensures that each piece receives uniform treatment. This technological advancement minimizes human error and variability, resulting in a predictable and high-quality finish that is crucial for high-end products.

3. Customization Many multi-head polishing machines come with adjustable settings that allow operators to change polishing speeds, pressure, and the angle of the polishing heads. This adaptability makes it possible to tailor the polishing process to different materials and desired finishes—ranging from a high-gloss shine to a matte surface.

4. Integrated Technology The latest models are equipped with advanced control systems and sensors that monitor the polishing process in real-time. This technology helps to detect discrepancies in pressure and speed, automatically adjusting as needed to maintain quality standards.

5. Safety Features Automatic polishing machines are designed with safety in mind, often including mechanisms like emergency stop buttons, safety shields, and automated shut-off features that protect operators and enhance workplace safety.

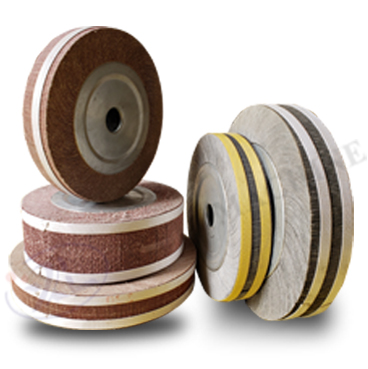

multi-head automatic polishing machine product

Applications

The utility of multi-head automatic polishing machines spans various industries

- Automotive Used for polishing car bodies and components, these machines help manufacturers achieve a smooth finish that is essential for aesthetic appeal and corrosion resistance.

- Aerospace Precision in polishing is vital in aerospace applications to not only enhance appearances but also to ensure aerodynamics and performance. Multi-head polishing machines help maintain stringent industry standards.

- Consumer Electronics Manufacturers of smartphones, laptops, and other devices utilize these machines to create sleek, polished finishes that attract consumers.

- Furniture and Home Appliances High-end furniture and appliances benefit from the quick, consistent finishing that these machines provide, enhancing product quality and customer satisfaction.

Conclusion

The emergence of multi-head automatic polishing machines marks a significant leap forward in manufacturing technology. Their ability to efficiently produce high-quality finishes across a range of industries makes them indispensable in modern production lines. As manufacturers continue to seek ways to improve productivity and quality, these machines will undoubtedly play a pivotal role in shaping the future of surface finishing. Investing in such technology not only streamlines operations but also ensures that businesses remain competitive in an ever-evolving marketplace.

In conclusion, multi-head automatic polishing machines are a testament to the convergence of automation and precision engineering, undoubtedly elevating standards in manufacturing processes across the globe. As technology advances, we can anticipate even more sophisticated features and capabilities that will further enhance the effectiveness of these remarkable machines.